A sandblaster uses abrasive sand particles to remove tough rust, paint, or grime, making it ideal for heavy-duty cleaning and surface preparation. A bead blaster employs fine glass beads to gently polish or finish delicate surfaces without causing damage, offering precision control for restoring your items with a smooth finish.

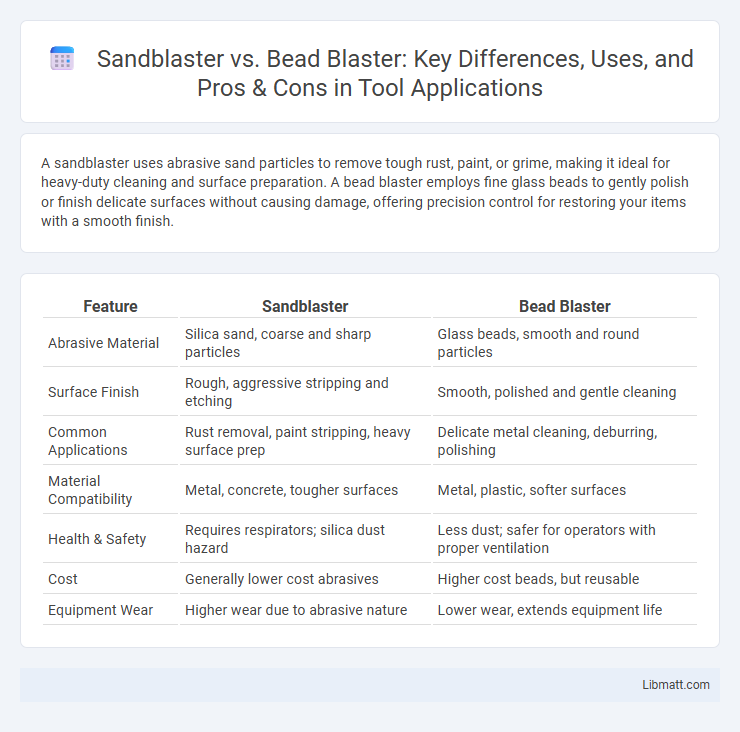

Table of Comparison

| Feature | Sandblaster | Bead Blaster |

|---|---|---|

| Abrasive Material | Silica sand, coarse and sharp particles | Glass beads, smooth and round particles |

| Surface Finish | Rough, aggressive stripping and etching | Smooth, polished and gentle cleaning |

| Common Applications | Rust removal, paint stripping, heavy surface prep | Delicate metal cleaning, deburring, polishing |

| Material Compatibility | Metal, concrete, tougher surfaces | Metal, plastic, softer surfaces |

| Health & Safety | Requires respirators; silica dust hazard | Less dust; safer for operators with proper ventilation |

| Cost | Generally lower cost abrasives | Higher cost beads, but reusable |

| Equipment Wear | Higher wear due to abrasive nature | Lower wear, extends equipment life |

Introduction to Sandblasting and Bead Blasting

Sandblasting propels abrasive materials like sand at high velocities to clean or etch surfaces, effectively removing rust, paint, and contaminants. Bead blasting uses fine glass or plastic beads to gently clean or polish delicate surfaces, providing a smooth finish without aggressive abrasion. Both methods are essential in surface preparation but differ in abrasiveness and application depending on the material and desired outcome.

How Sandblasters Work

Sandblasters operate by propelling abrasive particles, such as silica sand, at high velocity using compressed air to remove surface contaminants, rust, or paint on various materials. The abrasive media impacts the surface, effectively cleaning or etching it through mechanical abrasion without damaging the base material. This process creates a rough texture, enhancing adhesion for subsequent coatings or finishes.

How Bead Blasters Work

Bead blasters operate by propelling small, spherical abrasive beads at high velocity to clean or finish surfaces without causing significant damage. These glass or ceramic beads remove contaminants like rust, paint, and dirt through gentle abrasion, preserving the integrity of the underlying material. The controlled pressure and uniform shape of beads make bead blasting ideal for delicate surfaces, precision cleaning, and preparing metals for painting or coating.

Key Differences Between Sandblasting and Bead Blasting

Sandblasting uses abrasive materials like silica sand to remove surface coatings, rust, or paint, making it ideal for heavy-duty surface preparation. Bead blasting employs small glass beads, providing a gentler, non-destructive finish that enhances surface smoothness without significant material removal. Key differences include the type of abrasive used, surface impact, and suitability for different materials and applications, with sandblasting being more aggressive and bead blasting preferred for delicate or aesthetic surfaces.

Materials Used in Sandblasting vs. Bead Blasting

Sandblasting commonly employs abrasive materials such as silica sand, garnet, and aluminum oxide to remove rust, paint, or contaminants from surfaces. Bead blasting utilizes small, spherical media like glass beads, ceramic beads, or plastic beads, offering a gentler finish ideal for delicate surfaces. Your choice between sandblaster and bead blaster depends on the material compatibility and desired surface texture.

Surface Finish and Applications

Sandblasters deliver a rougher surface finish ideal for heavy-duty cleaning, rust removal, and stripping paint from metal or concrete surfaces. Bead blasters provide a smoother, more polished finish, making them suitable for delicate tasks like cleaning automotive parts or preparing surfaces for painting. Your choice depends on the desired surface texture and the material's sensitivity to abrasives.

Safety Considerations for Sandblasters and Bead Blasters

Sandblasters and bead blasters both require strict safety measures due to the high-velocity abrasive materials used, which can cause severe respiratory issues and skin injuries. Operators must wear personal protective equipment such as respirators, gloves, and full-body suits to prevent inhalation of silica dust or glass beads and avoid abrasive contact. Proper ventilation and containment systems are critical to minimize airborne particles and comply with occupational health and safety regulations.

Cost Comparison: Sandblaster vs Bead Blaster

Sandblasters typically have lower initial costs compared to bead blasters, but operational expenses can be higher due to abrasive media consumption and cleanup requirements. Bead blasters, while more expensive upfront, offer reusable media that reduces long-term costs and provides finer surface finishes, making them cost-effective for precision work. Evaluating Your project requirements and budget will help determine whether the sandblaster's affordability or the bead blaster's efficiency better suits Your needs.

Choosing the Right Blasting Method

Choosing the right blasting method depends on the surface material and desired finish, with sandblasters offering aggressive abrasion for tough surfaces, while bead blasters provide a gentler, more precise cleaning ideal for delicate items. Sandblasting equipment uses angular abrasive materials like silica sand for heavy-duty removal, whereas bead blasting relies on spherical glass beads to avoid surface damage. Understanding your project's requirements helps you select the optimal method to ensure effective cleaning or preparation without compromising the integrity of your material.

Frequently Asked Questions About Blasting Techniques

Sandblasting uses high-pressure air to propel abrasive materials like silica sand for surface cleaning and paint removal, whereas bead blasting employs fine glass beads to create a smoother, more polished finish ideal for delicate surfaces. Common questions often address the differences in media types, safety concerns related to silica dust exposure in sandblasting, and applications where bead blasting is preferred for non-destructive cleaning. Users also inquire about equipment costs, optimal pressure settings, and environmental considerations for each blasting technique.

Sandblaster vs bead blaster Infographic

libmatt.com

libmatt.com