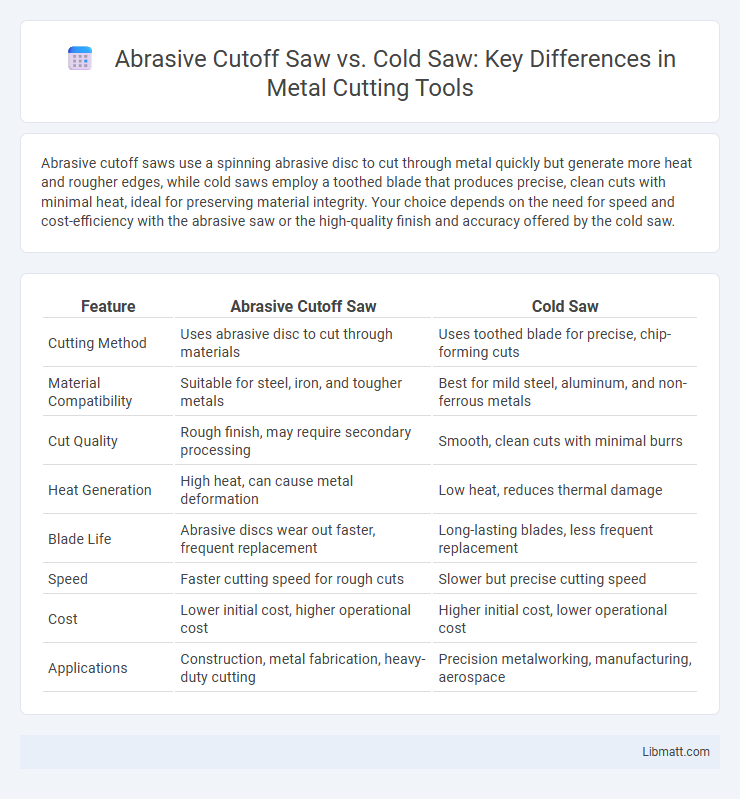

Abrasive cutoff saws use a spinning abrasive disc to cut through metal quickly but generate more heat and rougher edges, while cold saws employ a toothed blade that produces precise, clean cuts with minimal heat, ideal for preserving material integrity. Your choice depends on the need for speed and cost-efficiency with the abrasive saw or the high-quality finish and accuracy offered by the cold saw.

Table of Comparison

| Feature | Abrasive Cutoff Saw | Cold Saw |

|---|---|---|

| Cutting Method | Uses abrasive disc to cut through materials | Uses toothed blade for precise, chip-forming cuts |

| Material Compatibility | Suitable for steel, iron, and tougher metals | Best for mild steel, aluminum, and non-ferrous metals |

| Cut Quality | Rough finish, may require secondary processing | Smooth, clean cuts with minimal burrs |

| Heat Generation | High heat, can cause metal deformation | Low heat, reduces thermal damage |

| Blade Life | Abrasive discs wear out faster, frequent replacement | Long-lasting blades, less frequent replacement |

| Speed | Faster cutting speed for rough cuts | Slower but precise cutting speed |

| Cost | Lower initial cost, higher operational cost | Higher initial cost, lower operational cost |

| Applications | Construction, metal fabrication, heavy-duty cutting | Precision metalworking, manufacturing, aerospace |

Introduction to Abrasive Cutoff Saws and Cold Saws

Abrasive cutoff saws use composite abrasive wheels to cut through metals and hard materials with rapid, rough cuts ideal for steel and concrete. Cold saws utilize toothed circular blades operating at lower speeds to produce precise, burr-free cuts with minimal heat, preserving your material's integrity. Choosing between these saws depends on the required cut quality and material type for your project.

Key Differences: Abrasive Cutoff Saw vs Cold Saw

Abrasive cutoff saws use a high-speed abrasive disc to cut through tough metals and materials by grinding, producing significant heat and sparks, while cold saws utilize a toothed blade with low-speed, high-torque cutting that generates minimal heat and a clean, precise cut. Abrasive cutoff saws are ideal for quick, rough cuts on hard materials but result in more material loss and blade wear, whereas cold saws are preferred for precise, burr-free cuts with minimal kerf, preserving material integrity. The choice between these saws depends on specific cutting requirements such as material type, desired finish, and production speed.

