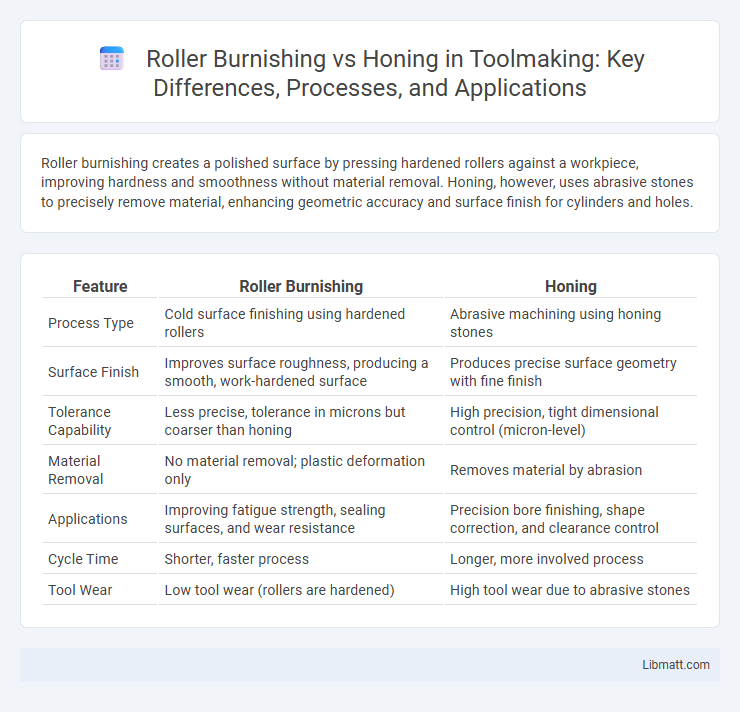

Roller burnishing creates a polished surface by pressing hardened rollers against a workpiece, improving hardness and smoothness without material removal. Honing, however, uses abrasive stones to precisely remove material, enhancing geometric accuracy and surface finish for cylinders and holes.

Table of Comparison

| Feature | Roller Burnishing | Honing |

|---|---|---|

| Process Type | Cold surface finishing using hardened rollers | Abrasive machining using honing stones |

| Surface Finish | Improves surface roughness, producing a smooth, work-hardened surface | Produces precise surface geometry with fine finish |

| Tolerance Capability | Less precise, tolerance in microns but coarser than honing | High precision, tight dimensional control (micron-level) |

| Material Removal | No material removal; plastic deformation only | Removes material by abrasion |

| Applications | Improving fatigue strength, sealing surfaces, and wear resistance | Precision bore finishing, shape correction, and clearance control |

| Cycle Time | Shorter, faster process | Longer, more involved process |

| Tool Wear | Low tool wear (rollers are hardened) | High tool wear due to abrasive stones |

Introduction to Surface Finishing Techniques

Roller burnishing and honing are advanced surface finishing techniques used to improve material properties such as surface roughness and hardness. Roller burnishing involves plastic deformation using hardened rollers, creating a smooth, work-hardened surface ideal for enhancing fatigue resistance. Honing uses abrasive stones to precisely control surface geometry and texture, making it suitable for applications requiring tight dimensional tolerances and fine finishes.

What is Roller Burnishing?

Roller burnishing is a cold-working surface finishing process that improves the surface texture and hardness of metal parts by pressing hardened rollers against the workpiece. This technique enhances dimensional accuracy and creates a smooth, reflective finish by deforming the peaks of rough surfaces without removing material. It is commonly used in applications requiring improved fatigue strength and wear resistance, such as automotive and aerospace components.

Understanding the Honing Process

The honing process refines the surface of a workpiece by using an abrasive stone to remove material and improve geometric accuracy and surface finish, creating precise bore diameters with enhanced cross-hatching for lubrication retention. In contrast, roller burnishing smooths and work-hardens the surface by plastically deforming it without material removal, improving surface hardness and fatigue resistance. Understanding honing enables your manufacturing process to achieve tight tolerances and optimal surface characteristics essential for high-performance components.

Key Differences Between Roller Burnishing and Honing

Roller burnishing utilizes hardened rollers to plastically deform and smooth the surface by cold working, resulting in enhanced surface finish and increased hardness without material removal, while honing employs abrasive stones to precisely remove material and correct dimensional errors for improved geometry and surface texture. Roller burnishing is ideal for cylindrical internal and external surfaces requiring high surface integrity and fatigue resistance, whereas honing is preferred for improving roundness, straightness, and size accuracy of bores. The critical difference lies in roller burnishing's ability to produce dense, compressive residual stresses, contrasting with honing's focus on abrasive shaping and fine surface refinement.

Surface Finish Quality Comparison

Roller burnishing produces a superior surface finish by plastic deformation that smooths peaks and fills valleys, often achieving roughness values as low as Ra 0.1 micrometers. Honing removes material to achieve precise geometric accuracy and a fine surface texture typically ranging from Ra 0.2 to 0.4 micrometers, with enhanced cross-hatch patterns for lubrication retention. Roller burnishing is preferred for applications requiring ultra-smooth finishes and fatigue resistance, while honing provides better control over bore geometry and is ideal for cylinder bores and hydraulic components.

Applications of Roller Burnishing vs Honing

Roller burnishing is ideal for improving surface finish and hardness in automotive components, aerospace parts, and hydraulic cylinders, providing enhanced fatigue resistance and dimensional accuracy. Honing is widely used for precision finishing of engine cylinder bores, hydraulic cylinders, and transmission parts to achieve tight tolerances and uniform crosshatch patterns crucial for lubrication retention. Your choice depends on whether surface hardening and improved wear resistance or precise geometric control and surface texture optimization are the primary application goals.

Material Suitability for Each Method

Roller burnishing is highly effective for ductile metals such as aluminum, copper, and low-carbon steel, providing a smooth surface finish and improved hardness by plastically deforming the material's surface. Honing is more suitable for harder materials like cast iron, high-carbon steel, and hardened alloys, where its abrasive stones remove material to achieve precise geometry and surface texture. Selecting the appropriate method depends on the material's hardness and desired surface characteristics, with roller burnishing ideal for softer metals and honing preferred for tougher, abrasive-resistant surfaces.

Productivity and Cost Efficiency

Roller burnishing enhances productivity by providing a faster surface finishing process with minimal material removal, reducing cycle times compared to honing. Cost efficiency is achieved through lower tool wear and maintenance expenses, as roller burnishing tools typically last longer than honing stones. Your manufacturing operation can benefit from reduced downtime and improved surface finish quality, contributing to overall lower production costs.

Maintenance and Tool Lifespan

Roller burnishing requires minimal maintenance due to its non-cutting process, which results in less tool wear and longer tool lifespan compared to honing; the hardened rollers maintain surface finish consistency over extended use. Honing tools, however, experience abrasive wear that necessitates frequent dressing and replacement, leading to higher maintenance costs and shorter operational life. Selecting roller burnishing as the surface finishing method enhances productivity by reducing downtime and tooling expenses associated with honing.

Choosing the Right Process for Your Needs

Roller burnishing and honing both enhance surface finish and dimensional accuracy but differ in application and results. Roller burnishing is ideal for hard, smooth surfaces, providing improved hardness and wear resistance, while honing excels at removing material for precise size control and surface texture. Consider your specific project requirements such as material hardness, desired tolerances, and surface finish to choose the right process for your needs.

Roller burnishing vs honing Infographic

libmatt.com

libmatt.com