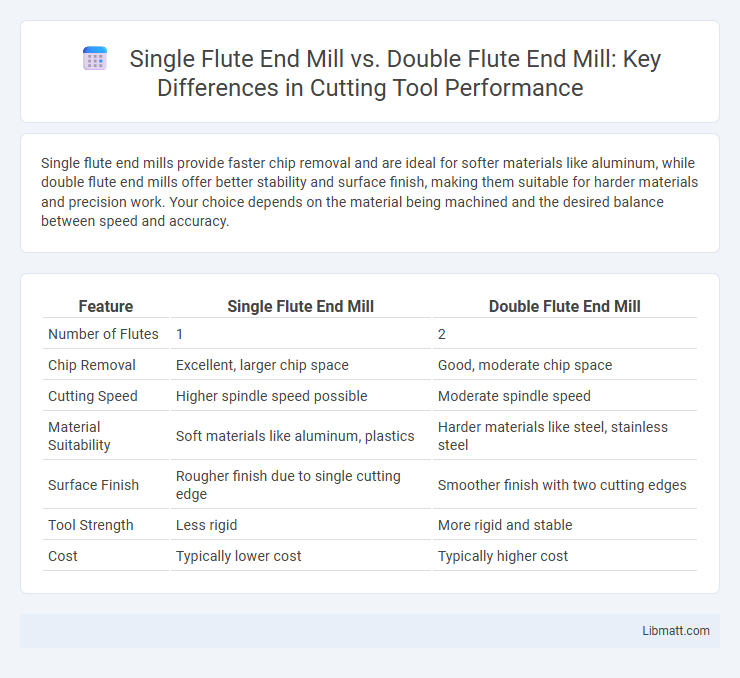

Single flute end mills provide faster chip removal and are ideal for softer materials like aluminum, while double flute end mills offer better stability and surface finish, making them suitable for harder materials and precision work. Your choice depends on the material being machined and the desired balance between speed and accuracy.

Table of Comparison

| Feature | Single Flute End Mill | Double Flute End Mill |

|---|---|---|

| Number of Flutes | 1 | 2 |

| Chip Removal | Excellent, larger chip space | Good, moderate chip space |

| Cutting Speed | Higher spindle speed possible | Moderate spindle speed |

| Material Suitability | Soft materials like aluminum, plastics | Harder materials like steel, stainless steel |

| Surface Finish | Rougher finish due to single cutting edge | Smoother finish with two cutting edges |

| Tool Strength | Less rigid | More rigid and stable |

| Cost | Typically lower cost | Typically higher cost |

Introduction to End Mills

Single flute end mills offer increased chip clearance and faster material removal, making them ideal for softer materials like plastics and aluminum. Double flute end mills provide a balance between cutting speed and surface finish, suited for harder materials such as steel and stainless steel. Choosing between single flute and double flute end mills depends on factors like material type, machining speed, and desired finish quality.

Understanding Flute Counts in End Mills

Single flute end mills offer higher chip clearance and are ideal for aggressive material removal in softer materials like aluminum. Double flute end mills balance chip evacuation and surface finish, making them versatile for harder materials such as steel. Choosing the right flute count optimizes cutting efficiency by managing chip load, heat dissipation, and tool stability.

What is a Single Flute End Mill?

A single flute end mill features one cutting edge designed to provide maximum chip clearance and efficient material removal, making it ideal for high-speed cutting of softer materials like aluminum and plastics. Its reduced number of flutes allows for faster feed rates and lower heat buildup, enhancing tool life during aggressive machining. Understanding the capabilities of your single flute end mill helps optimize cutting performance and surface finish in specialized applications.

Key Features of Double Flute End Mills

Double flute end mills feature two cutting edges designed for efficient chip evacuation and smooth surface finishes, making them ideal for slotting and side milling in softer materials like aluminum. Their geometry allows for higher feed rates and better control over tool deflection, enhancing precision in intricate machining tasks. This design also reduces vibration and heat buildup, prolonging tool life and maintaining consistent performance during high-speed operations.

Material Removal Rate: Single vs Double Flute

Single flute end mills excel in high material removal rates on softer materials due to their larger flute volume, enabling efficient chip evacuation and reduced heat buildup. Double flute end mills provide a balanced approach with moderate material removal rates, offering stability and smoother finishes on harder materials. Your choice depends on the specific machining task, prioritizing either rapid material removal or surface quality.

Chip Evacuation and Surface Finish Comparison

Single flute end mills provide superior chip evacuation due to their larger flute space, making them ideal for softer materials and high-speed cutting where efficient debris removal prevents clogging. Double flute end mills offer a better surface finish, as their increased cutting edges deliver smoother cuts and finer detail, especially in harder materials. The choice between single and double flute end mills balances chip evacuation efficiency and surface finish quality based on the material type and machining requirements.

Best Applications for Single Flute End Mills

Single flute end mills excel in high-speed cutting and are ideal for soft materials like aluminum, plastics, and composites due to their efficient chip evacuation and reduced heat buildup. Their single cutting edge allows for faster material removal rates in applications requiring aggressive cuts and minimal tool engagement. For Your machining tasks involving non-ferrous metals or where surface finish is less critical, single flute end mills provide optimal performance and extended tool life.

Optimal Uses for Double Flute End Mills

Double flute end mills excel in cutting softer materials like aluminum and plastics, offering faster feed rates and improved chip evacuation compared to multiple-flute tools. Their design provides a balance between material removal rate and surface finish, making them ideal for semi-finishing operations. Optimal uses include slotting, profiling, and plunge cutting where high-speed performance and efficient chip removal are critical.

Choosing the Right End Mill for Your Project

Selecting the right end mill depends on factors such as material type, cut quality, and feed rate requirements, with single flute end mills offering optimized chip clearance and higher feed rates ideal for soft materials like aluminum and plastics. Double flute end mills provide smoother finishes and better rigidity, making them suitable for harder materials or detailed contouring work. Proper tool selection enhances machining efficiency, surface finish, and tool life by matching flute design to project specifications and material characteristics.

Conclusion: Which Flute Count Is Better?

Single flute end mills excel in high-speed machining of soft materials, offering superior chip clearance and reduced heat build-up, while double flute end mills provide enhanced stability and are ideal for harder materials with moderate feed rates. The choice depends on the application: single flute is better for aluminum and plastics requiring fast material removal, whereas double flute is preferred for steel and general-purpose milling needing precision and surface finish. Ultimately, selecting the optimal flute count hinges on balancing chip evacuation, cutting speed, and material hardness for improved tool life and machining efficiency.

Single flute end mill vs double flute end mill Infographic

libmatt.com

libmatt.com