Cutting Mechanism and Blade Composition

Abrasive cutoff saws use a rapidly spinning abrasive disc to grind through materials, making them ideal for cutting hard metals with a versatile and cost-effective blade composition often made from aluminum oxide or silicon carbide. Cold saws employ a toothed, circular metal blade that cuts by shearing, maintaining a lower cutting temperature and producing cleaner, precise cuts with blades typically composed of high-speed steel (HSS) or carbide-tipped materials. Your choice depends on whether you prioritize speed and rough cuts or precision and smooth finishes in metalworking applications.

Materials Each Saw Is Best Suited For

Abrasive cutoff saws excel at cutting hard materials such as stainless steel, cast iron, and concrete due to their high-speed abrasive wheels that grind through tough surfaces. Cold saws are ideal for cutting ferrous and non-ferrous metals like aluminum, brass, and mild steel, providing clean, precise cuts with minimal heat and material deformation. Your choice depends on the material type, as abrasive saws handle harder, more abrasive substances while cold saws maintain sharp edges on softer metals.

Precision and Cut Quality Comparison

Abrasive cutoff saws produce rougher cuts with more heat-affected zones, leading to greater material deformation and lower dimensional accuracy. Cold saws utilize a toothed blade that cuts at low speeds, minimizing heat generation and preserving material integrity, resulting in cleaner, more precise cuts with superior edge quality. The precision of cold saws makes them ideal for applications demanding tight tolerances and smooth finishes, outperforming abrasive cutoff saws in cut quality and accuracy.

Speed and Efficiency in Industrial Applications

Abrasive cutoff saws excel in speed due to their high RPM and aggressive cutting action, making them ideal for quick cuts on hard materials like metal and concrete. Cold saws deliver superior efficiency by producing precise, burr-free cuts with minimal heat generation, reducing the need for secondary finishing processes in industrial settings. Your choice between these saws impacts operational speed and efficiency, depending on the material and quality requirements.

Safety Considerations and Operation Risks

Abrasive cutoff saws generate high friction and sparks, increasing the risk of burns, flying debris, and wheel shattering, requiring strict use of personal protective equipment (PPE) and proper guard installation. Cold saws operate at lower speeds with toothed blades that produce less heat and minimal sparks, significantly reducing burn hazards and the likelihood of kickback, making them safer for precise metal cutting. Ensuring your workspace is well-ventilated and maintaining the equipment properly are critical for minimizing operational risks with both saw types.

Maintenance Requirements and Costs

Abrasive cutoff saws require frequent blade replacements and higher maintenance due to increased wear from friction, leading to elevated operational costs. Cold saws use a circular toothed blade that lasts longer and needs less frequent maintenance, reducing downtime and overall expenses. Investing in a cold saw typically results in cost savings and less frequent service compared to abrasive cutoff saws.

Initial Investment and Long-Term Value

Abrasive cutoff saws require a lower initial investment, making them suitable for budget-conscious startups, while cold saws demand higher upfront costs due to precision engineering and advanced blade technology. Over time, cold saws offer greater long-term value through superior blade longevity, reduced material waste, and enhanced cut quality, minimizing operational expenses. Abrasive saws may incur higher maintenance and blade replacement costs, impacting overall cost efficiency in heavy-duty, precision applications.

Choosing the Right Saw for Your Metalworking Needs

When choosing the right saw for your metalworking needs, an abrasive cutoff saw excels in cutting hard metals quickly but generates more heat and material waste. A cold saw uses a toothed blade that produces precise, clean cuts with minimal heat, making it ideal for maintaining metal integrity. Your choice depends on balancing speed versus cut quality and the type of metal you are working with.

Abrasive cutoff saw vs cold saw Infographic

libmatt.com

libmatt.com