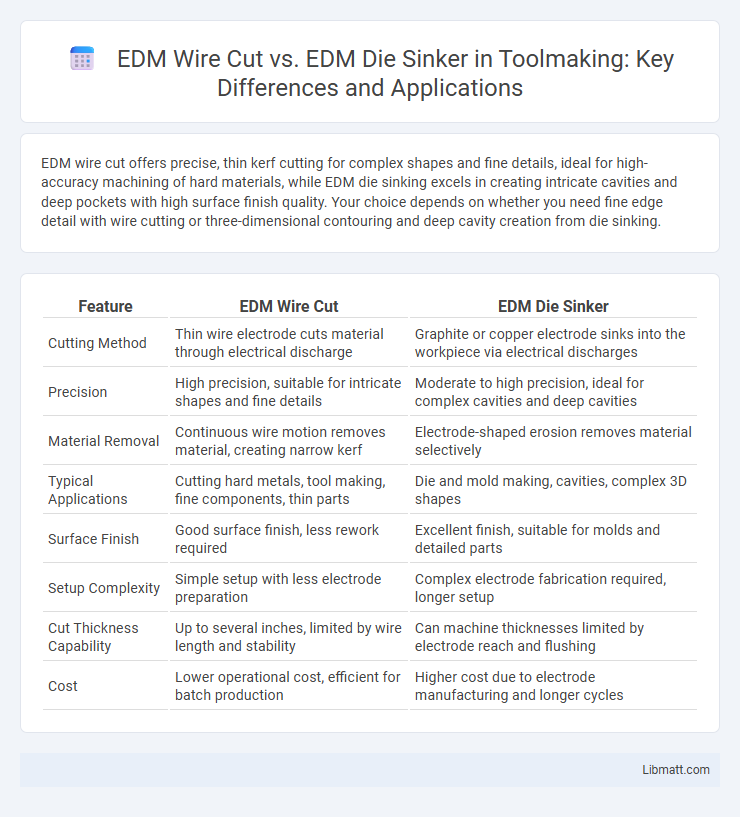

EDM wire cut offers precise, thin kerf cutting for complex shapes and fine details, ideal for high-accuracy machining of hard materials, while EDM die sinking excels in creating intricate cavities and deep pockets with high surface finish quality. Your choice depends on whether you need fine edge detail with wire cutting or three-dimensional contouring and deep cavity creation from die sinking.

Table of Comparison

| Feature | EDM Wire Cut | EDM Die Sinker |

|---|---|---|

| Cutting Method | Thin wire electrode cuts material through electrical discharge | Graphite or copper electrode sinks into the workpiece via electrical discharges |

| Precision | High precision, suitable for intricate shapes and fine details | Moderate to high precision, ideal for complex cavities and deep cavities |

| Material Removal | Continuous wire motion removes material, creating narrow kerf | Electrode-shaped erosion removes material selectively |

| Typical Applications | Cutting hard metals, tool making, fine components, thin parts | Die and mold making, cavities, complex 3D shapes |

| Surface Finish | Good surface finish, less rework required | Excellent finish, suitable for molds and detailed parts |

| Setup Complexity | Simple setup with less electrode preparation | Complex electrode fabrication required, longer setup |

| Cut Thickness Capability | Up to several inches, limited by wire length and stability | Can machine thicknesses limited by electrode reach and flushing |

| Cost | Lower operational cost, efficient for batch production | Higher cost due to electrode manufacturing and longer cycles |

Introduction to EDM Wire Cut and EDM Die Sinker

EDM Wire Cut uses a thin, continuously moving wire electrode to precisely cut complex shapes in hard metals, making it ideal for intricate and thin components. EDM Die Sinker employs a shaped electrode to erode material from a workpiece, best suited for creating cavities, molds, and dies with detailed features. Your choice between these methods depends on whether fine contour cutting or deep cavity shaping is required for your application.

