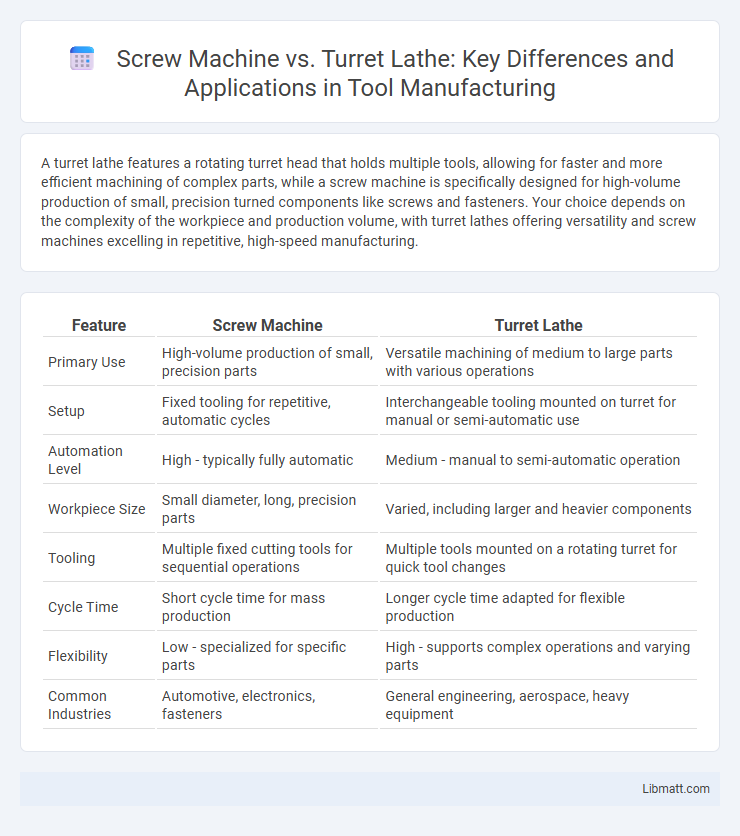

A turret lathe features a rotating turret head that holds multiple tools, allowing for faster and more efficient machining of complex parts, while a screw machine is specifically designed for high-volume production of small, precision turned components like screws and fasteners. Your choice depends on the complexity of the workpiece and production volume, with turret lathes offering versatility and screw machines excelling in repetitive, high-speed manufacturing.

Table of Comparison

| Feature | Screw Machine | Turret Lathe |

|---|---|---|

| Primary Use | High-volume production of small, precision parts | Versatile machining of medium to large parts with various operations |

| Setup | Fixed tooling for repetitive, automatic cycles | Interchangeable tooling mounted on turret for manual or semi-automatic use |

| Automation Level | High - typically fully automatic | Medium - manual to semi-automatic operation |

| Workpiece Size | Small diameter, long, precision parts | Varied, including larger and heavier components |

| Tooling | Multiple fixed cutting tools for sequential operations | Multiple tools mounted on a rotating turret for quick tool changes |

| Cycle Time | Short cycle time for mass production | Longer cycle time adapted for flexible production |

| Flexibility | Low - specialized for specific parts | High - supports complex operations and varying parts |

| Common Industries | Automotive, electronics, fasteners | General engineering, aerospace, heavy equipment |

Introduction to Screw Machines and Turret Lathes

Screw machines and turret lathes are specialized metalworking tools designed for high-volume production of precision turned components. Screw machines use cams or computer numerical control (CNC) to perform automated operations on small-diameter parts, ideal for producing screws, bolts, and fasteners efficiently. Turret lathes feature a rotating turret equipped with multiple cutting tools, enabling quick tool changes and versatile machining of various workpieces, which enhances your manufacturing productivity and precision.

