A centering bit is designed to create a precise pilot hole that guides a drill or other cutting tool, ensuring accurate positioning and reducing bit wander. Your choice between a centering bit and a spotting drill depends on the material and application, as spotting drills are primarily used to create shallow, accurate starting points for larger drill bits to prevent walking on hard surfaces.

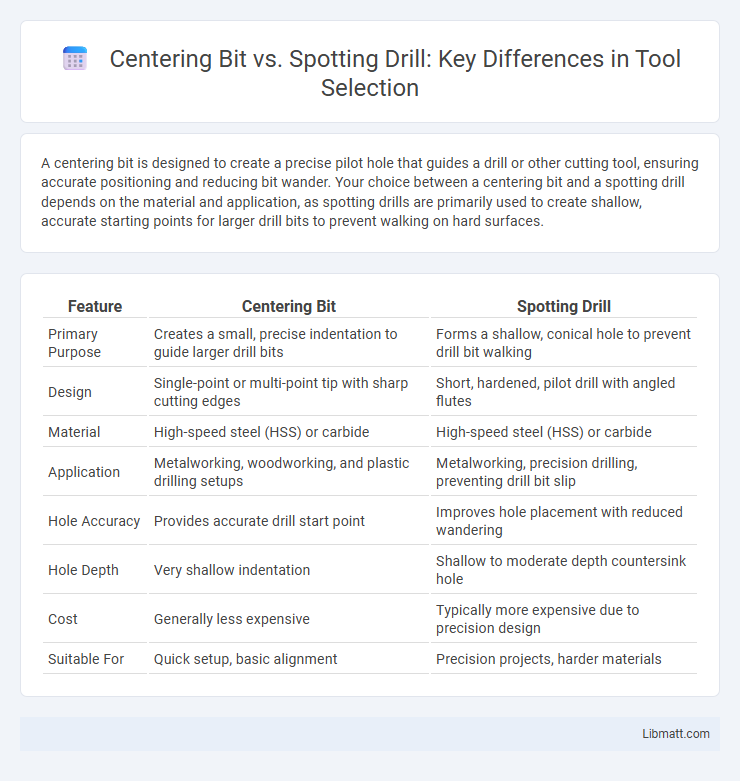

Table of Comparison

| Feature | Centering Bit | Spotting Drill |

|---|---|---|

| Primary Purpose | Creates a small, precise indentation to guide larger drill bits | Forms a shallow, conical hole to prevent drill bit walking |

| Design | Single-point or multi-point tip with sharp cutting edges | Short, hardened, pilot drill with angled flutes |

| Material | High-speed steel (HSS) or carbide | High-speed steel (HSS) or carbide |

| Application | Metalworking, woodworking, and plastic drilling setups | Metalworking, precision drilling, preventing drill bit slip |

| Hole Accuracy | Provides accurate drill start point | Improves hole placement with reduced wandering |

| Hole Depth | Very shallow indentation | Shallow to moderate depth countersink hole |

| Cost | Generally less expensive | Typically more expensive due to precision design |

| Suitable For | Quick setup, basic alignment | Precision projects, harder materials |

Overview: Centering Bit vs Spotting Drill

A centering bit is designed to create a precise starting point for drill bits by producing a small, accurate pilot hole that guides the main drilling operation. Spotting drills are specifically engineered to establish an exact spot with a slight countersink, preventing drill wandering and improving hole accuracy. Compared to centering bits, spotting drills offer enhanced stability and better alignment for subsequent drilling tasks in metalworking and machining applications.

What is a Centering Bit?

A Centering Bit is a precision drill tool designed to create an accurate pilot hole for subsequent drilling, ensuring exact positioning and preventing bit wander. Unlike a spotting drill, which primarily marks the surface for the main drill, the centering bit forms a small, deep, and precise hole that guides larger drill bits. Using a centering bit in your workflow enhances drilling accuracy and improves the quality of the final hole alignment.

What is a Spotting Drill?

A spotting drill is a precision tool used in metalworking to create a small, accurate indentation on a workpiece, guiding the drill bit for exact hole placement and preventing bit wandering. Unlike a centering bit, which combines spot drilling and initial hole cutting, a spotting drill concentrates solely on marking the spot with a short, stiff tip that ensures accuracy. Your machining process benefits from the spotting drill's ability to enhance hole alignment and reduce errors in subsequent drilling steps.

Key Differences between Centering Bits and Spotting Drills

Centering bits create a precise starter hole by removing material to guide larger drill bits, ensuring accuracy and preventing bit wandering. Spotting drills produce a shallow dimple on the material's surface, serving as a visual guide and stabilizing point for the subsequent drilling process. Your choice impacts drilling precision, with centering bits primarily used for accuracy and spotting drills for initial hole placement.

Applications of Centering Bits

Centering bits are primarily used to create a precise starting point for drill bits, ensuring accurate hole placement and minimizing drill bit wandering on materials like wood, metal, or plastic. Their design allows for deeper penetration into the surface to guide subsequent drilling operations, which is especially valuable in woodworking, metal fabrication, and automotive industries. Unlike spotting drills that create shallow guide marks, centering bits establish a defined indentation to improve drilling accuracy and tool stability.

Applications of Spotting Drills

Spotting drills are crucial in diving and gymnastics for safely learning and perfecting complex maneuvers by providing controlled assistance and reducing injury risk. They help athletes develop muscle memory, correct form, and confidence before performing fully independent skills in competitive or training settings. Unlike centering bits used in machining, spotting drills emphasize skill acquisition and injury prevention in sports contexts.

Accuracy and Precision Comparison

Centering bits provide optimal accuracy for preparing pilot holes, ensuring precise alignment for subsequent drilling tasks, while spotting drills excel at creating small, shallow guide marks that reduce bit wander and improve surface precision. In terms of precision, centering bits deliver consistent depth and diameter control due to their conical tips, whereas spotting drills enhance positional precision by accurately marking the drilling spot to prevent slippage. The choice between the two tools depends on the required accuracy in initial hole positioning versus the precision of entry point creation on the workpiece surface.

Material Compatibility and Versatility

Centering bits excel in versatility by efficiently creating precise starter holes in a wide range of materials including wood, metal, and plastic, ensuring compatibility with various drilling tasks. Spotting drills offer superior accuracy and reduced walking in harder materials like stainless steel and hardened alloys, making them ideal for precision machining where exact hole placement is critical. Your choice depends on balancing material compatibility and the desired level of accuracy for the specific drilling application.

Choosing the Right Tool: Centering Bit or Spotting Drill

Choosing between a centering bit and a spotting drill depends on the precision and application requirements in metalworking. A centering bit is ideal for creating shallow, precise starter holes that guide larger drill bits, ensuring accurate hole placement and reducing bit walking. In contrast, a spotting drill produces a small dimple on the workpiece surface to improve the alignment for subsequent drilling, especially useful for tougher materials and preventing off-center holes.

Tips for Effective Use and Maintenance

Centering bits require steady pressure and slow feed rates to create accurate starter holes, while spotting drills benefit from shorter, controlled plunges to establish precise drill location. Regular sharpening and proper lubrication extend the lifespan of both tools, ensuring clean cuts and reducing heat buildup during use. Storing them in protective holders prevents damage to the cutting edges, maintaining optimal performance for repeated drilling tasks.

Centering bit vs spotting drill Infographic

libmatt.com

libmatt.com