Siro spinning produces yarn by twisting two rovings together, resulting in stronger, finer, and smoother yarn suitable for high-quality fabrics, while open-end spinning uses a rotor to create yarn quickly but with a coarser texture and less strength. Your choice depends on the desired fabric characteristics, as siro spinning excels in durability and appearance, whereas open-end spinning offers faster production for heavier textiles.

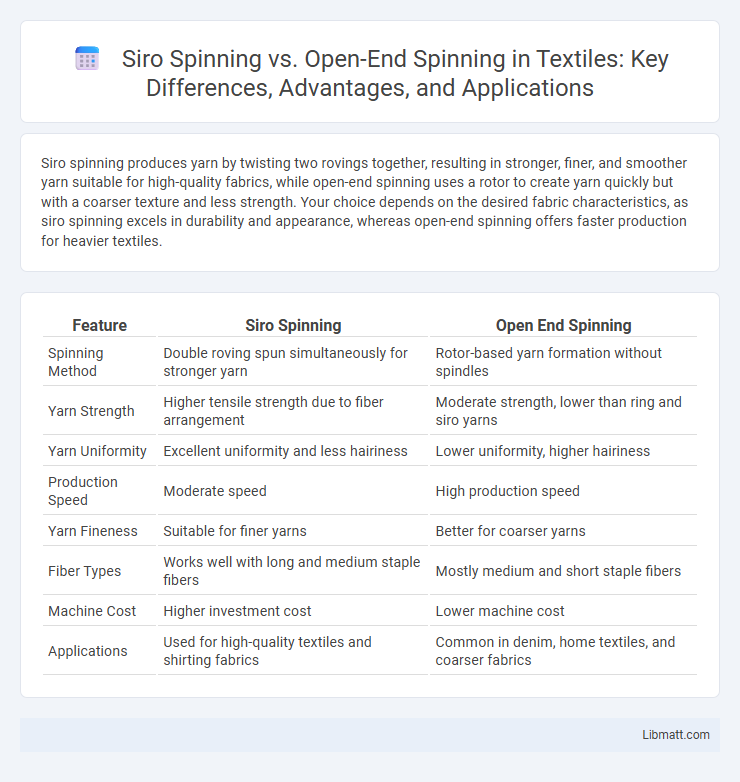

Table of Comparison

| Feature | Siro Spinning | Open End Spinning |

|---|---|---|

| Spinning Method | Double roving spun simultaneously for stronger yarn | Rotor-based yarn formation without spindles |

| Yarn Strength | Higher tensile strength due to fiber arrangement | Moderate strength, lower than ring and siro yarns |

| Yarn Uniformity | Excellent uniformity and less hairiness | Lower uniformity, higher hairiness |

| Production Speed | Moderate speed | High production speed |

| Yarn Fineness | Suitable for finer yarns | Better for coarser yarns |

| Fiber Types | Works well with long and medium staple fibers | Mostly medium and short staple fibers |

| Machine Cost | Higher investment cost | Lower machine cost |

| Applications | Used for high-quality textiles and shirting fabrics | Common in denim, home textiles, and coarser fabrics |

Introduction to Siro Spinning and Open End Spinning

Siro spinning uses two rovings fed simultaneously into the drafting zone, producing stronger yarn with improved evenness and reduced hairiness compared to conventional ring spinning. Open end spinning, also known as rotor spinning, separates fibers through a high-speed rotor, enabling faster production but typically resulting in coarser yarns with lower tensile strength. Both methods cater to different textile applications, balancing quality and speed in yarn manufacturing.

Principles of Siro Spinning

Siro spinning involves simultaneous drafting of two rovings merged into a single strand before twisting, resulting in a yarn with enhanced strength and uniformity compared to open end spinning. This process maintains fiber alignment and creates less hairiness, making the yarn suitable for high-quality fabric production. Your choice of Siro spinning ensures improved yarn evenness and durability, distinct from the coarser structure of open end spun yarns.

Fundamentals of Open End Spinning

Open End Spinning, also known as rotor spinning, fundamentally differs from Siro spinning by using a high-speed rotor to twist fibers into yarn, eliminating the need for a spindle. This process allows for faster production and lower operational costs, producing yarns with less strength but higher bulkiness compared to Siro spinning. Understanding Open End Spinning can help you select the right method based on the desired yarn quality and production efficiency.

Key Differences Between Siro and Open End Spinning

Siro spinning combines two rovings to create a yarn with enhanced strength and uniformity, whereas open end spinning uses a rotor to twist fibers into yarn, producing coarser and less uniform threads. Siro spinning offers higher productivity and finer yarn quality suitable for apparel fabrics, while open end spinning excels in bulkier, lower-cost yarn production for home textiles. The key difference lies in the fiber feeding mechanism and yarn characteristics, with Siro spinning delivering better fiber alignment and reduced hairiness compared to open end spinning.

Yarn Quality Comparison: Siro vs Open End

Siro spinning produces yarn with superior strength, uniformity, and less hairiness compared to open-end spinning, resulting in higher-quality fabrics ideal for premium textiles. The compact yarn formation in Siro spinning enhances tensile strength and reduces pilling, while open-end yarns demonstrate lower elongation and are more prone to fiber fly and unevenness. Consequently, Siro yarn is preferred for finer, softer fabrics with better appearance, whereas open-end yarns are suited for coarser, more cost-effective applications.

Production Efficiency and Cost Analysis

Siro spinning offers higher production efficiency by producing stronger yarn with less twist, reducing breakage rates and minimizing downtime compared to open end spinning, which operates at higher speeds but often yields lower-quality yarn. Cost analysis reveals that while open end spinning has lower initial equipment costs and is faster, Siro spinning reduces overall production expenses through decreased waste, less energy consumption, and fewer repair costs. The balance between speed and yarn quality ultimately positions Siro spinning as a cost-effective choice for mills prioritizing durability and efficiency in yarn production.

Fiber Versatility and Material Compatibility

Siro spinning offers enhanced fiber versatility by efficiently blending various staple fibers such as cotton, viscose, and polyester, resulting in superior yarn uniformity and strength compared to open end spinning, which primarily handles coarser fibers. The Siro process supports finer counts and delicate materials, making it ideal for producing high-quality yarns from a wide range of natural and synthetic fibers. In contrast, open end spinning exhibits limited material compatibility, favoring shorter, coarser fibers and generating yarns with lower tensile strength and uniformity.

Applications in Textile Manufacturing

Siro spinning produces stronger and finer yarns ideal for high-quality textiles such as shirting, suiting, and knitwear, where durability and smooth texture are essential. Open end spinning suits mass production of coarser yarns used in home textiles, towels, and denim, offering higher productivity but less uniformity and strength. Your choice depends on the specific application requirements for fabric quality, production volume, and cost efficiency in textile manufacturing.

Environmental Impact and Sustainability

Siro spinning consumes less water and energy compared to open end spinning, significantly reducing its environmental footprint. Your choice of Siro spinning promotes sustainability by generating less waste and enabling better resource efficiency throughout the textile production process. This method supports eco-friendly manufacturing practices crucial for minimizing the fashion industry's impact on the planet.

Future Trends in Spinning Technology

Siro spinning technology offers enhanced yarn strength and uniformity by twisting two rovings simultaneously, while open-end spinning excels in high-speed production and cost efficiency. Future trends focus on integrating automation, AI-driven quality control, and energy-efficient processes to optimize both methods, improving yarn consistency and reducing waste. Your choice between Siro and open-end spinning will increasingly depend on balancing production speed with fabric quality demands in smart textile manufacturing.

Siro spinning vs Open end spinning Infographic

libmatt.com

libmatt.com