A jig bore excels in precision hole location and size control, making it ideal for complex workpieces requiring exact hole alignment, while a jig grinder specializes in finishing and enlarging holes or contours with high accuracy. Understanding the specific needs of your machining project helps determine whether a jig bore or jig grinder is more suitable for achieving optimal results.

Table of Comparison

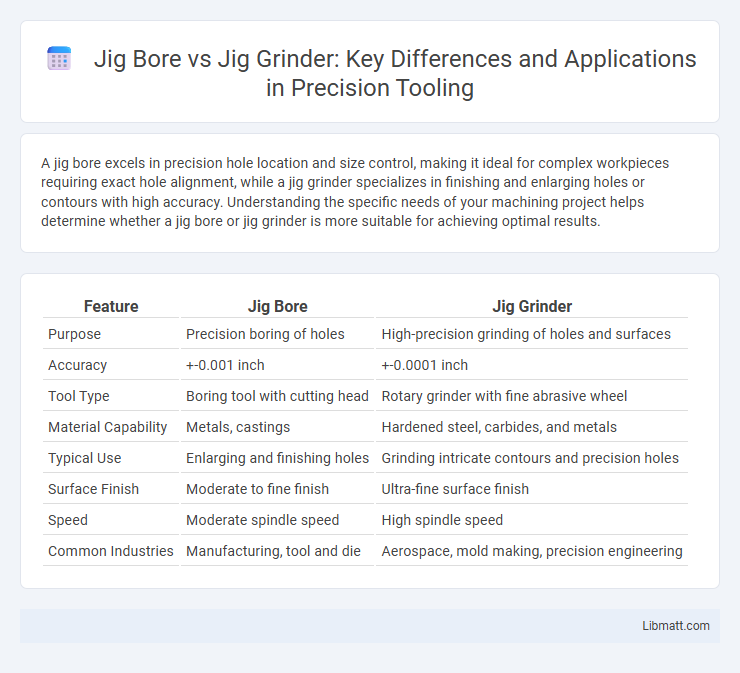

| Feature | Jig Bore | Jig Grinder |

|---|---|---|

| Purpose | Precision boring of holes | High-precision grinding of holes and surfaces |

| Accuracy | +-0.001 inch | +-0.0001 inch |

| Tool Type | Boring tool with cutting head | Rotary grinder with fine abrasive wheel |

| Material Capability | Metals, castings | Hardened steel, carbides, and metals |

| Typical Use | Enlarging and finishing holes | Grinding intricate contours and precision holes |

| Surface Finish | Moderate to fine finish | Ultra-fine surface finish |

| Speed | Moderate spindle speed | High spindle speed |

| Common Industries | Manufacturing, tool and die | Aerospace, mold making, precision engineering |

Introduction to Jig Bore and Jig Grinder

A Jig bore is a precision machining tool designed for accurately enlarging and finishing holes with tight tolerances, commonly used in jig and fixture manufacturing. A Jig grinder is a specialized machine tool intended for grinding complex shapes and holes, offering high-speed spindle operation for fine surface finishes and precise dimension control. Both tools enhance machining accuracy but serve different purposes in achieving detailed workpiece geometries.

Key Differences Between Jig Bore and Jig Grinder

Jig bore machines excel in precision hole location and size, typically used for drilling and boring operations with tolerances within a few thousandths of an inch. Jig grinders specialize in finishing operations, achieving extremely tight tolerances and complex surface contours through high-speed spindle grinding. Your choice depends on whether you prioritize accurate hole placement with moderate tolerance (jig bore) or ultra-fine surface finishes and intricate shapes (jig grinder).

Purpose and Applications of Jig Bore Machines

Jig bore machines specialize in high-precision hole placement and alignment, essential for tool and die making, molds, and fixtures where exact tolerances are critical. These machines excel in creating accurate hole patterns with fine positional accuracy, typically used in industries requiring intricate assembly or component fitting. Your manufacturing process benefits from jig bore machines when the main goal is ensuring perfect alignment and repeatable precision in complex parts.

Purpose and Applications of Jig Grinders

Jig grinders are precision machines designed primarily for grinding complex holes and intricate shapes with high accuracy, commonly used in die making and tool manufacturing. They excel in finishing operations requiring tight tolerances, such as machining small holes, slots, and contours that jigs or templates dictate. Unlike jig bores, which are mainly for accurate drilling and boring, jig grinders provide finer surface finishes and can handle complex geometries essential for high-precision tooling applications.

Precision and Accuracy Comparison

Jig bores achieve high precision by utilizing specialized bushings and adjustable tooling, ideal for repetitive hole locating with tolerances typically within 0.001 inches. Jig grinders offer superior accuracy through high-speed spindles and fine abrasive grinding, capable of achieving tolerances as tight as 0.0001 inches for complex surface finishing and intricate hole shapes. The choice depends on the required precision level, with jig grinders preferred for ultra-fine accuracy and jig bores suited for high-volume, consistent hole placement.

Machining Processes: Drilling vs Grinding

Jig bores excel in precision drilling by accurately enlarging holes to exact diameters using a boring head with fine adjustments, making them ideal for high-tolerance hole finishing. Jig grinders specialize in grinding processes, employing a high-speed spindle with abrasive wheels to achieve superior surface finishes and tight geometric tolerances on complex contours and holes. The key difference lies in machining processes: jig boring focuses on controlled material removal through drilling, while jig grinding uses abrasive grinding for fine surface and dimensional accuracy.

Tooling and Workholding Requirements

Jig bore machines require precise, specialized tooling such as fine feed mechanisms and interchangeable boring heads to achieve exact hole placement and size, while jig grinders utilize fine grinding spindles and abrasive grinding attachments for surface finishing and contour shaping. Workholding for jig bores typically involves rigid, accurately located fixtures to maintain hole alignment and spacing, contrasting with jig grinders that often use flexible and adjustable clamps or magnetic chucks to accommodate complex shapes and delicate surfaces. Both tools demand stable setups to minimize vibration and ensure dimensional accuracy, but the tooling and workholding solutions are specifically tailored to their distinct machining processes.

Materials Best Suited for Jig Bores vs Jig Grinders

Jig bores excel in machining softer metals such as aluminum, brass, and mild steel due to their high precision and rigidity. Jig grinders are optimized for harder materials like tool steels and hardened alloys, enabling ultra-fine surface finishes and tight tolerances. Selecting the appropriate tool depends on the material hardness and the required finish, with jig grinders preferred for extreme precision in tough materials.

Advantages and Limitations of Each Machine

Jig bores offer precise hole positioning and high repeatability, making them ideal for large production runs requiring consistent hole alignment with minimal setup time. Jig grinders excel in finishing complex contours and fine surface textures, providing superior accuracy for small, intricate features but often requiring longer cycle times and expert operation. Your choice depends on whether you prioritize fast, repetitive drilling with moderate complexity or refined, detailed grinding for high-precision applications.

Choosing the Right Machine for Your Workshop

Jig bore machines excel in precision hole making and alignment tasks, offering accuracy up to 0.001 mm suitable for tool and die makers. Jig grinders provide superior surface finishing and contour grinding with precision typically within 0.002 mm, ideal for complex shapes and fine detailing. Your workshop's choice depends on whether hole accuracy or surface finish quality is paramount for your machining projects.

Jig bore vs jig grinder Infographic

libmatt.com

libmatt.com