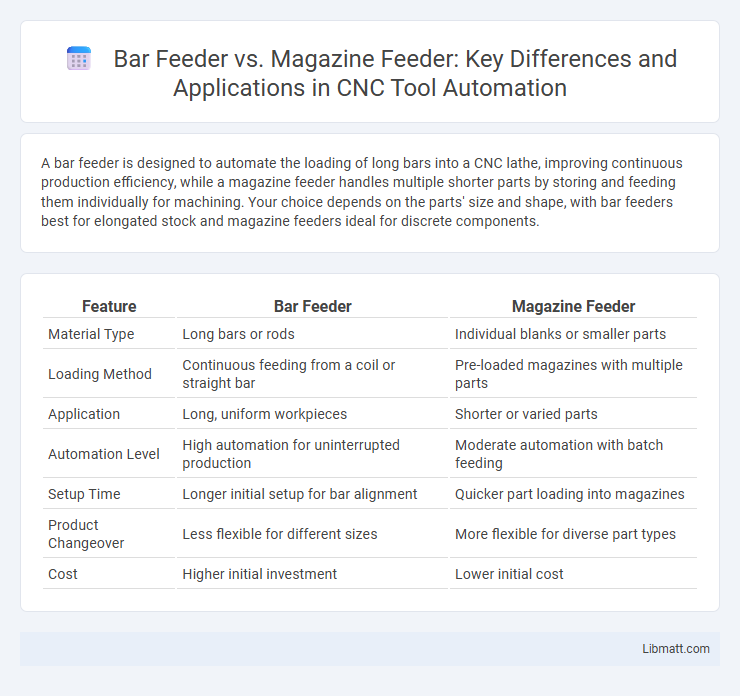

A bar feeder is designed to automate the loading of long bars into a CNC lathe, improving continuous production efficiency, while a magazine feeder handles multiple shorter parts by storing and feeding them individually for machining. Your choice depends on the parts' size and shape, with bar feeders best for elongated stock and magazine feeders ideal for discrete components.

Table of Comparison

| Feature | Bar Feeder | Magazine Feeder |

|---|---|---|

| Material Type | Long bars or rods | Individual blanks or smaller parts |

| Loading Method | Continuous feeding from a coil or straight bar | Pre-loaded magazines with multiple parts |

| Application | Long, uniform workpieces | Shorter or varied parts |

| Automation Level | High automation for uninterrupted production | Moderate automation with batch feeding |

| Setup Time | Longer initial setup for bar alignment | Quicker part loading into magazines |

| Product Changeover | Less flexible for different sizes | More flexible for diverse part types |

| Cost | Higher initial investment | Lower initial cost |

Introduction to Feeder Technologies

Feeder technologies such as bar feeders and magazine feeders are essential for automating CNC machining processes, improving efficiency and reducing manual labor. Bar feeders are designed to continuously supply long bars of raw material into a machine, enabling extended runs with minimal intervention, while magazine feeders hold multiple workpieces in a cartridge for sequential loading, ideal for high-mix, short-run production. Choosing between bar feeders and magazine feeders depends on factors like production volume, material type, and machine compatibility to optimize workflow and minimize downtime.

What is a Bar Feeder?

A Bar Feeder is a mechanical device used in CNC machining to automatically load bar stock into a lathe, enhancing production efficiency by reducing manual intervention. It supports continuous feeding of long bars, enabling high-volume manufacturing with minimal downtime. Compared to magazine feeders, bar feeders excel in handling longer, heavier bars and are ideal for sustained, automated machining processes.

What is a Magazine Feeder?

A magazine feeder is an automated device designed to hold and supply multiple parts or components sequentially to a machine tool, enhancing production efficiency by streamlining the loading process. Unlike bar feeders that handle long, cylindrical stock bars for turning operations, magazine feeders accommodate a variety of individual pieces stored in magazines or trays, ideal for short-run or batch manufacturing. Their versatility in managing different part sizes and shapes makes them essential for high-mix production environments requiring rapid changeovers.

Key Differences Between Bar Feeders and Magazine Feeders

Bar feeders are designed to automate the feeding of long, cylindrical stock materials into CNC lathes, providing continuous, smooth supply for high-volume machining. Magazine feeders handle shorter, bulkier workpieces by organizing multiple parts in a carousel or tray, feeding them one at a time for discrete, varied production runs. The primary differences lie in the type and length of material accommodated, feed mechanism complexity, and suitability for specific machining processes.

Advantages of Bar Feeders

Bar feeders offer significant advantages including continuous feeding of long bar stock into CNC machines, reducing downtime and increasing productivity. Their ability to handle longer bars compared to magazine feeders minimizes the need for frequent reloads, enhancing operational efficiency. You benefit from improved automation and fewer manual interventions, which reduces labor costs and potential errors during machining.

Benefits of Magazine Feeders

Magazine feeders offer enhanced automation by efficiently handling multiple parts, reducing manual loading time, and increasing production throughput in CNC machining. They provide consistent and precise feed rates, improving overall machining accuracy and minimizing downtime. This leads to cost savings and higher operational efficiency in manufacturing processes.

Applications and Suitable Materials

Bar feeders are ideal for feeding long, slender metal bars, such as steel, aluminum, and brass, into CNC lathes for high-volume production in automotive and aerospace industries. Magazine feeders excel in handling short, small-diameter components like screws, pins, and washers, commonly used in electronics and precision manufacturing. Selecting the appropriate feeder depends on material shape, size, and production volume requirements to optimize efficiency and machining accuracy.

Cost Comparison: Bar Feeder vs Magazine Feeder

Bar feeders generally have a higher initial cost compared to magazine feeders due to their complex design and automated feeding capabilities. Magazine feeders offer a more cost-effective solution for short or medium production runs, with lower upfront investment and simpler maintenance requirements. Your choice between the two should consider production volume, budget constraints, and long-term operational efficiency to optimize overall cost-effectiveness.

Maintenance and Operational Considerations

Bar feeders require regular lubrication and alignment checks to ensure smooth material feeding and prevent downtime, while magazine feeders necessitate frequent inspection of the feed mechanism and magazine slots to avoid jamming and misfeeds. Operational efficiency in bar feeders depends heavily on consistent bar straightness and secure clamping, whereas magazine feeders demand careful management of part orientation and magazine capacity for uninterrupted production. Maintenance schedules for both systems should emphasize timely wear part replacement to maintain reliability and optimize machine uptime.

Choosing the Right Feeder for Your CNC Machine

Selecting the appropriate feeder for your CNC machine depends on production volume and material size, with bar feeders best suited for long, continuous round bars to maximize automation and reduce manual loading. Magazine feeders excel in handling multiple short workpieces simultaneously, improving efficiency in batch production and minimizing downtime during tool changes. Understanding your machining requirements and part specifications is essential to optimizing feed rate, minimizing cycle time, and enhancing overall manufacturing productivity.

Bar feeder vs magazine feeder Infographic

libmatt.com

libmatt.com