An impact driver delivers high torque with rotational impacts, making it ideal for driving large screws and bolts quickly, while a drill driver offers versatile drilling and screwdriver functions with adjustable speed and torque settings. Choosing the right tool depends on Your project's needs; use an impact driver for heavy-duty fastening and a drill driver for precision tasks and versatile drilling.

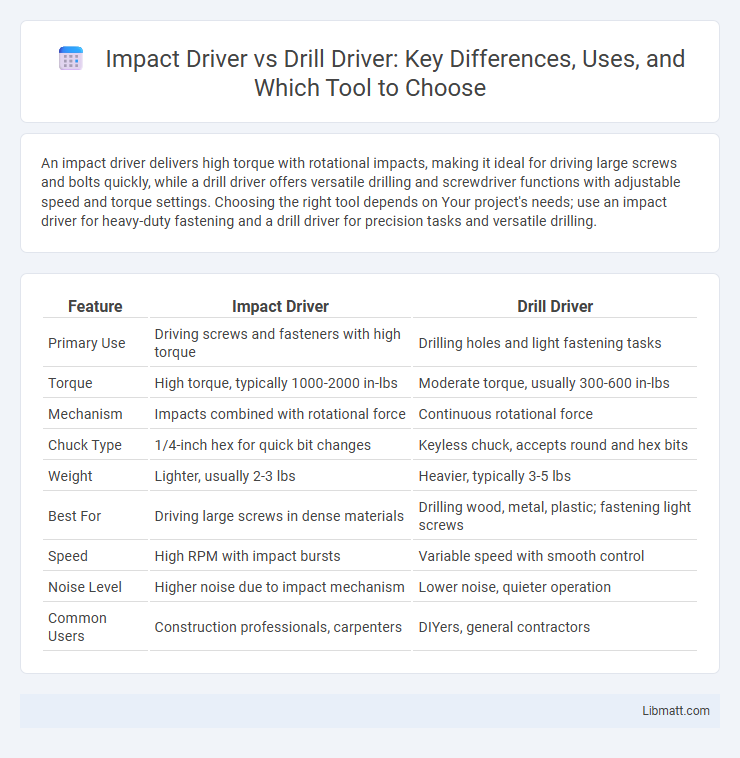

Table of Comparison

| Feature | Impact Driver | Drill Driver |

|---|---|---|

| Primary Use | Driving screws and fasteners with high torque | Drilling holes and light fastening tasks |

| Torque | High torque, typically 1000-2000 in-lbs | Moderate torque, usually 300-600 in-lbs |

| Mechanism | Impacts combined with rotational force | Continuous rotational force |

| Chuck Type | 1/4-inch hex for quick bit changes | Keyless chuck, accepts round and hex bits |

| Weight | Lighter, usually 2-3 lbs | Heavier, typically 3-5 lbs |

| Best For | Driving large screws in dense materials | Drilling wood, metal, plastic; fastening light screws |

| Speed | High RPM with impact bursts | Variable speed with smooth control |

| Noise Level | Higher noise due to impact mechanism | Lower noise, quieter operation |

| Common Users | Construction professionals, carpenters | DIYers, general contractors |

Introduction: Impact Driver vs Drill Driver

Impact drivers deliver high torque through concussive blows, making them ideal for driving long screws and bolts into tough materials, while drill drivers provide versatile drilling and driving capabilities suitable for a wide range of DIY and professional tasks. Your choice depends on the type of projects you tackle; impact drivers excel in tasks requiring power and precision with fasteners, whereas drill drivers offer better control for drilling holes and light screwdriving. Both tools often complement each other in a comprehensive toolkit to enhance efficiency and versatility.

Understanding Impact Drivers

Impact drivers deliver high torque through rapid rotational bursts, making them ideal for driving long screws and bolts into tough materials without stripping the fastener. Unlike drill drivers, which use a continuous rotational force for drilling holes and light fastening tasks, impact drivers combine rotational force with concussive blows to increase efficiency and reduce user fatigue. Your choice depends on whether your project requires aggressive fastening power or versatile drilling capabilities.

Understanding Drill Drivers

Drill drivers combine rotary drilling and driving functions, making them versatile tools for various home improvement projects. Featuring adjustable torque settings and variable speeds, these tools allow you to drill into wood, metal, and plastic while also driving screws with precision. Understanding drill drivers helps you select the right tool for tasks requiring controlled power and accuracy, especially when working on delicate materials.

Key Differences Between Impact Drivers and Drill Drivers

Impact drivers deliver high torque through rapid rotational impacts, making them ideal for driving long screws and heavy-duty fasteners, while drill drivers provide steady rotational force suitable for drilling holes and light fastening. Impact drivers typically use hex collets for quick bit changes, contrasting with drill drivers' three-jaw chucks that accommodate various bit sizes. The motor design of impact drivers reduces cam-out and enhances fastening efficiency, whereas drill drivers offer versatile speed and torque control for precise drilling tasks.

Power and Torque Comparison

Impact drivers deliver higher torque, typically ranging from 1,500 to 2,000 inch-pounds, making them ideal for heavy-duty fastening tasks. Drill drivers usually provide lower torque, around 400 to 700 inch-pounds, suitable for drilling holes and light fastening. The impact driver's hammering action generates bursts of high torque that outperform drill drivers in driving screws and bolts into tough materials.

Suitable Applications for Each Tool

Impact drivers excel in driving long screws and fasteners into dense materials like hardwood and metal, making them ideal for heavy-duty construction and automotive work. Drill drivers are better suited for precise drilling and light fastening tasks on softer materials such as wood, plastic, and drywall. Choosing between the two depends on the specific application, with impact drivers offering high torque for tough jobs and drill drivers providing better control for versatile drilling and fastening.

Pros and Cons of Impact Drivers

Impact drivers excel in delivering high torque and rapid bursts of rotational force, making them ideal for driving long screws and bolts efficiently, especially in tough materials. They tend to be more compact and lighter than drill drivers but can cause more noise and vibration, which might affect user comfort during extended use. Your choice depends on whether you prioritize power and speed over smoother operation and versatility for drilling tasks.

Pros and Cons of Drill Drivers

Drill drivers offer versatility and precision, excelling in drilling holes and driving screws in various materials, making them ideal for general household and woodworking tasks. They provide adjustable speed and torque settings for better control but may struggle with high-torque applications like driving long screws into hard materials. While drill drivers are lightweight and easy to handle, their limited impact force can result in slower performance compared to impact drivers for heavy-duty fastening jobs.

Which Tool Should You Choose?

Choosing between an impact driver and a drill driver depends on your specific needs and the types of projects you tackle. An impact driver excels at driving screws and bolts with high torque, making it ideal for construction and heavy-duty fastening tasks, while a drill driver offers more versatility for drilling holes and light to medium driving jobs. Your best choice balances power, control, and intended use to ensure efficiency and precision in your work.

Conclusion: Making the Right Decision

Choosing between an impact driver and a drill driver depends on Your specific needs: impact drivers excel at driving long screws and handling tough materials with high torque, while drill drivers offer versatility for drilling holes and lighter fastening tasks. For heavy-duty construction or automotive work, an impact driver provides superior performance due to its rotational impact mechanism. If Your projects require both drilling and occasional screwing, investing in a drill driver with variable speed settings ensures balanced functionality and ease of use.

Impact driver vs drill driver Infographic

libmatt.com

libmatt.com