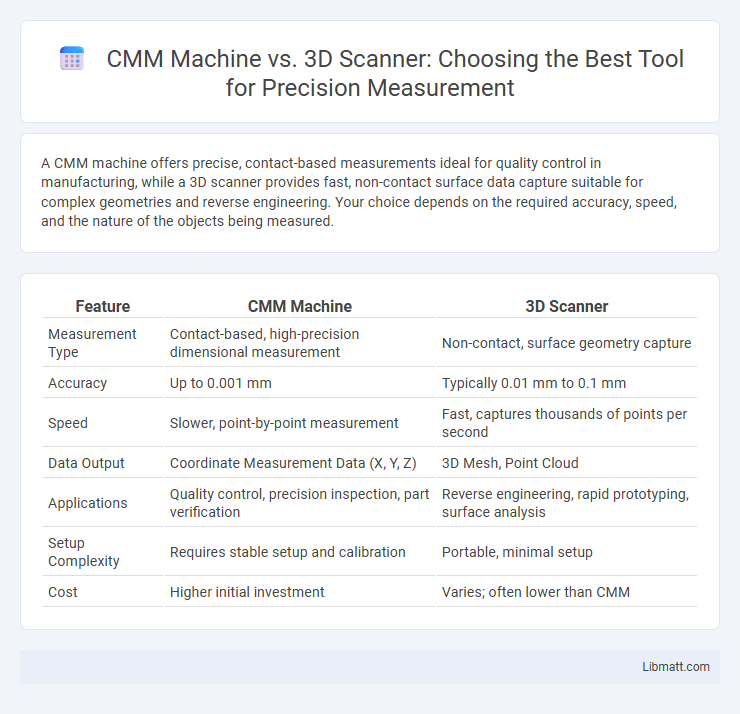

A CMM machine offers precise, contact-based measurements ideal for quality control in manufacturing, while a 3D scanner provides fast, non-contact surface data capture suitable for complex geometries and reverse engineering. Your choice depends on the required accuracy, speed, and the nature of the objects being measured.

Table of Comparison

| Feature | CMM Machine | 3D Scanner |

|---|---|---|

| Measurement Type | Contact-based, high-precision dimensional measurement | Non-contact, surface geometry capture |

| Accuracy | Up to 0.001 mm | Typically 0.01 mm to 0.1 mm |

| Speed | Slower, point-by-point measurement | Fast, captures thousands of points per second |

| Data Output | Coordinate Measurement Data (X, Y, Z) | 3D Mesh, Point Cloud |

| Applications | Quality control, precision inspection, part verification | Reverse engineering, rapid prototyping, surface analysis |

| Setup Complexity | Requires stable setup and calibration | Portable, minimal setup |

| Cost | Higher initial investment | Varies; often lower than CMM |

Introduction to CMM Machines and 3D Scanners

CMM machines use tactile probes to measure physical geometries with high precision, capturing exact dimensions by contacting the object's surface. 3D scanners employ non-contact technologies like laser or structured light to rapidly capture detailed surface data as a point cloud, enabling complex shape analysis. Both tools serve critical roles in quality control and reverse engineering but differ substantially in measurement approach and data output types.

Working Principles: CMM vs 3D Scanner

Coordinate Measuring Machines (CMM) operate by physically touching the object with a probe to record precise dimensions through tactile sensing, ensuring high accuracy in measurement. 3D scanners use non-contact methods such as laser, structured light, or photogrammetry to capture millions of data points rapidly for creating detailed digital models. Your choice depends on whether tactile accuracy or speed and surface complexity in measurement is more critical for your application.

Accuracy and Precision Comparison

CMM machines typically offer higher accuracy and precision, often achieving tolerances within microns due to their physical probing mechanisms and rigid construction. In contrast, 3D scanners rely on optical technology, which can result in slightly lower accuracy, usually in the range of tens of microns, influenced by surface reflectivity and environmental conditions. The choice between CMM and 3D scanning depends on the required measurement fidelity, with CMMs preferred for precision-critical tasks and 3D scanners favored for rapid, non-contact data acquisition.

Speed and Efficiency

CMM machines provide precise measurements but operate at slower speeds due to their tactile probing methods, making them less efficient for large or complex parts. 3D scanners capture entire surfaces rapidly with non-contact technology, dramatically improving speed and workflow efficiency for detailed inspections. Your choice hinges on balancing the need for accuracy with the demand for fast data collection in quality control processes.

Types of Measured Components

CMM machines excel in measuring geometric features of rigid components such as machined parts, engine blocks, and aerospace assemblies with high precision. 3D scanners are ideal for capturing complex surfaces and freeform shapes, including sculptures, automotive bodies, and anatomical models. Both tools complement each other by addressing different types of components in quality control and reverse engineering workflows.

Ease of Use and Training Requirements

CMM machines typically require specialized training due to their complex software interfaces and precise operation protocols, making them less intuitive for beginners. 3D scanners offer a more user-friendly experience with simpler workflows and quicker setup, reducing the learning curve for new users. Ease of use and minimal training requirements make 3D scanners ideal for rapid inspection and flexible applications in various industries.

Data Output and Software Compatibility

CMM machines generate highly precise coordinate data points ideal for detailed geometric measurements, outputting formats such as IGES, STEP, or DMIS that integrate seamlessly with metrology software like PC-DMIS or Calypso. In contrast, 3D scanners produce dense cloud points or mesh data formats like STL, OBJ, or PLY, which are commonly compatible with reverse engineering and CAD software including Geomagic and MeshLab. Your choice depends on whether you require dimensional accuracy for inspection (CMM) or versatile 3D modeling and surface analysis (scanner) supported by respective software ecosystems.

Cost Analysis and Investment

Coordinate Measuring Machines (CMM) typically involve higher initial investment costs, including hardware, software, and skilled operator training, with prices ranging from $50,000 to over $200,000 depending on precision and size. 3D scanners generally present a lower upfront cost, starting from $10,000 for basic models to around $100,000 for advanced systems, offering faster data acquisition and flexibility with less operator expertise required. Long-term investment considerations favor 3D scanners for rapid prototyping and reverse engineering, while CMMs remain the preferred choice for high-precision validation in manufacturing environments.

Industry Applications: CMM vs 3D Scanner

CMM machines excel in precision measurement for aerospace, automotive, and manufacturing industries where strict dimensional tolerances are crucial. 3D scanners are widely used in reverse engineering, quality inspection, and rapid prototyping across sectors like healthcare, heritage preservation, and consumer goods. Your choice depends on whether you prioritize exact dimensional accuracy (CMM) or speed and detailed surface capture (3D scanning).

Choosing the Right Measurement Solution

Choosing between a CMM machine and a 3D scanner depends on your specific measurement needs, accuracy requirements, and budget constraints. CMM machines provide highly precise contact measurements ideal for detailed inspection of complex geometries, while 3D scanners offer faster, non-contact data acquisition suited for capturing surface details and reverse engineering. Assess your project scope and desired output quality to select the measurement solution that best aligns with your production goals and quality standards.

CMM machine vs 3D scanner Infographic

libmatt.com

libmatt.com