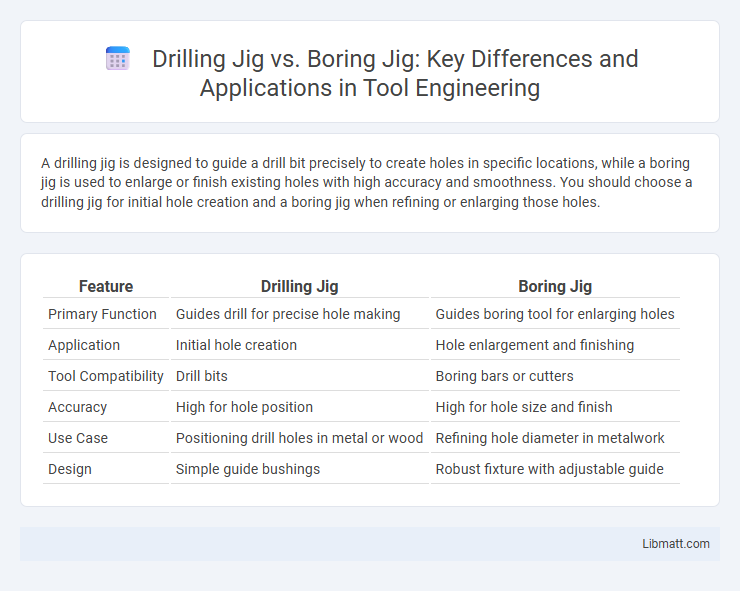

A drilling jig is designed to guide a drill bit precisely to create holes in specific locations, while a boring jig is used to enlarge or finish existing holes with high accuracy and smoothness. You should choose a drilling jig for initial hole creation and a boring jig when refining or enlarging those holes.

Table of Comparison

| Feature | Drilling Jig | Boring Jig |

|---|---|---|

| Primary Function | Guides drill for precise hole making | Guides boring tool for enlarging holes |

| Application | Initial hole creation | Hole enlargement and finishing |

| Tool Compatibility | Drill bits | Boring bars or cutters |

| Accuracy | High for hole position | High for hole size and finish |

| Use Case | Positioning drill holes in metal or wood | Refining hole diameter in metalwork |

| Design | Simple guide bushings | Robust fixture with adjustable guide |

Introduction to Drilling Jigs and Boring Jigs

Drilling jigs and boring jigs are precision tools designed to guide drills and boring tools accurately during manufacturing processes. Drilling jigs ensure proper alignment and positioning for hole creation, while boring jigs provide stability and control for enlarging existing holes with high precision. Understanding the specific purpose of these jigs can improve your machining accuracy and efficiency.

Key Differences Between Drilling Jigs and Boring Jigs

Drilling jigs guide twist drills for creating precise holes, typically used in fabricating components requiring exact hole placement and alignment. Boring jigs, on the other hand, hold boring tools to enlarge pre-drilled holes with higher accuracy and finish quality, often used in heavy machinery and engine parts. The primary difference lies in their function: drilling jigs assist in hole creation while boring jigs are designed for hole enlargement and refinement, impacting tool design, accuracy, and application scope.

Function and Purpose of Drilling Jigs

Drilling jigs are designed to guide drilling tools precisely, ensuring accurate hole placement and consistent depth during manufacturing processes. Unlike boring jigs, which are used to enlarge or finish holes with high precision, drilling jigs focus on proper alignment and stability for initial hole creation. Your production efficiency improves significantly when using drilling jigs, as they reduce errors and maintain uniformity across multiple parts.

Function and Purpose of Boring Jigs

Boring jigs are designed to guide boring tools for precision enlarging of existing holes, ensuring exact diameter and accurate alignment. Unlike drilling jigs that create holes, boring jigs focus on improving hole accuracy and surface finish. Your machining process benefits from boring jigs when precise hole tolerance and concentricity are critical.

Design Features of Drilling Jigs

Drilling jigs are designed with bushings to guide drill bits accurately and ensure precise hole placement, featuring clamping mechanisms to secure the workpiece and maintain repeatability. Their robust frame minimizes vibrations, enhancing drilling accuracy and tool longevity. Unlike boring jigs, drilling jigs prioritize easy setup and quick tool changes, optimizing efficiency for high-volume repetitive drilling tasks.

Design Features of Boring Jigs

Boring jigs feature a rigid frame with precisely positioned bushings to guide the boring tool for accurate hole enlargement or finishing. Their design incorporates adjustable components to accommodate varying hole sizes and ensure consistent alignment during machining. Unlike drilling jigs, boring jigs often include support mechanisms to minimize vibration and maintain high precision in the boring process.

Applications in Modern Manufacturing

Drilling jigs are extensively used in modern manufacturing for precise hole positioning in components such as engine blocks and aircraft parts, ensuring repeatability and reducing operator error. Boring jigs, on the other hand, are specialized for enlarging existing holes with extreme accuracy, commonly applied in heavy machinery and aerospace industries where tight tolerances are critical. Both jigs enhance productivity and maintain consistency in high-volume production processes by guiding tools to exact locations on workpieces.

Advantages and Limitations of Each Jig

Drilling jigs offer high precision and repeatability for creating holes, enhancing productivity in mass production but are limited to specific hole sizes and depths. Boring jigs provide superior accuracy for enlarging existing holes and can achieve tighter tolerances, though they require more setup time and are less efficient for high-volume runs. Choosing between drilling and boring jigs depends on the required hole finish, dimensional accuracy, and production volume.

Selection Criteria: When to Use Drilling vs. Boring Jigs

Drilling jigs are ideal for creating precise holes where the required diameter matches the drill bit exactly, making them suitable for simpler, high-volume production tasks. Boring jigs are preferred when hole accuracy and finish quality must be enhanced beyond drilling capabilities, especially for enlarging or finishing previously drilled holes. Your choice depends on whether the operation demands initial hole creation or precise hole enlargement and surface refinement.

Future Trends in Jig Technology

Future trends in jig technology emphasize automation and precision, with drilling jigs integrating advanced CNC controls and IoT sensors to enhance real-time monitoring and reduce human error. Boring jigs are evolving with adaptive tooling systems that adjust automatically to material variations, significantly improving accuracy and cycle times. The incorporation of AI-driven diagnostics and additive manufacturing techniques is poised to revolutionize jig customization and predictive maintenance across both drilling and boring applications.

Drilling jig vs boring jig Infographic

libmatt.com

libmatt.com