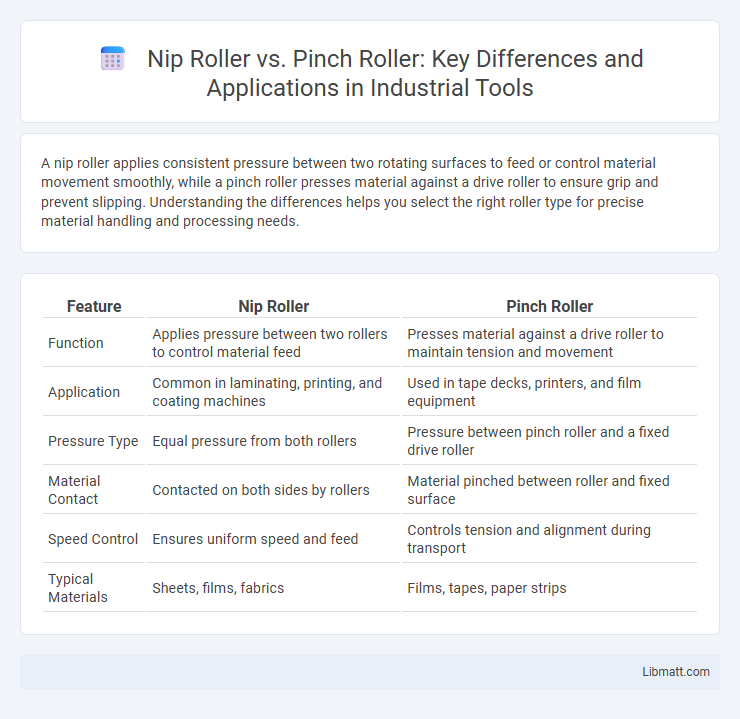

A nip roller applies consistent pressure between two rotating surfaces to feed or control material movement smoothly, while a pinch roller presses material against a drive roller to ensure grip and prevent slipping. Understanding the differences helps you select the right roller type for precise material handling and processing needs.

Table of Comparison

| Feature | Nip Roller | Pinch Roller |

|---|---|---|

| Function | Applies pressure between two rollers to control material feed | Presses material against a drive roller to maintain tension and movement |

| Application | Common in laminating, printing, and coating machines | Used in tape decks, printers, and film equipment |

| Pressure Type | Equal pressure from both rollers | Pressure between pinch roller and a fixed drive roller |

| Material Contact | Contacted on both sides by rollers | Material pinched between roller and fixed surface |

| Speed Control | Ensures uniform speed and feed | Controls tension and alignment during transport |

| Typical Materials | Sheets, films, fabrics | Films, tapes, paper strips |

Introduction to Nip Rollers and Pinch Rollers

Nip rollers consist of two or more rollers arranged closely to exert consistent pressure on materials like paper, film, or fabric during processing. Pinch rollers function by pressing material against a single roller or drum, controlling the movement and tension in applications such as printing and laminating. Both rollers play crucial roles in manufacturing lines, ensuring precise material handling and tension control.

Key Differences Between Nip Rollers and Pinch Rollers

Nip rollers apply precise pressure across a material's width using two rollers pressed together, optimizing uniform thickness and smooth surface finish in processes like printing and lamination. Pinch rollers, by contrast, only grip and guide the material by pressing it against a fixed surface or another roller, ensuring controlled material movement rather than thickness control. The key difference lies in nip rollers' role in compression and thickness regulation, while pinch rollers primarily manage material feeding and alignment within machinery.

How Nip Rollers Work

Nip rollers work by applying consistent pressure between two rotating cylinders to control material tension and thickness during processing. The precise gap between the rollers ensures uniform compression, essential for laminating, coating, or printing applications. Unlike pinch rollers that primarily guide and feed material, nip rollers actively regulate product characteristics through controlled pressure.

How Pinch Rollers Operate

Pinch rollers operate by applying pressure to material passing between themselves and a drive roller, ensuring consistent grip and movement during processes like printing or laminating. Their precise pressure control prevents slippage and maintains tension, crucial for accurate material handling. Unlike nip rollers, which evenly compress materials between two rollers, pinch rollers primarily focus on controlling speed and feed through friction-based contact.

Typical Industrial Applications

Nip rollers are commonly used in industrial applications requiring precise control of material tension, such as printing presses, laminating machines, and packaging lines, where consistent contact and pressure ensure accurate material handling. Pinch rollers are ideal for applications involving feeding or guiding flexible materials like film, foil, or paper through machinery, frequently found in textile manufacturing and film coating processes. Your choice between nip and pinch rollers depends on the specific tension control and material handling needs of your industrial process.

Advantages of Nip Rollers

Nip rollers provide precise control over material tension and alignment, reducing slippage and improving accuracy in processing lines. Their design allows for consistent pressure distribution, which minimizes material deformation and enhances product quality. You benefit from increased efficiency and reduced downtime when using nip rollers compared to pinch rollers, especially in applications requiring gentle handling of sensitive substrates.

Benefits of Pinch Rollers

Pinch rollers provide precise control of material tension and alignment during processing, reducing slippage and enhancing product quality in manufacturing lines. They enable smooth, consistent feeding of web materials such as films, papers, and textiles, contributing to improved process efficiency and reduced downtime. Pinch rollers also accommodate various material thicknesses, offering versatile application across industries including printing, packaging, and converting.

Material Compatibility and Performance

Nip rollers and pinch rollers differ significantly in material compatibility and performance, with nip rollers offering superior control for delicate or thin materials due to their even pressure distribution. Pinch rollers excel in handling flexible or thicker materials, providing strong grip and consistent feed without slippage. Understanding these differences helps optimize your equipment choice for specific material types and production quality.

Factors to Consider When Choosing

When selecting between a nip roller and a pinch roller, consider factors such as the material type, thickness, and tension requirements to ensure optimal grip and control. Nip rollers provide uniform pressure ideal for delicate or flexible materials, while pinch rollers are better suited for precise feeding and guiding applications involving heavier or stiffer media. Your choice should align with the specific application's speed, pressure distribution, and durability needs to maximize performance and reduce wear.

Conclusion: Nip Roller vs Pinch Roller

Nip rollers provide precise pressure and alignment for materials in processes like printing and laminating, ensuring consistent results. Pinch rollers primarily guide or feed materials by applying moderate pressure without the same level of control or accuracy as nip rollers. Your choice between a nip roller and a pinch roller depends on the required pressure control and application precision.

Nip roller vs pinch roller Infographic

libmatt.com

libmatt.com