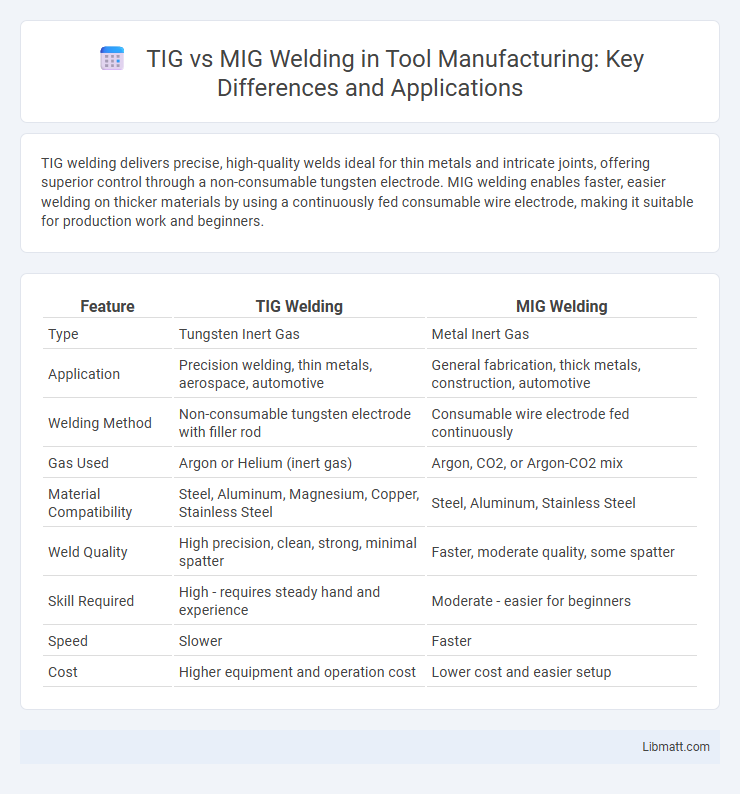

TIG welding delivers precise, high-quality welds ideal for thin metals and intricate joints, offering superior control through a non-consumable tungsten electrode. MIG welding enables faster, easier welding on thicker materials by using a continuously fed consumable wire electrode, making it suitable for production work and beginners.

Table of Comparison

| Feature | TIG Welding | MIG Welding |

|---|---|---|

| Type | Tungsten Inert Gas | Metal Inert Gas |

| Application | Precision welding, thin metals, aerospace, automotive | General fabrication, thick metals, construction, automotive |

| Welding Method | Non-consumable tungsten electrode with filler rod | Consumable wire electrode fed continuously |

| Gas Used | Argon or Helium (inert gas) | Argon, CO2, or Argon-CO2 mix |

| Material Compatibility | Steel, Aluminum, Magnesium, Copper, Stainless Steel | Steel, Aluminum, Stainless Steel |

| Weld Quality | High precision, clean, strong, minimal spatter | Faster, moderate quality, some spatter |

| Skill Required | High - requires steady hand and experience | Moderate - easier for beginners |

| Speed | Slower | Faster |

| Cost | Higher equipment and operation cost | Lower cost and easier setup |

Introduction to TIG and MIG Welding

TIG welding (Tungsten Inert Gas) uses a tungsten electrode to produce precise, high-quality welds ideal for thin metals and intricate projects, while MIG welding (Metal Inert Gas) employs a continuously fed wire electrode for faster, more efficient welding on thicker materials. Each method requires different equipment and techniques, with TIG offering greater control and MIG providing higher productivity for heavy-duty applications. Choosing between TIG and MIG welding depends on your project's material type, thickness, and desired weld quality.

Key Differences Between TIG and MIG Welding

TIG welding uses a non-consumable tungsten electrode and requires a separate filler material, providing precise control and cleaner welds ideal for thin metals and intricate work. MIG welding employs a consumable wire electrode fed continuously through the welding gun, enabling faster welds suited for thicker materials and production environments. TIG welding is preferred for high-quality, detailed applications, while MIG welding offers speed and ease for general fabrication and repair tasks.

Process Overview: How TIG Welding Works

Tungsten Inert Gas (TIG) welding uses a non-consumable tungsten electrode to produce the weld, while a separate filler rod is manually fed into the weld pool. An inert gas, typically argon or helium, shields the weld area to prevent oxidation and contamination. This process enables precise control over heat input and weld quality, making TIG ideal for thin materials and critical welds.

Process Overview: How MIG Welding Works

MIG welding, or Metal Inert Gas welding, uses a continuous solid wire electrode fed through a welding gun and into the weld pool, creating a strong bond between the base metals. The process relies on an inert gas shield, typically argon or a mix of argon and carbon dioxide, to protect the weld from atmospheric contamination. MIG welding is efficient for joining thin to medium-thickness metal components in automotive, construction, and manufacturing applications.

Suitability for Different Materials

TIG welding excels in precision and is ideal for thin materials such as stainless steel, aluminum, and non-ferrous metals, offering superior control and cleaner welds. MIG welding suits thicker materials like mild steel and is favored in automotive and construction industries due to its speed and ease of use. Material compatibility depends on factors including metal type, thickness, and required weld quality, making TIG preferable for delicate tasks and MIG for rapid production.

Welding Applications in Industry

TIG welding excels in industries requiring precision and clean welds, such as aerospace, automotive, and nuclear sectors, due to its ability to weld thin materials and produce high-quality joints. MIG welding is widely used in heavy-duty industrial applications like construction, shipbuilding, and manufacturing, offering faster welding speeds and ease of use on thicker metals. Both techniques serve critical roles, with TIG favored for detailed, high-strength welds and MIG preferred for high-volume production and structural work.

Equipment and Setup Requirements

TIG welding requires more precise equipment, including a constant current power supply, a tungsten electrode, and an inert gas like argon for shielding, making its setup more complex and suited for detailed work. MIG welding uses a wire feed system with a continuous electrode and typically requires a simpler setup with a shielding gas blend or flux-cored wire, allowing quicker preparation and easier handling for various thicknesses. Your choice between TIG and MIG welding equipment will depend on the level of control you need and the specific applications you aim to achieve.

Advantages of TIG Welding

TIG welding provides superior precision and control, making it ideal for intricate and thin metal work requiring high-quality, clean welds with minimal spatter. It offers excellent versatility by welding a wide range of metals, including stainless steel, aluminum, and copper alloys, resulting in strong, aesthetically pleasing joints. Your projects benefit from TIG's ability to produce durable welds with enhanced corrosion resistance and minimal post-weld cleanup.

Advantages of MIG Welding

MIG welding offers faster welding speeds and greater ease of use, making it ideal for beginners and production environments requiring high efficiency. This process produces cleaner welds with minimal splatter due to continuous wire feeding and shielding gas supply. MIG welding accommodates a wide range of metal thicknesses and types, enhancing versatility for automotive, construction, and fabrication industries.

Choosing the Right Welding Method for Your Project

TIG welding offers superior precision and control, making it ideal for projects requiring high-quality, clean welds on thin materials like stainless steel and aluminum. MIG welding provides faster welding speeds and ease of use, suitable for thicker materials and larger construction tasks where efficiency is prioritized. Evaluating factors such as metal type, thickness, desired weld appearance, and project complexity ensures the optimal welding method for achieving durable and reliable results.

TIG vs MIG welding Infographic

libmatt.com

libmatt.com