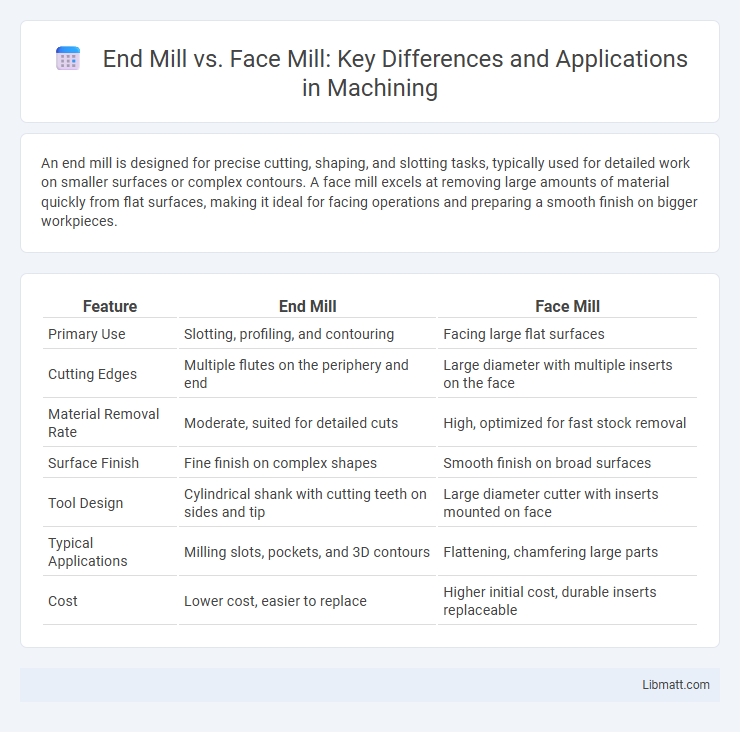

An end mill is designed for precise cutting, shaping, and slotting tasks, typically used for detailed work on smaller surfaces or complex contours. A face mill excels at removing large amounts of material quickly from flat surfaces, making it ideal for facing operations and preparing a smooth finish on bigger workpieces.

Table of Comparison

| Feature | End Mill | Face Mill |

|---|---|---|

| Primary Use | Slotting, profiling, and contouring | Facing large flat surfaces |

| Cutting Edges | Multiple flutes on the periphery and end | Large diameter with multiple inserts on the face |

| Material Removal Rate | Moderate, suited for detailed cuts | High, optimized for fast stock removal |

| Surface Finish | Fine finish on complex shapes | Smooth finish on broad surfaces |

| Tool Design | Cylindrical shank with cutting teeth on sides and tip | Large diameter cutter with inserts mounted on face |

| Typical Applications | Milling slots, pockets, and 3D contours | Flattening, chamfering large parts |

| Cost | Lower cost, easier to replace | Higher initial cost, durable inserts replaceable |

Introduction to End Mills and Face Mills

End mills are cutting tools used primarily for milling applications that involve side cutting and slotting, featuring multiple cutting edges on the periphery and tip. Face mills are designed for high-efficiency material removal on large, flat surfaces, utilizing multiple inserts mounted on a rotating cutter body. The choice between end mills and face mills depends on the specific machining requirements, such as the need for precision detailing or high-volume flat surface removal.

Key Differences Between End Mills and Face Mills

End mills feature a cylindrical cutting shape with flutes on the sides and tip, designed primarily for precision tasks like slotting, profiling, and plunging in milling operations. Face mills have a larger diameter with multiple cutting inserts on the face, optimized for removing large amounts of material quickly and producing smooth, flat surface finishes. End mills excel in detailed and intricate cutting, while face mills are preferred for high-efficiency surface machining on metals such as steel and aluminum.

Design and Construction of End Mills

End mills feature a cylindrical shape with cutting edges on the periphery and tip, designed for precision milling tasks such as slotting, profiling, and contouring. Their construction includes helical flutes that enhance chip removal and cutting efficiency, made from high-speed steel (HSS), carbide, or cobalt for durability. These tools vary in flute count and helix angle to optimize performance for specific materials and milling operations, distinguishing them from face mills that have larger diameter cutters primarily for surface finishing.

Structure and Features of Face Mills

Face mills feature a large, round cutter body equipped with multiple indexable carbide inserts arranged along the periphery, enabling efficient material removal on large surface areas. The insert geometry and robust construction allow face mills to achieve high feed rates and smooth finishes on flat surfaces, especially in steel and cast iron machining. Their design promotes heat dissipation and chip evacuation, contributing to extended tool life and enhanced milling performance in heavy-duty operations.

Applications: When to Use End Mills vs Face Mills

End mills excel in precision machining, ideal for detailed contouring, slotting, and profiling tasks on various materials, especially when working on intricate parts or tight spaces. Face mills are best suited for rapidly removing large amounts of material from flat surfaces, providing high efficiency in face milling, planing, and surface finishing operations on metal workpieces. Your choice between end mill vs face mill depends on the required surface finish, material removal rate, and the complexity of the machining task.

Cutting Techniques and Surface Finish Comparison

End mills excel in precision cutting, enabling intricate profiles and tight tolerances through multi-axis movements, while face mills prioritize rapid material removal with large-diameter cutters optimized for flat surfaces. Surface finish from end mills tends to be finer due to controlled chip load and gradual cutting depth, whereas face mills produce smoother finishes on broad surfaces by distributing cutting forces across multiple inserts. Your choice between end mill and face mill directly impacts machining efficiency and surface quality based on the specific cutting technique and desired finish.

Material Compatibility for End Mills and Face Mills

End mills excel in machining hard materials such as stainless steel, titanium, and hardened alloys due to their precise cutting edges and ability to perform complex profiles. Face mills are optimized for softer materials like aluminum and cast iron, delivering high material removal rates and smooth surface finishes on large flat surfaces. Material compatibility influences tool selection, with end mills preferred for detailed work and face mills for efficient bulk material removal in manufacturing processes.

Cost Considerations and Tooling Efficiency

End mills generally have a lower upfront cost compared to face mills, making them more budget-friendly for small-scale or precision machining tasks. Face mills provide greater tooling efficiency through faster material removal rates and longer tool life when machining large, flat surfaces, justifying their higher price in industrial applications. Choosing between them depends on balancing initial investment with operational productivity and wear resistance for specific machining needs.

Maintenance and Tool Lifespan

End mills require frequent inspection for wear and proper recalibration to maintain cutting precision, while face mills benefit from regular replacement of individual inserts to extend tool lifespan. Proper maintenance of End mill flutes ensures sharp cutting edges and reduced heat buildup, which directly impacts tool longevity. You can maximize the lifespan of both tools by implementing routine cleaning, lubrication, and timely replacement of worn components to prevent premature failure.

Choosing the Right Milling Tool for Your Needs

Selecting the right milling tool involves understanding the primary functions of end mills and face mills. End mills are versatile for detailed cutting, slotting, and profiling, while face mills excel in removing large surface areas quickly for flat finishes. Evaluating your project's material type, desired surface finish, and cutting depth helps determine whether an end mill or face mill best fits your machining requirements.

End mill vs face mill Infographic

libmatt.com

libmatt.com