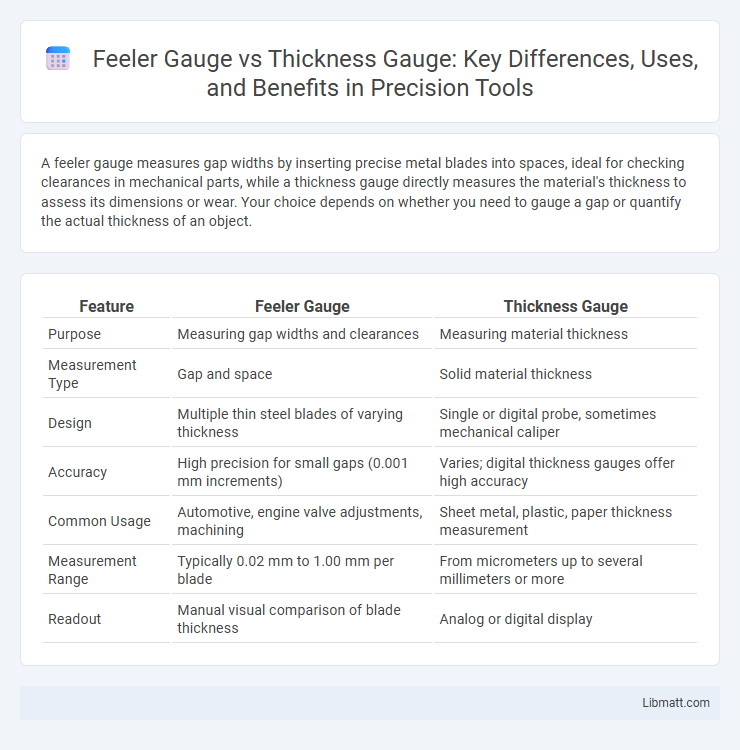

A feeler gauge measures gap widths by inserting precise metal blades into spaces, ideal for checking clearances in mechanical parts, while a thickness gauge directly measures the material's thickness to assess its dimensions or wear. Your choice depends on whether you need to gauge a gap or quantify the actual thickness of an object.

Table of Comparison

| Feature | Feeler Gauge | Thickness Gauge |

|---|---|---|

| Purpose | Measuring gap widths and clearances | Measuring material thickness |

| Measurement Type | Gap and space | Solid material thickness |

| Design | Multiple thin steel blades of varying thickness | Single or digital probe, sometimes mechanical caliper |

| Accuracy | High precision for small gaps (0.001 mm increments) | Varies; digital thickness gauges offer high accuracy |

| Common Usage | Automotive, engine valve adjustments, machining | Sheet metal, plastic, paper thickness measurement |

| Measurement Range | Typically 0.02 mm to 1.00 mm per blade | From micrometers up to several millimeters or more |

| Readout | Manual visual comparison of blade thickness | Analog or digital display |

Introduction to Feeler Gauge and Thickness Gauge

Feeler gauges are precision tools composed of multiple thin metal blades with varying thicknesses for measuring gap widths or clearances in mechanical components. Thickness gauges, also known as thickness micrometers or dial thickness gauges, provide accurate measurements of material thickness using a dial or digital readout. Both tools are essential in engineering and manufacturing for ensuring precise dimensional checks but serve distinct functions based on application requirements.

Definition and Purpose of Feeler Gauge

A feeler gauge is a precision measuring tool consisting of a set of thin metal blades of varying thicknesses used to measure gap widths or clearances between two parts. Its primary purpose is to ensure accurate spacing in mechanical components such as engine parts or machinery to maintain optimal performance and prevent wear. Unlike thickness gauges that measure material thickness, feeler gauges focus specifically on verifying gap sizes for assembly and maintenance tasks.

Definition and Purpose of Thickness Gauge

A thickness gauge is a precision tool designed to measure the thickness of various materials such as metals, plastics, and coatings, providing accurate dimensional data critical for quality control and manufacturing processes. Unlike feeler gauges used primarily for measuring gap clearances, thickness gauges employ techniques like ultrasonic or mechanical methods to quantify material thickness with high resolution. This ensures adherence to specifications and helps detect material inconsistencies or wear in industrial applications.

Key Differences Between Feeler Gauge and Thickness Gauge

Feeler gauges measure gap widths and clearance with precision using thin metal strips, while thickness gauges directly measure the material thickness of objects. The feeler gauge is ideal for automotive or mechanical applications requiring gap assessment, whereas thickness gauges serve industries focusing on material uniformity such as metal, plastic, or paper production. Your choice depends on whether you need to evaluate space between parts or the overall thickness of a single material.

Applications of Feeler Gauges in Industry

Feeler gauges are widely used in automotive, manufacturing, and mechanical industries to measure gap widths and ensure precise tolerances between components such as spark plugs, valve clearances, and bearing gaps. Their ability to provide accurate thickness measurements in tight spaces makes them essential for quality control and maintenance tasks. Unlike thickness gauges, which measure material thickness, feeler gauges excel in assessing clearances critical for machine performance and safety.

Applications of Thickness Gauges in Industry

Thickness gauges are extensively used in industries such as automotive, aerospace, and manufacturing for measuring material thickness with high precision. They help ensure quality control by detecting variations in metal sheets, coatings, and plastic components, preventing structural failures and maintaining product standards. Your ability to accurately measure and verify thickness supports efficient production processes and compliance with industry specifications.

Materials and Design Comparison

Feeler gauges are typically crafted from high-grade stainless steel strips, designed to flex and fit into narrow gaps for precise measurement of clearance or gap widths, whereas thickness gauges often utilize rigid, flat blades made from steel or plastic, tailored for measuring the overall thickness of materials like sheets or films. The design of feeler gauges emphasizes flexibility and graduated increments, allowing multiple leaf blades to stack for cumulative thickness checks, while thickness gauges prioritize a solid, uniform thickness measurement surface for durability and consistent readings. Material selection in feeler gauges aims for corrosion resistance and accuracy in thin gap detection, contrasting with the focus on hardness and resistance to wear found in thickness gauge blades for tougher material evaluations.

Measurement Accuracy and Precision

Feeler gauges provide high precision in measuring small gaps and clearances, typically within 0.001 mm or 0.0001 inches, making them ideal for tight tolerance inspections. Thickness gauges, including electronic and mechanical types, offer accurate measurements of material thickness but may vary in precision depending on the technology used, often ranging from 0.01 mm to 0.001 mm accuracy. Choosing between the two depends on the specific application requirements, with feeler gauges excelling in precise clearance measurements and thickness gauges suited for broader material assessments.

Pros and Cons of Feeler Gauges

Feeler gauges offer precise measurement of small gaps and clearances, making them ideal for automotive and engineering tasks where accuracy is critical. They provide high accuracy and simplicity, but their limited measurement range and vulnerability to dirt or wear can reduce reliability over time. Your choice depends on whether you need fine tolerance measurements or a broader thickness range typically covered by thickness gauges.

Pros and Cons of Thickness Gauges

Thickness gauges offer precise measurement of material thickness, making them ideal for quality control in manufacturing and inspection processes. However, they may lack the versatility of feeler gauges, which excel in measuring small gaps and clearances with flexibility. Your choice depends on whether you need exact thickness readings or adaptable gap measurement.

Feeler gauge vs thickness gauge Infographic

libmatt.com

libmatt.com