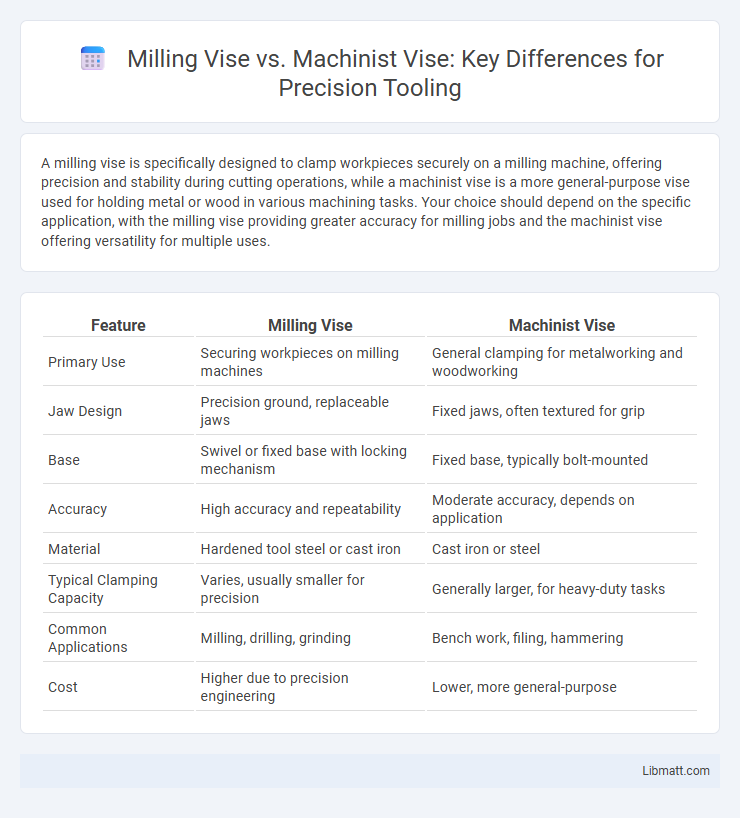

A milling vise is specifically designed to clamp workpieces securely on a milling machine, offering precision and stability during cutting operations, while a machinist vise is a more general-purpose vise used for holding metal or wood in various machining tasks. Your choice should depend on the specific application, with the milling vise providing greater accuracy for milling jobs and the machinist vise offering versatility for multiple uses.

Table of Comparison

| Feature | Milling Vise | Machinist Vise |

|---|---|---|

| Primary Use | Securing workpieces on milling machines | General clamping for metalworking and woodworking |

| Jaw Design | Precision ground, replaceable jaws | Fixed jaws, often textured for grip |

| Base | Swivel or fixed base with locking mechanism | Fixed base, typically bolt-mounted |

| Accuracy | High accuracy and repeatability | Moderate accuracy, depends on application |

| Material | Hardened tool steel or cast iron | Cast iron or steel |

| Typical Clamping Capacity | Varies, usually smaller for precision | Generally larger, for heavy-duty tasks |

| Common Applications | Milling, drilling, grinding | Bench work, filing, hammering |

| Cost | Higher due to precision engineering | Lower, more general-purpose |

Introduction to Milling Vise vs Machinist Vise

A milling vise is designed to secure workpieces firmly on milling machines, offering high precision and rigidity for complex machining tasks, while a machinist vise is more versatile, commonly used for general metalworking and holding objects during filing or sawing. Milling vises often have hardened steel jaws and precision-ground bases to minimize deflection, whereas machinist vises prioritize clamping strength and adjustability. Understanding the differences helps you choose the right tool for accuracy or versatility in your workshop.

Key Differences Between Milling and Machinist Vises

Milling vises are specifically engineered for securing workpieces during milling operations, featuring precision dovetail slides and swivel bases for angular adjustments. Machinist vises focus on holding materials firmly during general machining tasks, typically without the specialized adjustments found in milling vises. The key differences lie in milling vises' enhanced clamping stability and positioning accuracy, critical for precise cuts, compared to the robust but less adjustable design of machinist vises.

Design and Construction Comparison

Milling vises feature a robust, low-profile design with hardened steel jaws and a precision-ground base to ensure stable workpiece clamping during high-torque milling operations. Machinist vises typically have a heavier cast iron body with swivel bases and replaceable steel jaws, optimized for versatility in holding various metalworking components. The milling vise's compact, fixed design prioritizes alignment accuracy and rigidity, whereas the machinist vise emphasizes adaptability and broad functionality in general workshop tasks.

Clamping Force and Precision

A Milling vise provides higher clamping force essential for securing workpieces during heavy milling operations, ensuring minimal movement and maximum stability. In contrast, a machinist vise offers superior precision alignment and fine adjustment capabilities, making it ideal for delicate or detailed machining tasks. Your choice between the two should prioritize whether clamping strength or angular accuracy is more critical for your specific application.

Applications in Metalworking

Milling vises are specifically designed to securely hold metal workpieces during milling operations, providing precise clamping and minimal movement for accurate machining. Machinist vises offer versatility for general metalworking tasks such as filing, grinding, and assembly, but they lack the rigidity and flat mounting base necessary for milling machines. Your choice between these vises should align with the specific demands of precision milling versus broader metalworking applications.

Accuracy and Repeatability

Milling vises offer higher accuracy and repeatability compared to machinist vises due to their precision ground surfaces and robust clamping mechanisms, ensuring minimal workpiece movement during machining processes. Machinist vises typically provide solid holding power but may lack the fine adjustment features critical for achieving tight tolerances in milling operations. The enhanced rigidity and alignment features of milling vises result in superior precision, making them ideal for applications demanding consistent, repeatable positioning.

Ease of Use and Versatility

A milling vise offers precise adjustment with smooth jaw movement, making it easier for users to secure irregular workpieces during milling operations. Machinist vises provide robust clamping strength and versatility, suitable for various workshop tasks beyond milling, including filing and assembly. Your choice depends on balancing ease of use with the specific versatility required for different machining activities.

Durability and Maintenance

Milling vises typically feature hardened steel construction with precision-ground surfaces, offering exceptional durability for heavy-duty machining tasks and requiring minimal maintenance to retain their gripping accuracy. Machinist vises, while also robust, often utilize ductile iron or cast steel, making them durable but more prone to wear, necessitating regular cleaning and lubrication to prevent rust and ensure smooth operation. Choosing the right vise for your setup depends on balancing the need for long-lasting durability with the maintenance routine you can maintain.

Cost Considerations

Milling vises generally cost more than machinist vises due to their specialized clamping mechanisms designed for precision on milling machines. Machinist vises offer a more affordable option suitable for general workholding but may lack the rigidity and accuracy essential for milling operations. Evaluating the balance between upfront investment and required precision is critical when selecting between the two types of vises.

Choosing the Right Vise for Your Workshop

Choosing the right vise for your workshop depends on the specific tasks and precision required; milling vises offer superior clamping accuracy for milling machines, securing workpieces during intricate machining processes. Machinist vises provide versatile clamping for general metalworking and assembly, with adjustable jaws suitable for various shapes and materials. Prioritize a milling vise for high-precision operations and a machinist vise for flexible, multi-purpose use to optimize efficiency and accuracy in your projects.

Milling vise vs machinist vise Infographic

libmatt.com

libmatt.com