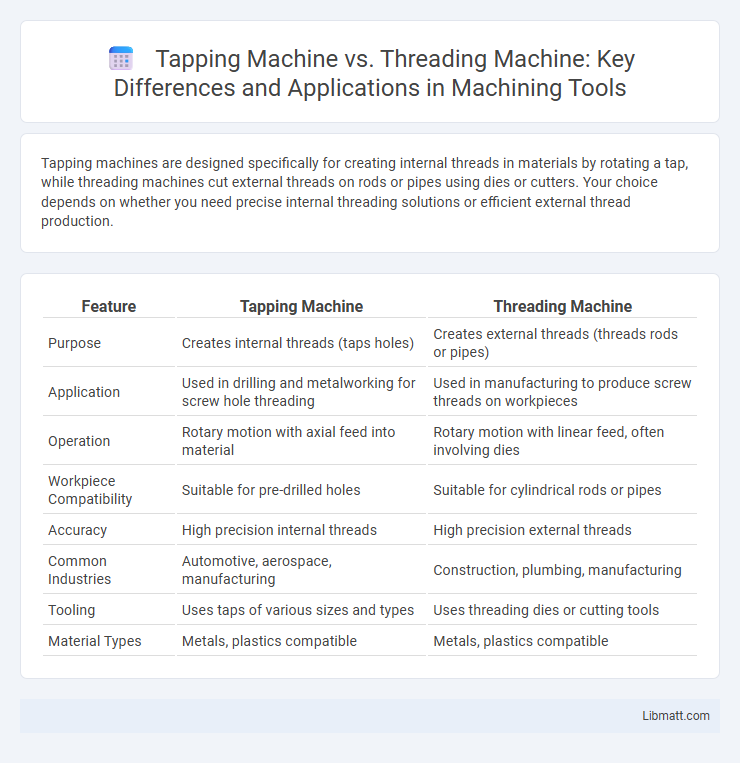

Tapping machines are designed specifically for creating internal threads in materials by rotating a tap, while threading machines cut external threads on rods or pipes using dies or cutters. Your choice depends on whether you need precise internal threading solutions or efficient external thread production.

Table of Comparison

| Feature | Tapping Machine | Threading Machine |

|---|---|---|

| Purpose | Creates internal threads (taps holes) | Creates external threads (threads rods or pipes) |

| Application | Used in drilling and metalworking for screw hole threading | Used in manufacturing to produce screw threads on workpieces |

| Operation | Rotary motion with axial feed into material | Rotary motion with linear feed, often involving dies |

| Workpiece Compatibility | Suitable for pre-drilled holes | Suitable for cylindrical rods or pipes |

| Accuracy | High precision internal threads | High precision external threads |

| Common Industries | Automotive, aerospace, manufacturing | Construction, plumbing, manufacturing |

| Tooling | Uses taps of various sizes and types | Uses threading dies or cutting tools |

| Material Types | Metals, plastics compatible | Metals, plastics compatible |

Introduction to Tapping and Threading Machines

Tapping machines are specialized tools designed for creating internal threads within pre-drilled holes by driving a tap into the material, enhancing precision and speed in metalworking. Threading machines focus on cutting external threads on rods or pipes, employing dies or thread-cutting tools to ensure accurate and consistent thread profiles. Both machines play essential roles in manufacturing processes by enabling efficient and reliable thread production for mechanical assemblies.

What is a Tapping Machine?

A tapping machine is a specialized tool designed to cut internal threads in materials such as metal, plastic, or wood, enabling screws or bolts to be securely inserted. It utilizes a rotating tap, synchronized to spin and move axially, ensuring precise and consistent thread creation in holes. Compared to threading machines that create external threads on rods or pipes, tapping machines focus exclusively on forming internal threads within pre-drilled holes.

What is a Threading Machine?

A threading machine is a specialized tool designed to cut precise threads on pipes or rods, ensuring accurate and consistent thread profiles for assembly or installation. It automates the threading process, increasing efficiency and reducing manual labor compared to traditional hand threading. Your choice between a tapping machine and a threading machine depends on whether you need to create internal threads (tapping) or external threads (threading).

Key Differences Between Tapping and Threading Machines

Tapping machines create internal threads by cutting into a pre-drilled hole, ideal for precise, consistent thread depths in metalworking or manufacturing. Threading machines form external threads on rods or bolts by rolling or cutting, suitable for creating durable fasteners with accurate pitch and diameter. Understanding these key differences helps you select the right machine for tasks requiring either internal or external threading processes.

Applications of Tapping Machines

Tapping machines are essential in manufacturing for creating precise internal threads in metal, plastic, and other materials, widely used in automotive, aerospace, and machinery industries. These machines enhance production efficiency by automating the tapping process, ensuring consistent thread quality and reducing manual labor. Your choice of tapping machine depends on factors like material type, hole size, and production volume for optimal application performance.

Applications of Threading Machines

Threading machines are primarily used in manufacturing and repair industries to create precise internal and external threads on pipes, rods, and fasteners, enabling secure mechanical joining. These machines are essential in plumbing, automotive, and construction applications where accurate and durable thread patterns ensure tight fittings and prevent leaks. Their capability to handle various thread sizes and materials makes them indispensable for both mass production and specialized threading tasks.

Advantages of Tapping Machines

Tapping machines offer precise and consistent threading, significantly improving production efficiency in metalworking industries. These machines reduce operator fatigue by automating the tapping process, ensuring uniform thread quality and minimizing the risk of tool breakage. Your manufacturing operation benefits from faster cycle times and lower maintenance costs compared to manual or threading machines.

Advantages of Threading Machines

Threading machines offer precise and consistent thread cutting, ensuring high-quality results for your manufacturing and repair needs. They reduce manual effort and increase production speed compared to tapping machines by automating the threading process. This efficiency makes threading machines ideal for industrial applications requiring durability and accuracy in threaded components.

Choosing the Right Machine for Your Needs

Selecting the right machine hinges on the specific application: tapping machines excel in creating internal threads efficiently for metalworking and fabrication, while threading machines are designed to cut precise external threads on pipes and rods. Consider factors such as material type, thread size, production volume, and portability requirements to optimize workflow and ensure high-quality results. Investing in a machine that aligns with your operational demands enhances productivity and reduces material waste.

Conclusion: Tapping vs Threading Machine

Tapping machines excel in creating internal threads by cutting precise holes for screws, while threading machines specialize in forming external threads on rods or pipes. Your choice depends on whether you need internal threading or external threading for manufacturing or repair tasks. Understanding these key differences ensures the correct machine enhances efficiency and thread quality in your projects.

Tapping machine vs threading machine Infographic

libmatt.com

libmatt.com