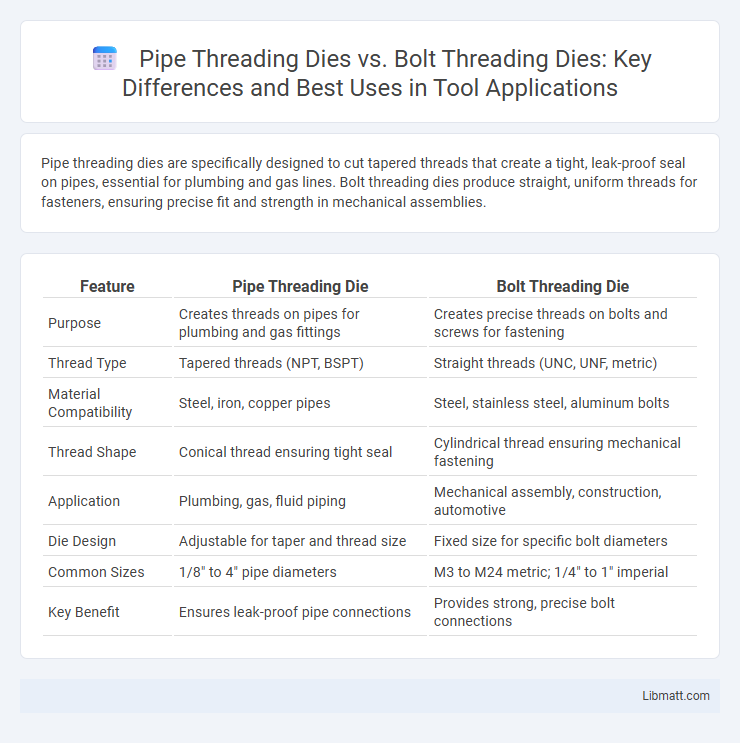

Pipe threading dies are specifically designed to cut tapered threads that create a tight, leak-proof seal on pipes, essential for plumbing and gas lines. Bolt threading dies produce straight, uniform threads for fasteners, ensuring precise fit and strength in mechanical assemblies.

Table of Comparison

| Feature | Pipe Threading Die | Bolt Threading Die |

|---|---|---|

| Purpose | Creates threads on pipes for plumbing and gas fittings | Creates precise threads on bolts and screws for fastening |

| Thread Type | Tapered threads (NPT, BSPT) | Straight threads (UNC, UNF, metric) |

| Material Compatibility | Steel, iron, copper pipes | Steel, stainless steel, aluminum bolts |

| Thread Shape | Conical thread ensuring tight seal | Cylindrical thread ensuring mechanical fastening |

| Application | Plumbing, gas, fluid piping | Mechanical assembly, construction, automotive |

| Die Design | Adjustable for taper and thread size | Fixed size for specific bolt diameters |

| Common Sizes | 1/8" to 4" pipe diameters | M3 to M24 metric; 1/4" to 1" imperial |

| Key Benefit | Ensures leak-proof pipe connections | Provides strong, precise bolt connections |

Introduction to Threading Dies

Threading dies are essential tools for creating precise screw threads on rods or pipes, with pipe threading dies specifically designed to cut tapered threads for sealing pipes in plumbing and gas fittings. Bolt threading dies, on the other hand, produce straight threads suitable for fastening bolts and screws in mechanical assemblies. The fundamental difference lies in the thread profile and application, where pipe dies focus on fluid-tight connections while bolt dies emphasize mechanical strength and fit.

What is a Pipe Threading Die?

A pipe threading die is a specialized tool designed to cut threads on the outside of pipes, enabling secure connections in plumbing and industrial piping systems. Unlike bolt threading dies, which create standardized threads for fasteners, pipe threading dies produce tapered threads that ensure a tight, leak-proof seal when pipes are joined. These dies are essential for fabricating and repairing threaded pipe joints in applications requiring fluid or gas transport.

What is a Bolt Threading Die?

A bolt threading die is a specialized tool designed to cut external threads on bolts, enabling secure fastening in mechanical assemblies. Unlike pipe threading dies used for creating tapered threads on pipes, bolt threading dies produce precise, uniform threads on cylindrical rods with standard pitches and diameters. These tools are essential in manufacturing and repair work where custom-sized bolts are required for specific applications.

Key Differences Between Pipe and Bolt Threading Dies

Pipe threading dies create tapered threads designed to form leak-tight seals in plumbing and gas lines, whereas bolt threading dies produce straight, uniform threads for fastening applications. The geometry of pipe dies accommodates sealing with pipe compounds, while bolt dies prioritize precision and strength for secure mechanical joints. Material hardness and die construction also differ, with pipe dies typically made for softer metals and bolt dies engineered for a variety of materials including hardened steel.

Material Compatibility: Pipe vs Bolt Dies

Pipe threading dies are specifically designed to cut threads on softer materials like steel pipes, galvanized pipes, and brass, ensuring a tight seal for plumbing or gas applications. Bolt threading dies, on the other hand, are optimized for harder metals such as stainless steel or hardened bolts, providing precise external threads for fastening purposes. Your choice between pipe and bolt dies should align with the material you are working on to achieve durable and accurate threading results.

Thread Standards for Pipes and Bolts

Pipe threading dies follow specific thread standards such as NPT (National Pipe Thread) or BSP (British Standard Pipe) designed for creating tapered threads that ensure a tight seal in plumbing and gas systems. Bolt threading dies adhere to standards like UNC (Unified National Coarse), UNF (Unified National Fine), or metric ISO threads, optimized for precise bolt fit and structural integrity. Understanding these distinct thread standards is crucial for your project to ensure compatibility and proper fastening or sealing.

Applications: When to Use Each Die

Pipe threading dies are primarily used for creating tapered threads on pipes, essential for plumbing and gas line installations to ensure leak-proof seals. Bolt threading dies create straight threads on rods or bolts, suitable for fastening applications where precision and uniformity are critical. Your choice depends on whether the project requires joining pipes with sealed connections or fastening components with uniform threads.

Advantages and Disadvantages of Pipe Threading Dies

Pipe threading dies provide precise threads for sealing applications in plumbing and gas lines, ensuring leak-proof connections with tapered threads that enhance joint integrity. They offer durability and compatibility with various pipe materials, enabling efficient onsite threading, but tend to be more specialized and expensive compared to bolt threading dies. However, pipe threading dies require careful alignment and skilled operation to prevent thread damage, limiting their use in general fastener applications unlike versatile bolt threading dies.

Advantages and Disadvantages of Bolt Threading Dies

Bolt threading dies offer precise thread cutting ideal for fasteners requiring strong, uniform threads, enhancing assembly strength and reliability. They provide versatility across various bolt sizes and materials but may wear faster on harder metals and require frequent recalibration to maintain accuracy. Unlike pipe threading dies, bolt threading dies typically produce finer threads suited for mechanical connections rather than sealing applications.

Choosing the Right Threading Die for Your Project

Selecting the appropriate threading die depends on the type of thread required; pipe threading dies create tapered threads for sealed pipe joints, whereas bolt threading dies produce straight threads for fasteners. Consider the material, thread size, and application--pipe threading dies suit plumbing and gas lines, while bolt threading dies are ideal for mechanical assemblies. Proper die selection ensures thread strength, fit, and durability, directly impacting project success and safety.

Pipe threading die vs bolt threading die Infographic

libmatt.com

libmatt.com