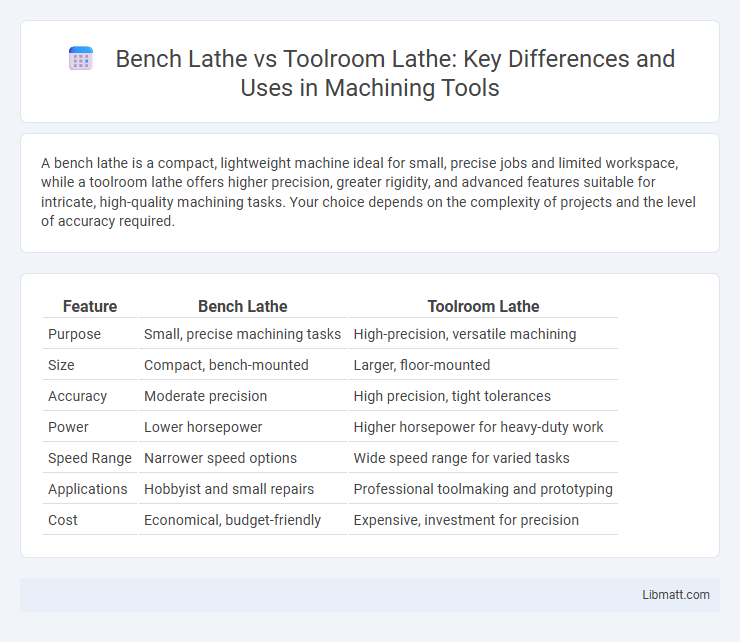

A bench lathe is a compact, lightweight machine ideal for small, precise jobs and limited workspace, while a toolroom lathe offers higher precision, greater rigidity, and advanced features suitable for intricate, high-quality machining tasks. Your choice depends on the complexity of projects and the level of accuracy required.

Table of Comparison

| Feature | Bench Lathe | Toolroom Lathe |

|---|---|---|

| Purpose | Small, precise machining tasks | High-precision, versatile machining |

| Size | Compact, bench-mounted | Larger, floor-mounted |

| Accuracy | Moderate precision | High precision, tight tolerances |

| Power | Lower horsepower | Higher horsepower for heavy-duty work |

| Speed Range | Narrower speed options | Wide speed range for varied tasks |

| Applications | Hobbyist and small repairs | Professional toolmaking and prototyping |

| Cost | Economical, budget-friendly | Expensive, investment for precision |

Introduction to Bench Lathe and Toolroom Lathe

Bench lathes are compact machines designed for small-scale precision tasks, commonly used in workshops for hobbyists and light-duty metalworking. Toolroom lathes offer higher precision and rigidity, equipped with advanced features suitable for machining intricate parts and prototype development in professional settings. Your choice between these machines depends on the required accuracy, complexity of work, and workspace constraints.

Key Differences Between Bench and Toolroom Lathes

Bench lathes are smaller, portable machines designed for light-duty tasks and quick repairs, typically featuring lower horsepower and simpler controls. Toolroom lathes, on the other hand, are precision machines with higher rigidity, accuracy, and advanced features like variable speed control and fine feed adjustments, ideal for detailed, high-precision work. The key differences include size, accuracy, spindle speed options, and intended applications, with toolroom lathes excelling in complex machining operations and bench lathes suited for general-purpose or maintenance uses.

Construction and Design Features

Bench lathes feature compact, lightweight construction with a fixed bed and are designed for small to medium precision tasks, making them suitable for hobbyists or light workshop use. Toolroom lathes have robust, heavy-duty cast iron beds, intricate ways, and precise spindle bearings engineered for high accuracy and repeatability in professional settings. Your choice depends on the required precision and workload, where toolroom lathes excel in stability and fine machining compared to the simpler design of bench lathes.

Size and Space Requirements

Bench lathes are compact machines designed for small-scale projects, making them ideal when working with limited space or a home workshop. Toolroom lathes, on the other hand, require a larger footprint due to their more robust construction and advanced features, suited for detailed and precision work in professional environments. Your choice between these lathes should consider available floor space and the scale of your machining tasks.

Precision and Accuracy Comparison

Bench lathes offer moderate precision suitable for small-scale or hobby projects, while toolroom lathes provide superior accuracy with tighter tolerances for professional-grade machining tasks. Toolroom lathes feature advanced spindle bearings, rigid construction, and fine adjustment capabilities, ensuring consistent repeatability and minimal runout. Choosing a toolroom lathe enhances your ability to achieve highly precise components critical in industries like aerospace and medical device manufacturing.

Typical Applications and Uses

Bench lathes are commonly used for small-scale, precise machining tasks such as hobby projects, prototyping, and light-duty metalworking, offering convenience in workshops with limited space. Toolroom lathes are designed for high-precision, heavy-duty operations in industrial settings, including the production of intricate components, tooling, and fixtures requiring tight tolerances. Both types serve essential roles in manufacturing, with bench lathes excelling in versatility for detailed work and toolroom lathes providing robustness for complex, repetitive tasks.

Versatility and Functionality

Bench lathes offer compact design and ease of use, making them ideal for small-scale projects and precision tasks, while toolroom lathes provide advanced features and higher precision suitable for complex machining operations. Toolroom lathes support a wider range of tooling options and adjustable speed settings, enhancing versatility for intricate workpieces. Bench lathes excel in convenience and portability but lack the extensive functionality and robust construction found in toolroom lathes, which are designed for professional, high-accuracy applications.

Cost and Investment Considerations

Bench lathes typically have a lower initial cost, making them ideal for hobbyists and small workshops with limited budgets. Toolroom lathes involve a higher investment due to their precision engineering, enhanced rigidity, and advanced features suited for intricate machining tasks. Budget allocation should consider long-term needs, as toolroom lathes can deliver superior accuracy and durability that justify the upfront expense in professional or high-precision environments.

Maintenance and Ease of Use

Bench lathes require minimal maintenance due to their simple design, making them ideal for hobbyists and light-duty tasks, while toolroom lathes demand more frequent upkeep to ensure precision and smooth operation in high-accuracy applications. The ease of use in bench lathes stems from their straightforward controls and compact size, whereas toolroom lathes feature advanced settings and adjustments that require skilled operators but enable more complex machining. Proper lubrication and timely parts replacement are crucial for both types to maintain optimal performance and extend machine lifespan.

Choosing the Right Lathe for Your Workshop

Bench lathes are compact, ideal for small-scale projects, precision work, and hobbyists due to their portability and ease of use. Toolroom lathes offer higher precision, enhanced rigidity, and versatility, making them suitable for professional machining, complex tasks, and fine tolerance requirements. Selecting the right lathe depends on the workshop's production needs, available space, and the level of accuracy required for the intended applications.

Bench lathe vs toolroom lathe Infographic

libmatt.com

libmatt.com