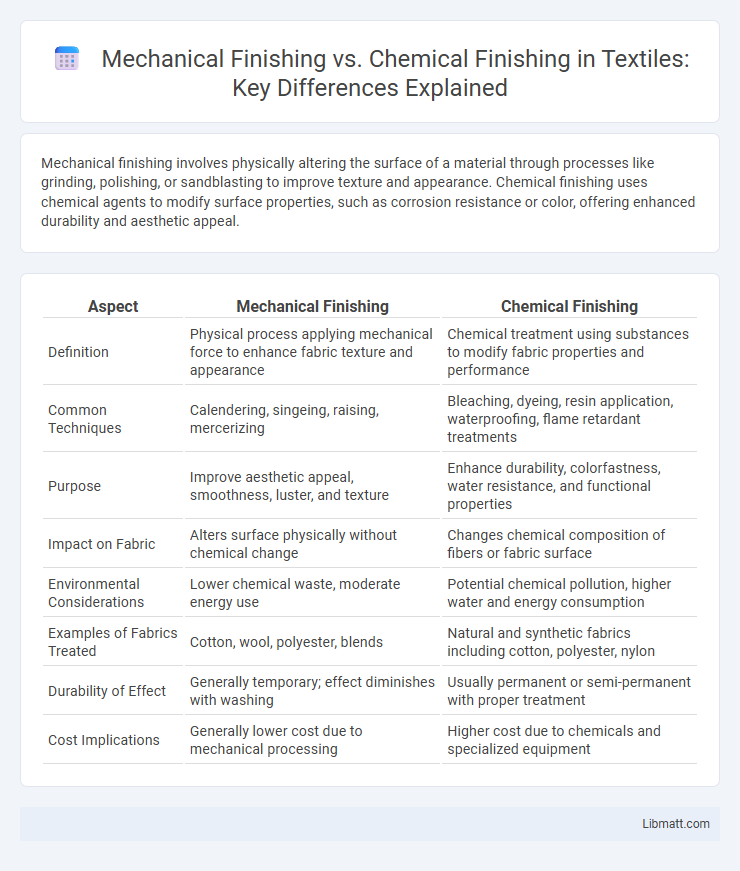

Mechanical finishing involves physically altering the surface of a material through processes like grinding, polishing, or sandblasting to improve texture and appearance. Chemical finishing uses chemical agents to modify surface properties, such as corrosion resistance or color, offering enhanced durability and aesthetic appeal.

Table of Comparison

| Aspect | Mechanical Finishing | Chemical Finishing |

|---|---|---|

| Definition | Physical process applying mechanical force to enhance fabric texture and appearance | Chemical treatment using substances to modify fabric properties and performance |

| Common Techniques | Calendering, singeing, raising, mercerizing | Bleaching, dyeing, resin application, waterproofing, flame retardant treatments |

| Purpose | Improve aesthetic appeal, smoothness, luster, and texture | Enhance durability, colorfastness, water resistance, and functional properties |

| Impact on Fabric | Alters surface physically without chemical change | Changes chemical composition of fibers or fabric surface |

| Environmental Considerations | Lower chemical waste, moderate energy use | Potential chemical pollution, higher water and energy consumption |

| Examples of Fabrics Treated | Cotton, wool, polyester, blends | Natural and synthetic fabrics including cotton, polyester, nylon |

| Durability of Effect | Generally temporary; effect diminishes with washing | Usually permanent or semi-permanent with proper treatment |

| Cost Implications | Generally lower cost due to mechanical processing | Higher cost due to chemicals and specialized equipment |

Introduction to Mechanical and Chemical Finishing

Mechanical finishing involves physical processes such as grinding, polishing, and blasting to enhance surface texture and durability. Chemical finishing uses chemical reactions like etching, plating, or passivation to alter surface properties, improving corrosion resistance and appearance. Your choice between mechanical and chemical finishing depends on the desired surface characteristics and application requirements.

Defining Mechanical Finishing

Mechanical finishing involves physical processes like grinding, polishing, and sanding to enhance surface texture and appearance by removing imperfections or creating specific finishes. It improves dimensional accuracy, surface smoothness, and can increase durability by refining surface structure without altering chemical composition. Mechanical finishing is essential in industries such as automotive, aerospace, and metal fabrication where precise surface characteristics are critical.

Overview of Chemical Finishing

Chemical finishing enhances material surfaces by applying chemical solutions that alter their properties, such as corrosion resistance, color, or texture. Common chemical finishing processes include anodizing, electroplating, and passivation, which improve durability and aesthetic appeal. These methods are preferred over mechanical finishing for intricate shapes or surfaces requiring uniform treatment without abrasion.

Key Differences Between Mechanical and Chemical Finishing

Mechanical finishing involves physical processes such as grinding, polishing, or tumbling to improve surface texture, while chemical finishing uses reactive substances like acids or alkalis to alter surface properties. Mechanical methods primarily enhance dimensional accuracy and surface smoothness, whereas chemical finishing targets corrosion resistance and surface passivation. The choice between mechanical and chemical finishing depends on material type, desired surface characteristics, and application-specific requirements.

Advantages of Mechanical Finishing

Mechanical finishing offers precise surface refinement by physically altering the material through grinding, polishing, or blasting, which enhances durability and wear resistance. This process often results in faster turnaround times and lower environmental impact compared to chemical finishing, as it avoids the use of hazardous substances. Choosing mechanical finishing ensures your components achieve a consistent texture and improved mechanical properties without the risks associated with chemical exposure.

Benefits of Chemical Finishing

Chemical finishing enhances surface properties by providing superior corrosion resistance, improved adhesion for coatings, and increased durability compared to mechanical finishing. Your products benefit from uniform treatment, even on complex geometries, ensuring consistent quality and extended lifespan. This process also allows for precise control over surface texture and appearance, optimizing performance in demanding environments.

Limitations and Challenges of Mechanical Finishing

Mechanical finishing faces limitations such as uneven surface results, potential for surface damage, and challenges in achieving precise tolerances on complex parts. The process often requires significant manual labor and can be time-consuming, reducing efficiency in high-volume production. Your choice between mechanical and chemical finishing should consider these challenges alongside the material type and desired surface quality.

Drawbacks Associated with Chemical Finishing

Chemical finishing processes often involve the use of hazardous substances that pose environmental and health risks due to toxic effluents and volatile organic compounds. These chemicals can degrade fabric strength and alter the texture, potentially reducing the durability and lifespan of textiles. Strict regulatory compliance and waste treatment requirements further increase operational costs and complexity in chemical finishing applications.

Selection Criteria: When to Use Mechanical or Chemical Finishing

Mechanical finishing is preferred for parts requiring surface texture improvement, dimensional accuracy, and removal of burrs or sharp edges, especially in metals and hard materials. Chemical finishing is ideal for enhancing corrosion resistance, achieving uniform surface coatings, or smoothing complex shapes where mechanical methods might cause damage. Selection depends on factors such as material type, desired surface properties, production volume, and environmental considerations.

Future Trends in Finishing Technologies

Future trends in mechanical finishing highlight automation and precision, integrating robotic systems and advanced abrasives to enhance efficiency and consistency in surface treatments. Chemical finishing is evolving with sustainable, eco-friendly formulations that reduce hazardous waste while improving corrosion resistance and surface quality through innovations in nanotechnology. Hybrid finishing technologies combining mechanical and chemical methods are emerging, offering tailored solutions for complex materials and industries such as aerospace and automotive manufacturing.

Mechanical finishing vs Chemical finishing Infographic

libmatt.com

libmatt.com