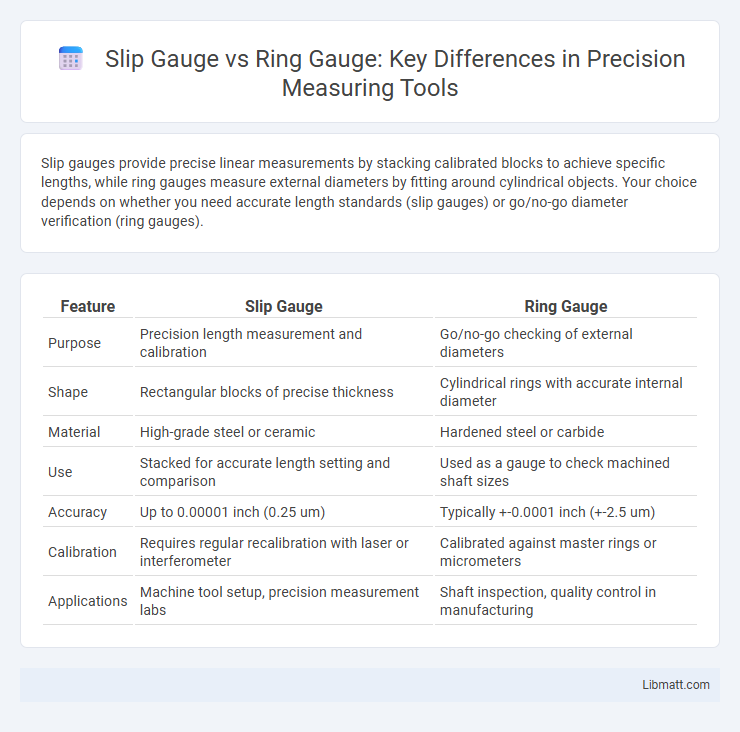

Slip gauges provide precise linear measurements by stacking calibrated blocks to achieve specific lengths, while ring gauges measure external diameters by fitting around cylindrical objects. Your choice depends on whether you need accurate length standards (slip gauges) or go/no-go diameter verification (ring gauges).

Table of Comparison

| Feature | Slip Gauge | Ring Gauge |

|---|---|---|

| Purpose | Precision length measurement and calibration | Go/no-go checking of external diameters |

| Shape | Rectangular blocks of precise thickness | Cylindrical rings with accurate internal diameter |

| Material | High-grade steel or ceramic | Hardened steel or carbide |

| Use | Stacked for accurate length setting and comparison | Used as a gauge to check machined shaft sizes |

| Accuracy | Up to 0.00001 inch (0.25 um) | Typically +-0.0001 inch (+-2.5 um) |

| Calibration | Requires regular recalibration with laser or interferometer | Calibrated against master rings or micrometers |

| Applications | Machine tool setup, precision measurement labs | Shaft inspection, quality control in manufacturing |

Introduction to Slip Gauge and Ring Gauge

Slip gauges are precision tools used for calibrating and measuring lengths with extremely high accuracy, often made from hardened steel or ceramic. Ring gauges are cylindrical measurement standards designed to check the external dimensions of parts, ensuring they meet specific tolerances. Your choice between slip gauge and ring gauge depends on whether you require precise length calibration or dimensional validation of cylindrical components.

Fundamental Differences Between Slip Gauge and Ring Gauge

Slip gauges are precision measurement tools used to calibrate and set lengths with extremely high accuracy, typically made from hardened steel or ceramic blocks. Ring gauges, on the other hand, serve as go/no-go gauges designed to check the external diameters of cylindrical parts for quality control. The fundamental difference lies in their application: slip gauges provide reference lengths for calibration, while ring gauges ensure dimensional conformity of manufactured components.

Construction and Material Composition

Slip gauges, constructed from high-grade steel or ceramic materials, feature precisely ground and carefully lapped surfaces to achieve exceptional flatness and dimensional accuracy. Ring gauges are typically crafted from hardened tool steel with a cylindrical shape, providing a durable and wear-resistant standard for measuring inside diameters. Both tools undergo heat treatment and surface finishing processes to maintain their dimensional stability and resistance to wear in precision measurement applications.

Principle of Operation

Slip gauges operate on the principle of gauge blocks wrung together to form precise lengths by molecular adhesion, allowing you to achieve highly accurate and stable reference measurements. Ring gauges function based on the fixed internal diameter of a hardened metal ring used to verify the external dimensions of cylindrical parts. Both tools provide traceable standards, but slip gauges offer adjustable lengths, while ring gauges ensure fixed-size verification.

Measurement Applications

Slip gauges provide highly precise length calibration for machine tools and inspection equipment, making them ideal for verifying linear dimensions. Ring gauges are primarily used for maintaining accuracy in cylindrical measurements such as diameters of shafts and holes. Your choice depends on whether you need to measure linear distances or verify internal/external circular dimensions.

Accuracy and Calibration Techniques

Slip gauges offer extremely high accuracy with tolerances often in the range of millionths of an inch, making them ideal for precision length measurements and calibration of other instruments. Ring gauges maintain tight dimensional tolerances through hardened steel construction, calibrated using optical comparators or coordinate measuring machines (CMMs) to ensure their dimensional integrity. Your choice between slip gauge and ring gauge should consider the required level of accuracy and the specific calibration standards employed.

Advantages of Slip Gauges

Slip gauges offer unparalleled precision in dimensional measurement, with accuracy levels reaching up to a few nanometers, making them essential for calibration standards in high-precision engineering. Their versatility allows stacking to create a wide range of lengths, providing a customizable and reliable reference that adapts to various measurement needs. Your quality control processes benefit significantly from slip gauges by ensuring consistent, repeatable measurements critical for maintaining manufacturing tolerances.

Advantages of Ring Gauges

Ring gauges provide quick and reliable Go/No-Go measurements, enhancing inspection efficiency in mass production. Their robust construction ensures long-term durability and dimensional stability, reducing calibration frequency and maintenance costs. The precise cylindrical shape of ring gauges allows for consistent measurement of external diameters with high accuracy, minimizing measurement errors.

Limitations and Challenges

Slip gauges face limitations in surface wear and accuracy degradation over time due to repeated handling and exposure to contaminants. Ring gauges encounter challenges related to thermal expansion affecting dimensional stability, which complicates precision measurements in varying temperature environments. Both tools require meticulous calibration and maintenance to ensure measurement reliability and mitigate errors.

Selecting the Right Gauge for Precision Measurement

Selecting the right gauge for precision measurement depends on the application's tolerance requirements and measurement type; slip gauges (gauge blocks) provide ultra-precise length standards with accuracy up to 0.00001 mm, ideal for calibration and high-precision machining. Ring gauges serve as go/no-go gauges primarily for verifying external diameters with fixed dimensions, offering quick, reliable inspection in manufacturing. Understanding the measurement context ensures optimal use of slip gauges for detailed calibration and ring gauges for pass/fail dimensional control.

Slip gauge vs ring gauge Infographic

libmatt.com

libmatt.com