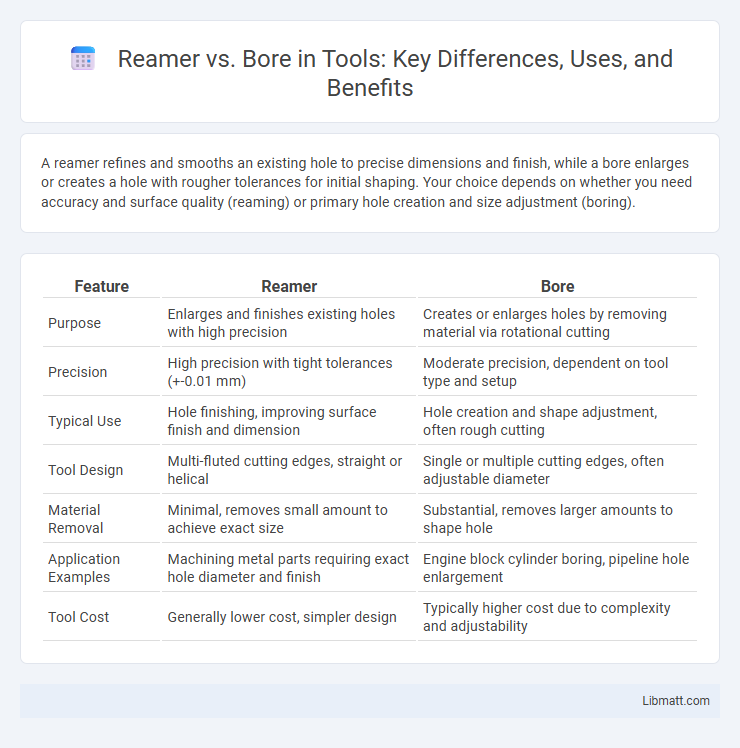

A reamer refines and smooths an existing hole to precise dimensions and finish, while a bore enlarges or creates a hole with rougher tolerances for initial shaping. Your choice depends on whether you need accuracy and surface quality (reaming) or primary hole creation and size adjustment (boring).

Table of Comparison

| Feature | Reamer | Bore |

|---|---|---|

| Purpose | Enlarges and finishes existing holes with high precision | Creates or enlarges holes by removing material via rotational cutting |

| Precision | High precision with tight tolerances (+-0.01 mm) | Moderate precision, dependent on tool type and setup |

| Typical Use | Hole finishing, improving surface finish and dimension | Hole creation and shape adjustment, often rough cutting |

| Tool Design | Multi-fluted cutting edges, straight or helical | Single or multiple cutting edges, often adjustable diameter |

| Material Removal | Minimal, removes small amount to achieve exact size | Substantial, removes larger amounts to shape hole |

| Application Examples | Machining metal parts requiring exact hole diameter and finish | Engine block cylinder boring, pipeline hole enlargement |

| Tool Cost | Generally lower cost, simpler design | Typically higher cost due to complexity and adjustability |

Introduction to Reamer and Bore

A reamer is a precision cutting tool designed to enlarge and finish an existing hole to exact dimensions with smooth surface finishes. A bore refers to the internal diameter of a hole or cylinder, often machined to specific tolerances for components like engine cylinders or hydraulic cylinders. Understanding the differences between reaming and boring processes helps ensure Your machining operations achieve the required accuracy and surface quality.

Definition and Function of Reaming

Reaming is a precise machining process designed to slightly enlarge and finish an existing hole with high accuracy, improving its surface finish and dimensional consistency. A reamer, typically a rotary cutting tool with multiple cutting edges, is used to achieve tight tolerances and smooth holes that drilling alone cannot provide. You can rely on reaming to refine holes for better fit and alignment in assemblies where exact hole diameter is critical.

Understanding Boring: Purpose and Process

Boring is a precision machining process used to enlarge and finish existing holes with high accuracy, often improving surface finish and dimensional tolerance beyond initial drilling capabilities. A reamer, by contrast, is a rotary cutting tool designed specifically to smooth or slightly enlarge holes to exact dimensions with a fine surface finish. Understanding the distinction between boring and reaming is crucial for selecting the right method based on the required hole size, tolerance, and finish quality in manufacturing or metalworking applications.

Key Differences Between Reaming and Boring

Reaming enhances hole accuracy and surface finish by removing minimal material with a multi-edged cutting tool, while boring enlarges existing holes with a single-point cutting tool, typically allowing greater dimensional adjustments. Reaming focuses on achieving precise diameters and better surface quality, whereas boring is used for correcting hole geometry or increasing size beyond initial drilling capabilities. Your choice depends on tolerance requirements and the hole's initial size, with reaming suited for fine finishing and boring ideal for significant hole enlargement.

Applications of Reaming in Industry

Reaming is widely used in industries such as aerospace, automotive, and manufacturing to achieve precise hole sizing and improved surface finish. It corrects the alignment and geometry of drilled holes for better fitment of components, ensuring high tolerance and reducing wear in mechanical assemblies. When you require smooth, accurate holes for shafts, fasteners, or hydraulic components, reaming provides superior dimensional control compared to boring.

Typical Uses of Boring Operations

Boring operations are primarily used to enlarge existing holes with high precision, typically in engine cylinders, machine components, and aerospace parts requiring tight tolerances. Reaming is ideal for finishing holes to smooth and accurate dimensions after drilling or boring, often ensuring surface finish and exact size in metalworking and manufacturing processes. Boring is preferred when critical alignment, diameter accuracy, and concentricity are necessary in large or deep holes.

Tool Design: Reamers vs. Boring Bars

Reamers feature multiple straight or helical cutting edges arranged around a solid cylindrical body designed for precise hole sizing and surface finish improvement. Boring bars consist of a single cutting tool mounted on a rigid bar, allowing for adjustable cutting depth and diameter enlargement within existing holes. The design of reamers emphasizes dimensional accuracy and smooth finishes, whereas boring bars offer flexibility for custom diameter adjustments and internal contour machining.

Precision and Tolerance in Reaming and Boring

Reaming offers higher precision and tighter tolerances compared to boring, typically achieving surface finishes within 0.002 mm. Boring is ideal for enlarging holes with looser tolerances around 0.01 mm but excels in correcting hole alignment and geometry. Your choice between reaming and boring depends on the required accuracy and surface finish quality for your machining project.

Pros and Cons: Reamer vs. Bore

Reamers provide high precision and smooth surface finishes ideal for fine tuning hole diameters, but can be slower and more expensive than boring. Boring offers greater flexibility for enlarging existing holes with improved accuracy over drilling, yet it may result in rougher finishes and requires more complex machinery. Choosing between reaming and boring depends on the desired tolerance, surface quality, and production speed for specific machining applications.

Choosing the Right Method for Your Project

Selecting between reaming and boring depends on the precision and finish required for your project. Reamers offer superior accuracy for finishing pre-drilled holes with tight tolerances, ideal for applications demanding smooth surfaces and exact diameters. Boring is better suited for enlarging existing holes and correcting misaligned bores, providing flexibility for varied sizes and depths in complex machining tasks.

Reamer vs bore Infographic

libmatt.com

libmatt.com