Key Differences Between Screw Machines and Turret Lathes

Screw machines feature automatic bar-feeding capabilities designed for high-volume production of small, complex parts, while turret lathes offer manual or semi-automatic operation with a rotating turret holding multiple tools for varied machining tasks. The key differences lie in automation level, part size handling, and production speed, with screw machines excelling in rapid, repetitive manufacturing and turret lathes providing versatility for prototyping and larger components. Understanding these distinctions helps you select the right equipment based on your precision, volume, and flexibility requirements.

Construction and Design Features

Screw machines are typically constructed with a fixed headstock and a sliding headstock that moves along the bed, enabling automated, high-volume production of small to medium-sized parts with complex shapes. Turret lathes feature a rotating turret tool post allowing multiple cutting tools to be mounted and indexed sequentially, enhancing the machine's versatility for medium-duty jobs and varying production runs. Both machines incorporate rigid bed structures for stability, but screw machines emphasize automation for repetitive tasks, whereas turret lathes prioritize manual control and tooling flexibility.

Operational Principles of Screw Machines

Screw machines operate using automatic mechanisms to feed bar stock and perform multiple cutting operations like threading, drilling, and turning in a single cycle, optimizing precision in mass production. Turret lathes utilize a rotating turret to hold various cutting tools, enabling rapid tool changes for complex part machining but generally require manual or semi-automatic feeding. The operational principle of screw machines centers on continuous, automated stock feeding and synchronized tooling actions to achieve high-volume, consistent screw manufacturing.

How Turret Lathes Work

Turret lathes operate by holding multiple cutting tools on a turret, allowing rapid tool changes without stopping the machine, which significantly increases machining efficiency. The turret indexes to bring each tool into position for different cutting operations, enabling complex parts to be produced with minimal manual intervention. Your production process benefits from reduced cycle times and enhanced precision when using turret lathes compared to traditional screw machines.

Types of Materials Machined

Screw machines excel in machining small, high-volume parts from materials like aluminum, brass, steel, and stainless steel, making them ideal for precision components in industries such as automotive and electronics. Turret lathes handle a broader range of materials including tougher metals like cast iron, bronze, and titanium, suited for versatile machining needs requiring multiple operations on medium to large workpieces. Your choice depends on the material hardness and production volume, with screw machines favoring lighter alloys for speed and turret lathes accommodating heavier, more complex materials.

Production Speed and Efficiency Comparison

Screw machines offer high production speed ideal for small to medium-sized parts with repetitive threading tasks, maximizing efficiency through automated tool changes. Turret lathes excel in handling more complex, multi-operation parts by holding multiple tools simultaneously, reducing setup time and increasing workflow versatility. Your manufacturing process can benefit from selecting a screw machine for simpler, high-volume runs and a turret lathe when flexibility and varied operations are required.

Precision and Accuracy Analysis

Screw machines offer high precision and repeatability ideal for producing small, intricate parts with tight tolerances, thanks to their automated multi-spindle design. Turret lathes provide excellent accuracy for larger, complex workpieces by allowing quick tool changes and rigid workholding, which enhances dimensional control. Your choice depends on the part size and tolerance requirements, with screw machines excelling in mass production of precise components and turret lathes in versatile, accurate machining of varied parts.

Typical Applications in Manufacturing

Screw machines excel in producing high-volume, small to medium-sized precision parts such as screws, bolts, and fasteners, often used in automotive and electronics industries. Turret lathes are ideal for medium to large batch production, handling complex components requiring multiple operations like fittings and valves in aerospace and heavy machinery sectors. Choosing the right machine enhances your manufacturing efficiency by matching production needs with the machine's capabilities.

Choosing Between Screw Machine and Turret Lathe: Factors to Consider

Choosing between a screw machine and a turret lathe depends on production volume, precision requirements, and part complexity. Screw machines excel in high-volume, small-diameter, and thread-intensive components with rapid cycle times, while turret lathes provide versatility for larger, more complex parts with multiple machining operations. Key factors include tooling flexibility, setup time, and cost efficiency relative to the specific manufacturing application.

Screw machine vs turret lathe Infographic

libmatt.com

libmatt.com