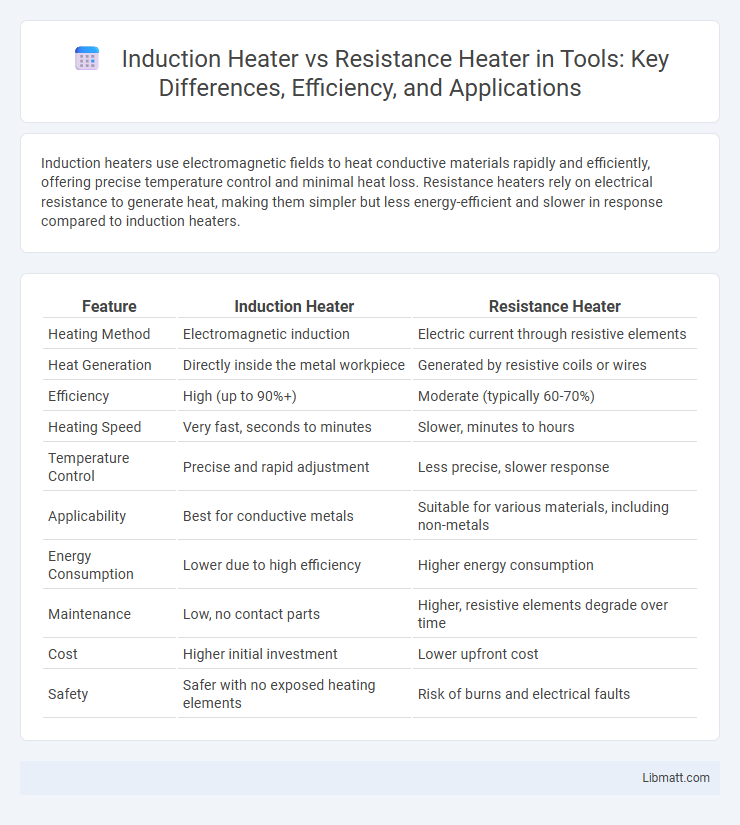

Induction heaters use electromagnetic fields to heat conductive materials rapidly and efficiently, offering precise temperature control and minimal heat loss. Resistance heaters rely on electrical resistance to generate heat, making them simpler but less energy-efficient and slower in response compared to induction heaters.

Table of Comparison

| Feature | Induction Heater | Resistance Heater |

|---|---|---|

| Heating Method | Electromagnetic induction | Electric current through resistive elements |

| Heat Generation | Directly inside the metal workpiece | Generated by resistive coils or wires |

| Efficiency | High (up to 90%+) | Moderate (typically 60-70%) |

| Heating Speed | Very fast, seconds to minutes | Slower, minutes to hours |

| Temperature Control | Precise and rapid adjustment | Less precise, slower response |

| Applicability | Best for conductive metals | Suitable for various materials, including non-metals |

| Energy Consumption | Lower due to high efficiency | Higher energy consumption |

| Maintenance | Low, no contact parts | Higher, resistive elements degrade over time |

| Cost | Higher initial investment | Lower upfront cost |

| Safety | Safer with no exposed heating elements | Risk of burns and electrical faults |

Introduction to Induction and Resistance Heaters

Induction heaters utilize electromagnetic fields to directly heat conductive materials, offering rapid and precise temperature control ideal for metal processing and heat treatment applications. Resistance heaters, on the other hand, generate heat through electrical resistance within a resistive element, providing uniform and steady heat suitable for industrial ovens and household appliances. Both heating methods serve distinct purposes based on efficiency, speed, and temperature distribution requirements in various engineering and manufacturing processes.

How Induction Heaters Work

Induction heaters generate heat through electromagnetic induction, creating eddy currents within a conductive material, which rapidly heats the object without direct contact. Unlike resistance heaters that rely on electrical resistance within a heating element to produce heat, induction heaters offer precise temperature control and faster heating times. Your choice of an induction heater ensures higher energy efficiency and reduced heat loss compared to traditional resistance heating methods.

How Resistance Heaters Work

Resistance heaters operate by passing an electric current through a resistive material, converting electrical energy into heat due to the material's inherent resistance. The generated heat is transferred directly to the surrounding environment or objects through conduction, convection, or radiation. These heaters are commonly made with elements like nichrome wire, which efficiently resist electrical flow, producing consistent and controllable heat output.

Energy Efficiency Comparison

Induction heaters convert electrical energy directly into heat within the metal workpiece through electromagnetic induction, resulting in energy efficiency rates typically between 80% to 90%. Resistance heaters generate heat by passing current through a resistive element, often exhibiting lower efficiency around 60% to 70% due to heat loss through conduction, convection, and radiation. Induction heating minimizes energy waste by targeting the material directly, making it more energy-efficient than traditional resistance heating in industrial applications.

Heating Speed and Responsiveness

Induction heaters generate heat directly in the metal through electromagnetic fields, resulting in much faster heating speeds and precise temperature control compared to resistance heaters. Resistance heaters rely on conductive elements that heat up gradually, causing slower response times and less efficient heat transfer. Your choice of heating technology should prioritize induction heating for applications requiring rapid thermal cycling and tight temperature control.

Temperature Control and Precision

Induction heaters offer superior temperature control and precision due to their rapid response time and ability to focus heat directly on the metal workpiece, allowing for accurate and consistent heating. Resistance heaters, while effective for uniform heating, often have slower response times and less precise temperature regulation due to reliance on conduction through the heating element. The electromagnetic field in induction heating enables precise adjustments and localized heating, making it ideal for applications requiring exact temperature management.

Application Suitability

Induction heaters excel in applications requiring rapid, precise, and localized heating, such as metal hardening, brazing, and forging, where minimal heat loss and energy efficiency are critical. Resistance heaters are better suited for uniform heating tasks like plastic molding, food processing, and laboratory experiments, where consistent temperature distribution is essential. Your choice depends on the specific heating requirements, material compatibility, and process speed needed for optimal performance.

Installation and Maintenance Requirements

Induction heaters require precise installation involving coil positioning and power supply calibration, which demands technical expertise, while resistance heaters offer simpler installation with straightforward wiring and minimal setup. Maintenance of induction heaters is generally lower due to the lack of direct contact heating elements, reducing wear and component replacement frequency compared to resistance heaters that experience element degradation over time and need regular inspection for corrosion or burnout. Resistance heaters typically incur higher long-term maintenance costs due to frequent element replacements and safety checks, whereas induction heaters benefit from longer operational life and reduced maintenance intervals.

Safety Aspects

Induction heaters offer enhanced safety by generating heat through electromagnetic fields, reducing the risk of burns and fire hazards associated with exposed heating elements found in resistance heaters. The non-contact heating mechanism minimizes accidental contact with hot surfaces, lowering the chance of injury. Resistance heaters, relying on direct contact heating elements, pose higher risks of overheating, electrical faults, and burns without proper safeguards.

Cost Analysis and ROI

Induction heaters typically have a higher upfront cost compared to resistance heaters due to advanced technology and specialized components, but they offer significant energy savings and faster heating cycles that enhance long-term cost efficiency. Resistance heaters generally have a lower initial purchase price but incur higher operational costs over time due to greater energy consumption and longer heating durations. The return on investment (ROI) for induction heaters is usually faster in industrial applications with high-volume or continuous heating needs, where improved efficiency and reduced maintenance costs yield substantial financial benefits.

Induction heater vs resistance heater Infographic

libmatt.com

libmatt.com