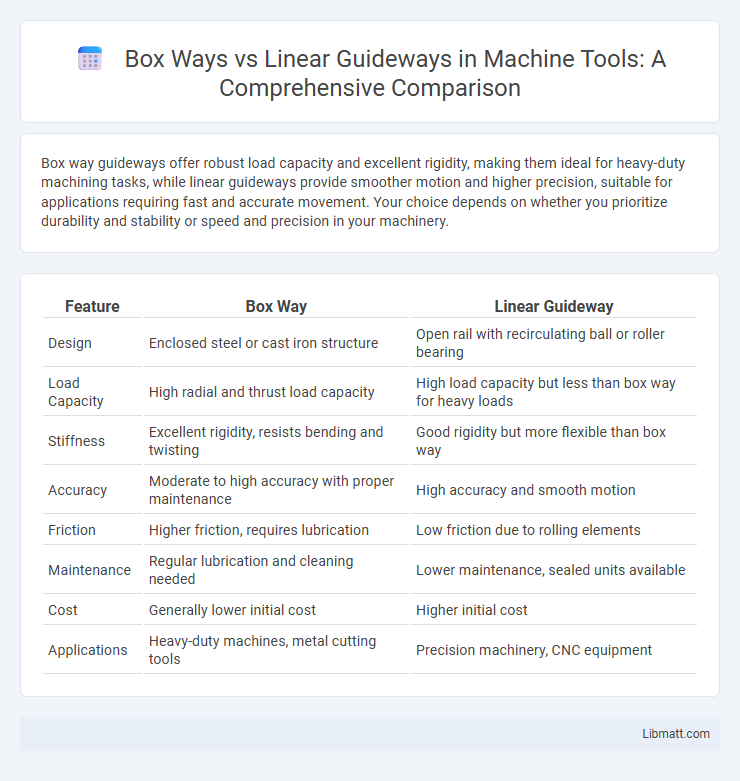

Box way guideways offer robust load capacity and excellent rigidity, making them ideal for heavy-duty machining tasks, while linear guideways provide smoother motion and higher precision, suitable for applications requiring fast and accurate movement. Your choice depends on whether you prioritize durability and stability or speed and precision in your machinery.

Table of Comparison

| Feature | Box Way | Linear Guideway |

|---|---|---|

| Design | Enclosed steel or cast iron structure | Open rail with recirculating ball or roller bearing |

| Load Capacity | High radial and thrust load capacity | High load capacity but less than box way for heavy loads |

| Stiffness | Excellent rigidity, resists bending and twisting | Good rigidity but more flexible than box way |

| Accuracy | Moderate to high accuracy with proper maintenance | High accuracy and smooth motion |

| Friction | Higher friction, requires lubrication | Low friction due to rolling elements |

| Maintenance | Regular lubrication and cleaning needed | Lower maintenance, sealed units available |

| Cost | Generally lower initial cost | Higher initial cost |

| Applications | Heavy-duty machines, metal cutting tools | Precision machinery, CNC equipment |

Introduction to Box Way and Linear Guideway

Box way guideways provide robust load capacity and superior rigidity, making them ideal for heavy-duty machining applications. Linear guideways offer high precision and smooth motion with minimal friction, suitable for high-speed and accurate positioning tasks. Your choice depends on balancing the requirements for durability versus precision in your machinery design.

Definition and Basic Structure

A box way guideway features a rectangular or square cross-section with enclosed sliding surfaces, providing high rigidity and load capacity suitable for heavy machining tasks. Linear guideways consist of a rail and a bearing block with rolling elements, designed for smooth and precise linear motion with lower friction. Understanding the basic structure helps you choose the appropriate guideway by balancing rigidity, accuracy, and application requirements.

Functionality and Working Principles

Box way guideways offer robust load-bearing capacity and high rigidity by enclosing the sliding element within a box-shaped structure, ensuring stable movement and vibration dampening in heavy-duty applications. Linear guideways utilize rolling elements such as balls or rollers between the rail and carriage, providing smooth, precise motion with reduced friction ideal for high-speed, high-precision tasks. The functional difference lies in the box way's sliding friction mechanism for sturdiness versus the linear guideway's rolling contact for accuracy and speed.

Performance in Precision and Accuracy

Box way guideways offer superior rigidity and load capacity, resulting in enhanced precision and minimal deflection under heavy loads, making them ideal for high-accuracy machining tasks. Linear guideways provide smoother motion and lower friction, contributing to consistent accuracy in fast, lightweight applications but may experience slight deflection under heavy cutting forces. The choice between box way and linear guideway systems directly impacts machine tool performance, with box ways excelling in precision stability and linear guideways favoring dynamic accuracy and speed.

Load Capacity and Rigidity Comparison

Box way systems offer superior load capacity and rigidity compared to linear guideways due to their enclosed design, which provides greater surface contact and distributes forces more evenly. The robust construction of box ways significantly reduces deflection under heavy loads, making them ideal for high-precision machining and heavy-duty applications. In contrast, linear guideways, while providing smoother motion and higher speed capabilities, typically exhibit lower rigidity and reduced load capacity, limiting their use in situations demanding extreme structural stiffness.

Speed and Acceleration Capabilities

Box way guideways provide higher rigidity and load capacity, enabling them to handle heavier loads at moderate speeds with smooth acceleration. Linear guideways excel in achieving faster speeds and rapid acceleration due to their lower friction and precise rolling elements, ideal for high-speed applications. Your choice depends on whether your priority is handling heavy loads with stable movement or maximizing speed and acceleration in precision tasks.

Maintenance and Durability Considerations

Box ways offer superior durability with their robust design, providing excellent resistance to heavy loads and shock, which reduces the frequency of maintenance in demanding industrial environments. Linear guideways require more frequent lubrication and cleaning to maintain precision and prevent wear, especially in dust-prone settings, which can increase maintenance efforts. Your choice between these systems should consider the operational environment and maintenance capacity to ensure long-term reliability.

Suitability for Different Machining Applications

Box way guideways provide superior rigidity and load capacity, making them ideal for heavy-duty machining tasks such as milling and boring, where high precision under substantial cutting forces is essential. Linear guideways offer smoother motion and higher-speed capabilities, making them suitable for applications like CNC machining and laser cutting that require rapid, precise movements with minimal friction. Your choice depends on the specific demands of the machining process, balancing load capacity against speed and accuracy requirements.

Cost and Investment Analysis

Box way guideways generally require a higher initial investment due to their robust design and superior load-carrying capacity, making them suitable for heavy-duty applications. Linear guideways tend to be more cost-effective upfront, offering easier installation and reduced maintenance expenses, which can lower your total cost of ownership in precision machining. Evaluating the balance between durability and upfront costs ensures your investment aligns with production demands and long-term operational efficiency.

Choosing the Right System for Your Needs

Box way guide systems offer superior rigidity and load capacity, making them ideal for heavy-duty applications requiring high precision and stability. Linear guideways provide smooth, low-friction motion with easier installation and maintenance, suitable for high-speed and light to medium load tasks. Assessing your machine's load requirements, speed, and precision needs helps determine the best guide system for your specific operational demands.

Box way vs linear guideway Infographic

libmatt.com

libmatt.com