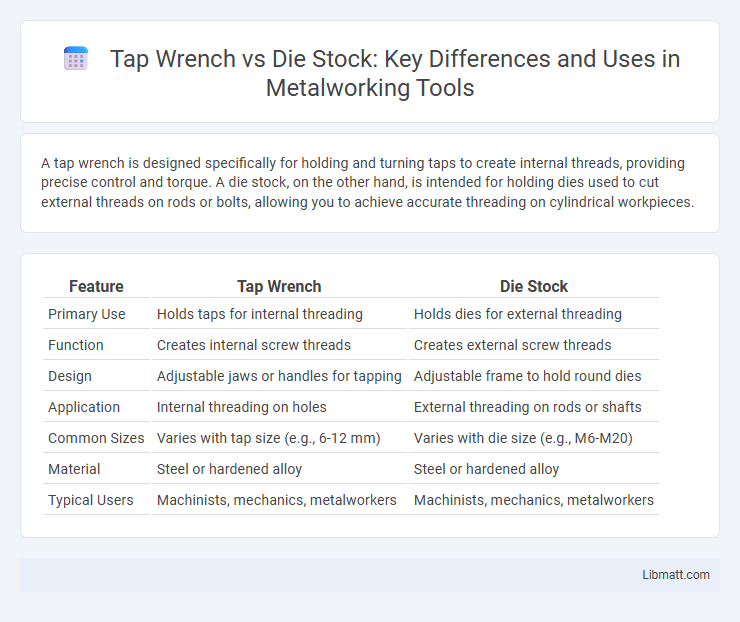

A tap wrench is designed specifically for holding and turning taps to create internal threads, providing precise control and torque. A die stock, on the other hand, is intended for holding dies used to cut external threads on rods or bolts, allowing you to achieve accurate threading on cylindrical workpieces.

Table of Comparison

| Feature | Tap Wrench | Die Stock |

|---|---|---|

| Primary Use | Holds taps for internal threading | Holds dies for external threading |

| Function | Creates internal screw threads | Creates external screw threads |

| Design | Adjustable jaws or handles for tapping | Adjustable frame to hold round dies |

| Application | Internal threading on holes | External threading on rods or shafts |

| Common Sizes | Varies with tap size (e.g., 6-12 mm) | Varies with die size (e.g., M6-M20) |

| Material | Steel or hardened alloy | Steel or hardened alloy |

| Typical Users | Machinists, mechanics, metalworkers | Machinists, mechanics, metalworkers |

Introduction to Tap Wrenches and Die Stocks

Tap wrenches and die stocks are essential hand tools used in threading operations, with tap wrenches designed to hold and turn taps for cutting internal threads, while die stocks secure dies for cutting external threads. Both tools provide precise control and leverage, allowing you to create accurate threads on metal, plastic, or wood surfaces. Understanding the specific function of each tool helps in selecting the right one for threading tasks, ensuring efficient and clean results in machining or repair work.

What is a Tap Wrench?

A tap wrench is a hand tool designed to hold and turn taps for cutting internal threads in holes. It typically features a long, adjustable handle with a chuck or jaw mechanism to secure various sizes of taps. Unlike die stocks, which are used for external threading, tap wrenches are specifically made for precision threading inside drilled holes in metals or plastics.

What is a Die Stock?

A die stock is a hand tool designed to hold and turn circular dies for cutting external threads on rods or bolts. It provides leverage and stability, allowing precise thread formation essential for mechanical and plumbing applications. Your choice between a tap wrench and a die stock depends on whether you need to create internal or external threads.

Key Functions of Tap Wrenches

Tap wrenches are specifically designed to hold and turn taps for threading internal holes with precision and control. Their long handles provide the necessary torque and stability to create accurate threads without damaging the workpiece. If you need to thread holes efficiently, your tap wrench offers superior grip and maneuverability compared to other tools like die stocks.

Primary Uses of Die Stocks

Die stocks are primarily used for holding and turning threading dies to cut or repair external threads on rods and bolts, ensuring precise and consistent thread formations. They provide a firm grip and better control for manual threading compared to tap wrenches, which are designed mainly for internal threading with taps. Their robust design allows handling larger dies and applying uniform pressure, making them essential for external thread creation in metalworking and mechanical repairs.

Design Differences: Tap Wrench vs Die Stock

Tap wrenches feature a T-shaped handle with an adjustable jaw designed specifically to hold taps securely for threading internal holes, while die stocks consist of a round or hexagonal handle with a central collet to grip dies used for cutting external threads on rods or bolts. The tap wrench's compact, adjustable grip allows controlled torque application in confined spaces, whereas die stocks provide a sturdier, symmetrical grip to evenly distribute pressure during cutting. Understanding these design differences helps Your tool selection for precise and efficient threading tasks.

Advantages of Using Tap Wrenches

Tap wrenches provide greater control and precision when threading internal surfaces, allowing for smoother and more accurate cuts compared to die stocks. Their adjustable jaws accommodate various tap sizes, enhancing versatility and reducing the need for multiple tools. Ergonomic handles improve grip and torque application, minimizing user fatigue during extended threading tasks.

Benefits of Using Die Stocks

Die stocks offer precise control for threading tasks, ensuring cleaner and more accurate threads compared to tap wrenches. Their ergonomic design reduces hand fatigue during extended use, making them ideal for intricate metalworking projects. Using a die stock enhances your ability to create uniform external threads, improving the overall quality of your machining work.

Choosing Between Tap Wrench and Die Stock

Choosing between a tap wrench and die stock depends primarily on the type of threading task you need to perform. A tap wrench is designed to hold and turn taps for internal threading, while a die stock is specifically used for external threading with dies. Your decision should be based on whether you need to create internal threads in holes or external threads on rods and bolts.

Conclusion: Tap Wrench vs Die Stock Summary

A tap wrench is specifically designed to hold and turn taps for threading internal holes, providing precise control in smaller diameter operations. A die stock, on the other hand, grips dies used to cut external threads on rods or bolts, offering stability for various thread sizes. Choosing between a tap wrench and die stock depends on whether internal threading or external threading is required for the machining task.

Tap wrench vs die stock Infographic

libmatt.com

libmatt.com