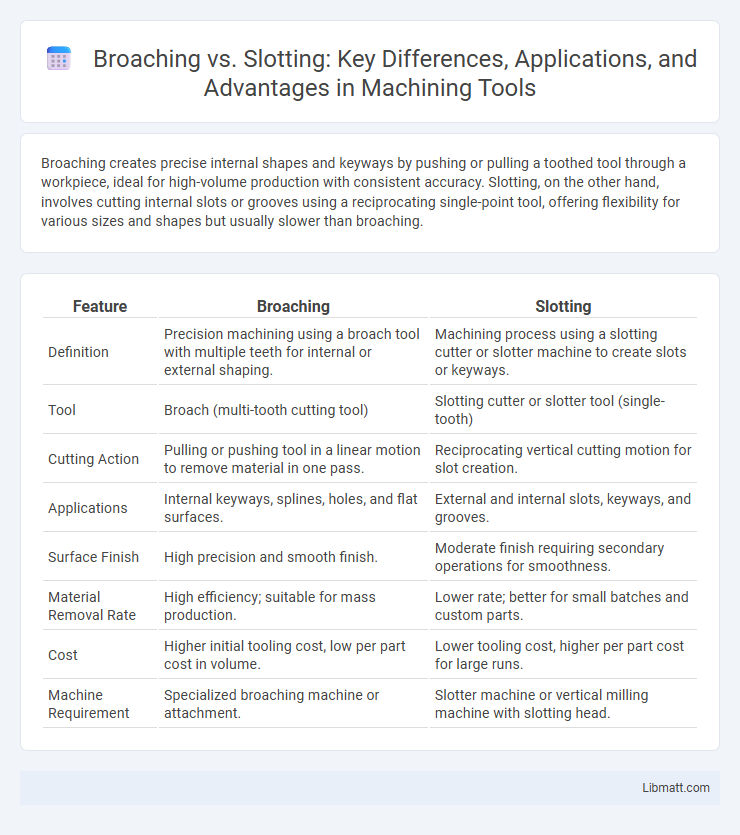

Broaching creates precise internal shapes and keyways by pushing or pulling a toothed tool through a workpiece, ideal for high-volume production with consistent accuracy. Slotting, on the other hand, involves cutting internal slots or grooves using a reciprocating single-point tool, offering flexibility for various sizes and shapes but usually slower than broaching.

Table of Comparison

| Feature | Broaching | Slotting |

|---|---|---|

| Definition | Precision machining using a broach tool with multiple teeth for internal or external shaping. | Machining process using a slotting cutter or slotter machine to create slots or keyways. |

| Tool | Broach (multi-tooth cutting tool) | Slotting cutter or slotter tool (single-tooth) |

| Cutting Action | Pulling or pushing tool in a linear motion to remove material in one pass. | Reciprocating vertical cutting motion for slot creation. |

| Applications | Internal keyways, splines, holes, and flat surfaces. | External and internal slots, keyways, and grooves. |

| Surface Finish | High precision and smooth finish. | Moderate finish requiring secondary operations for smoothness. |

| Material Removal Rate | High efficiency; suitable for mass production. | Lower rate; better for small batches and custom parts. |

| Cost | Higher initial tooling cost, low per part cost in volume. | Lower tooling cost, higher per part cost for large runs. |

| Machine Requirement | Specialized broaching machine or attachment. | Slotter machine or vertical milling machine with slotting head. |

Introduction to Broaching and Slotting

Broaching and slotting are precision machining processes used to create internal or external profiles in metal workpieces. Broaching employs a toothed tool called a broach to remove material in a single pass, ideal for complex shapes and high-volume production. Slotting uses a vertically reciprocating tool to cut slots or grooves, offering versatility for customizable and low-volume operations tailored to your specific needs.

Basic Principles of Broaching

Broaching is a machining process that uses a toothed tool, called a broach, to remove material in a continuous linear motion, producing precise internal or external profiles with high efficiency. The key principle involves gradually increasing the cutting depth of successive teeth, allowing for smooth and accurate cutting of complex shapes, such as keyways or splines. Your choice of broaching or slotting depends on factors like workpiece geometry, desired surface finish, and production volume.

Fundamental Process of Slotting

Slotting is a machining process where a single-point cutting tool moves in a linear or rotary motion to cut internal or external grooves, keyways, or slots in a workpiece. Unlike broaching, which removes material through a multi-toothed tool in a single pass, slotting typically involves repeated cutting strokes to achieve the desired slot depth and shape. This process is essential for precise slot and groove creation in applications such as gear manufacturing and keyway cutting.

Key Differences Between Broaching and Slotting

Broaching uses a multi-toothed tool moving linearly to remove material in a single pass, while slotting employs a single-point cutting tool that moves vertically or horizontally to create slots. Broaching is ideal for producing internal or external shapes with high precision and smooth finishes, whereas slotting is better suited for cutting slots or keyways with greater flexibility but slower material removal rates. Your choice between broaching and slotting depends on the complexity, volume, and accuracy requirements of the machining task.

Typical Applications of Broaching

Broaching is commonly applied in manufacturing to create precise internal shapes such as keyways, splines, and gear profiles in components like automotive parts, aerospace components, and machine tools. Its ability to produce complex, high-tolerance features in a single pass makes it ideal for mass production and intricate metalworking tasks. Common industries utilizing broaching include automotive transmission manufacturing, aircraft engine production, and heavy machinery assembly.

Common Uses of Slotting Machines

Slotting machines are commonly used in machining processes to create internal keyways, slots, and grooves in metal components, particularly in gear manufacturing and engine part production. These machines excel at cutting precise, vertical, and narrow slots that are essential for mechanical assemblies and machinery. Your choice of a slotting machine can significantly improve the accuracy and efficiency of producing complex internal shapes in various industrial applications.

Tooling and Equipment Comparison

Broaching tools feature a series of progressively larger cutting teeth designed to remove material in a single pass, requiring specialized broaching machines with precise linear motion capabilities. Slotting utilizes a single-point cutting tool mounted on a slotting machine that performs vertical reciprocating movements, allowing for versatile shape creation but slower material removal rates. Your choice between broaching and slotting depends on the required precision, production volume, and the specific tooling investment suitable for your machining needs.

Advantages of Broaching vs Slotting

Broaching offers higher precision and smoother surface finishes compared to slotting, making it ideal for producing complex shapes with tight tolerances. The process is faster and more efficient, especially for high-volume production, due to its continuous cutting action. Broaching also reduces tool wear and minimizes manual intervention, resulting in consistent quality and lower operational costs relative to slotting.

Limitations and Drawbacks of Each Method

Broaching faces limitations in handling complex internal shapes and requires custom broach tools, leading to high initial costs and reduced flexibility. Slotting often results in lower surface finish quality and is slower compared to other methods, making it less efficient for large production runs. Your choice depends on balancing precision needs against tool costs and production volume constraints.

Choosing the Right Machining Process

Selecting the appropriate machining process between broaching and slotting depends on factors such as part geometry, production volume, and desired precision. Broaching offers high efficiency for producing complex internal shapes and keyways with superior surface finish, ideal for mass production. Slotting provides flexibility for varied slot shapes and depths, making it suitable for lower volume or prototype work requiring customization.

Broaching vs slotting Infographic

libmatt.com

libmatt.com