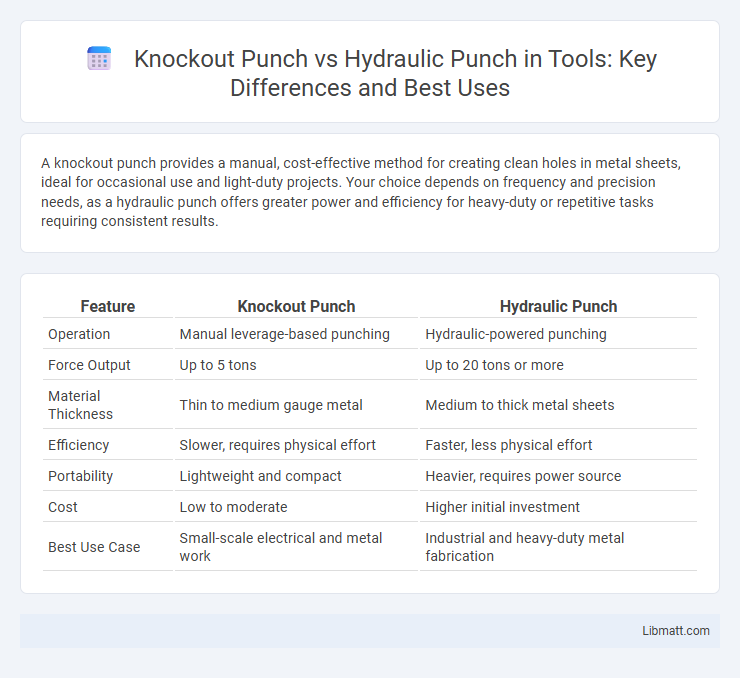

A knockout punch provides a manual, cost-effective method for creating clean holes in metal sheets, ideal for occasional use and light-duty projects. Your choice depends on frequency and precision needs, as a hydraulic punch offers greater power and efficiency for heavy-duty or repetitive tasks requiring consistent results.

Table of Comparison

| Feature | Knockout Punch | Hydraulic Punch |

|---|---|---|

| Operation | Manual leverage-based punching | Hydraulic-powered punching |

| Force Output | Up to 5 tons | Up to 20 tons or more |

| Material Thickness | Thin to medium gauge metal | Medium to thick metal sheets |

| Efficiency | Slower, requires physical effort | Faster, less physical effort |

| Portability | Lightweight and compact | Heavier, requires power source |

| Cost | Low to moderate | Higher initial investment |

| Best Use Case | Small-scale electrical and metal work | Industrial and heavy-duty metal fabrication |

Introduction to Knockout Punches and Hydraulic Punches

Knockout punches and hydraulic punches are essential tools for creating precise holes in metal sheets, with knockout punches relying on manual or electric force and hydraulic punches using fluid pressure for enhanced power and efficiency. Hydraulic punches deliver greater force with less physical effort, ideal for thicker or tougher materials, while knockout punches are typically more compact and portable for lighter tasks. Your choice depends on the required hole size, material thickness, and the level of power needed to achieve clean, accurate cuts.

How Knockout Punches Work

Knockout punches operate by using mechanical force generated through a manual or automatic driver to push a punch through sheet metal, creating precise holes without deforming the surrounding material. These tools consist of a punch and die set that align on either side of the metal, allowing clean cuts with minimal effort. Hydraulic punches, in contrast, use high-pressure hydraulic fluid to apply force, making them ideal for thicker or tougher materials but slower compared to knockout punches for lighter gauge metal.

Understanding Hydraulic Punches

Hydraulic punches provide precise, high-force punching capabilities, making them ideal for heavy-duty metal fabrication compared to manual knockout punches. With a hydraulic system that delivers consistent pressure, these punches reduce operator fatigue and improve efficiency in creating clean holes in thick materials. Their versatility and power make hydraulic punches essential for applications requiring accuracy and strength beyond the limits of traditional knockout punches.

Key Differences Between Knockout and Hydraulic Punches

Knockout punches use manual leverage to create clean holes in metal, offering portability and ease of use for lighter tasks, while hydraulic punches rely on fluid pressure to deliver high force for cutting thicker or tougher materials with greater precision. Hydraulic punches typically require less physical effort and produce smoother holes, making them ideal for professional or industrial applications where accuracy and efficiency are critical. Your choice between the two depends on the material thickness, required hole size, and frequency of use.

Material Compatibility and Application Scenarios

Knockout punches excel in punching through softer metals like aluminum, mild steel, and copper, making them ideal for electrical conduit work and thin sheet metals. Hydraulic punches handle thicker, harder materials such as stainless steel and heavy gauge steel, suitable for industrial fabrication and construction projects. Material compatibility determines the punch type choice, with knockout punches favored for light-duty tasks and hydraulic punches preferred for high-precision, heavy-duty applications.

Precision and Efficiency: Which Tool Performs Better?

Hydraulic punches deliver superior precision and efficiency compared to knockout punches due to their consistent hydraulic pressure, which ensures cleaner and more accurate hole cuts in metal sheets. Knockout punches rely on manual force, often resulting in variable precision and increased operator fatigue, reducing overall efficiency during repetitive tasks. Industrial applications requiring high accuracy and reduced cycle times typically favor hydraulic punches for optimal performance.

Safety Considerations for Each Punch Type

Knockout punches require manual force, increasing the risk of hand injuries and fatigue, so wearing protective gloves and ensuring proper grip is essential for Your safety. Hydraulic punches, powered by fluid pressure, significantly reduce physical effort and minimize strain, but demand regular maintenance checks to prevent leaks and ensure safe operation. Both punch types should be used with eye protection and within manufacturer-specified limits to avoid accidents during metal punching tasks.

Maintenance and Longevity Comparison

Knockout punches require minimal maintenance, primarily involving occasional lubrication and cleaning to prevent rust, which contributes to their long lifespan when used with proper care. Hydraulic punches demand more intensive upkeep, such as regular hydraulic fluid checks and seal replacements, but they offer superior durability under heavy-duty, continuous use. Your choice depends on the balance between low-maintenance needs and the hydraulic punch's potential for extended service life in demanding applications.

Cost Implications: Initial Investment and Operation

Knockout punches typically require a lower initial investment compared to hydraulic punches, making them more accessible for budget-conscious projects. Hydraulic punches, while more expensive upfront, offer greater efficiency and reduced manual effort, potentially lowering long-term operational costs. Your choice depends on balancing initial affordability with the value of faster, easier punching provided by hydraulic models.

Choosing the Right Punch for Your Project

Choosing the right punch for your project depends on the material thickness and precision required; knockout punches excel at creating clean holes in thinner metals, while hydraulic punches handle thicker, tougher materials with less manual effort. Your decision should consider the punch's tonnage capacity, ease of use, and the specific application, as hydraulic models provide consistent power and efficiency for repetitive tasks. Selecting the proper punch ensures optimal results, reduces tool wear, and improves overall workflow during metal fabrication.

Knockout punch vs hydraulic punch Infographic

libmatt.com

libmatt.com