Basic Principles of EDM Wire Cut

EDM Wire Cut uses a thin, electrically charged wire to precisely slice through metal by creating controlled sparks that erode material along a defined path. The process is highly accurate, enabling the production of complex shapes with minimal material distortion, particularly suited for cutting intricate outlines and fine contours. Your choice of EDM Wire Cut ensures efficient machining of hard metals where traditional cutting methods fall short.

Fundamental Process of EDM Die Sinker

EDM die sinker operates by using a specially shaped electrode submerged in dielectric fluid to erode material from the workpiece through controlled electrical discharges, enabling intricate 3D cavity formations. This process is ideal for creating complex molds, dies, and precision parts where detail and surface finish are critical. Your production benefits from the ability to achieve high accuracy and fine surface textures that wire cut EDM cannot replicate.

Key Differences Between Wire Cut and Die Sinker EDM

Wire cut EDM uses a thin, continuously moving wire as an electrode to precisely cut complex shapes in conductive materials, making it ideal for intricate outlines and tight tolerances. EDM die sinker employs a shaped electrode that is pressed into the workpiece to create cavities or deep cavities, excelling in 3D contouring and creating molds or dies. Your choice depends on the required geometry complexity, material thickness, and surface finish precision.

Material Compatibility of Wire Cut vs Die Sinker

EDM wire cut excels at machining hard and conductive materials like hardened steel, titanium, and exotic alloys with high precision and minimal thermal distortion. EDM die sinker is better suited for intricate cavity shaping in materials including hardened tool steels, carbides, and non-conductive materials when combined with powder-mixed die sinking. Your choice depends on material hardness, conductivity, and the complexity of the part geometry you need to achieve.

Precision and Surface Finish Comparison

EDM wire cut offers superior precision with tight tolerances around +-0.002 mm, ideal for intricate and detailed cuts, while EDM die sinker provides excellent precision but typically within +-0.005 mm. Surface finish from wire cut EDM usually achieves Ra values as low as 0.2 um, making it perfect for fine, smooth edges, whereas die sinker EDM attains finishes around 0.8 um, suitable for deeper cavities and complex geometries. Understanding these differences helps optimize Your manufacturing process based on precision requirements and desired surface quality.

Typical Applications for Each EDM Method

EDM wire cut excels in producing intricate shapes and fine details in materials like aerospace components, medical devices, and mold making, where precision and speed are critical. EDM die sinker is preferred for complex cavity machining, deep pockets, and three-dimensional molds commonly used in automotive dies, injection molding, and tool-and-die industries. Your choice between wire cut and die sinker EDM depends on the specific geometry and application requirements of your project.

Advantages and Limitations of Wire Cut EDM

Wire Cut EDM offers precise machining of complex shapes with minimal material distortion, making it ideal for hard metals and intricate parts. It allows for high accuracy and smooth surface finishes but is limited by slower cutting speeds compared to conventional machining and is less effective on very thick materials. The process also requires a continuous electrical conductivity in the workpiece, restricting its use on non-conductive materials.

Pros and Cons of Die Sinker EDM

EDM die sinker excels in creating complex, intricate shapes with high precision, especially in hard metals and deep cavities. Your projects benefit from its ability to machine detailed features without mechanical stress, but it often involves slower material removal rates and higher electrode costs compared to EDM wire cut. The main drawbacks include electrode wear and the need for frequent maintenance, requiring careful consideration of application requirements to determine suitability.

Choosing the Right EDM Method for Your Project

EDM wire cut offers precise, intricate cuts ideal for creating complex shapes with fine details, making it suitable for thin materials and high-volume production runs. EDM die sinker excels at producing deep cavities and intricate mold components with high accuracy, especially in hard materials requiring detailed contours. Understanding your project's material, complexity, and volume needs helps you select the best EDM method to optimize efficiency and quality.

EDM wire cut vs EDM die sinker Infographic

libmatt.com

libmatt.com