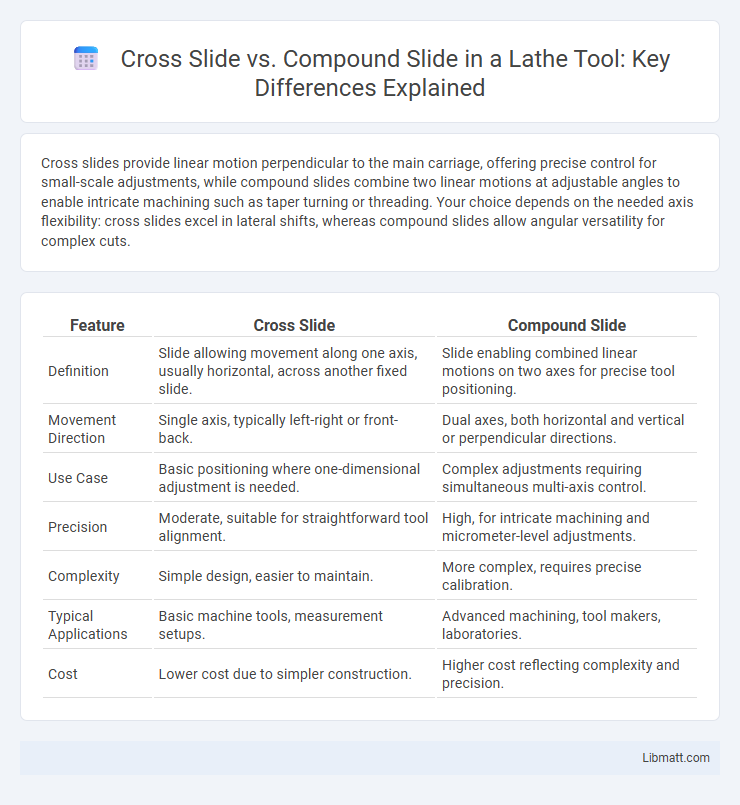

Cross slides provide linear motion perpendicular to the main carriage, offering precise control for small-scale adjustments, while compound slides combine two linear motions at adjustable angles to enable intricate machining such as taper turning or threading. Your choice depends on the needed axis flexibility: cross slides excel in lateral shifts, whereas compound slides allow angular versatility for complex cuts.

Table of Comparison

| Feature | Cross Slide | Compound Slide |

|---|---|---|

| Definition | Slide allowing movement along one axis, usually horizontal, across another fixed slide. | Slide enabling combined linear motions on two axes for precise tool positioning. |

| Movement Direction | Single axis, typically left-right or front-back. | Dual axes, both horizontal and vertical or perpendicular directions. |

| Use Case | Basic positioning where one-dimensional adjustment is needed. | Complex adjustments requiring simultaneous multi-axis control. |

| Precision | Moderate, suitable for straightforward tool alignment. | High, for intricate machining and micrometer-level adjustments. |

| Complexity | Simple design, easier to maintain. | More complex, requires precise calibration. |

| Typical Applications | Basic machine tools, measurement setups. | Advanced machining, tool makers, laboratories. |

| Cost | Lower cost due to simpler construction. | Higher cost reflecting complexity and precision. |

Introduction to Cross Slide and Compound Slide

A cross slide is a machine tool component allowing precise lateral movement perpendicular to the main slide, primarily used in lathes for adjusting the cutting tool's position. A compound slide offers angular adjustment capability in addition to linear movement, enabling complex taper cuts or precise tool positioning at various angles. Understanding the difference between your cross slide and compound slide can optimize machining accuracy and efficiency.

Key Differences Between Cross Slide and Compound Slide

The key differences between a cross slide and a compound slide lie in their movement and function: a cross slide moves strictly perpendicular to the lathe bed, enabling precise lateral adjustments, while a compound slide pivots at an angle, allowing for angular cuts and taper turning. Cross slides provide straightforward linear motion, essential for facing operations, whereas compound slides facilitate more complex machining tasks such as threading and chamfering due to their angled positioning. Understanding these distinctions helps you select the appropriate slide for specific turning and cutting operations on a lathe.

Design and Structure Comparison

The cross slide features a simple design with a single-stage platform that moves perpendicularly to the primary slide, offering precise adjustments mainly in one axis for tool positioning. In contrast, the compound slide combines two dovetail slides arranged at adjustable angles, allowing for both linear and angular movements, which enhances versatility in cutting operations. Your choice depends on whether you require straightforward, precise linear control (cross slide) or multifaceted positioning and angular adjustments (compound slide) in your machining tasks.

Functions and Applications

The cross slide is designed for precise lateral movement of a workpiece, primarily used in milling and drilling applications to enable accurate positioning along one axis. The compound slide offers angular adjustments in addition to linear movement, making it essential for taper turning and intricate machining tasks requiring multi-directional control. Your choice between these slides depends on the complexity of the operation and the level of precision needed in shaping or drilling components.

Advantages of Cross Slide

The cross slide offers precise lateral movement, enabling accurate positioning in machining tasks. Its simple design reduces setup time and maintenance compared to compound slides, enhancing operational efficiency. You benefit from improved stability and better control when performing straight cuts or adjustments with a cross slide.

Advantages of Compound Slide

Compound slides offer enhanced precision and versatility compared to cross slides, allowing simultaneous movement along two axes with greater control. Their design enables finer adjustments for complex machining tasks, improving accuracy in operations like turning and threading. These features contribute to increased efficiency and superior surface finishes in metalworking processes.

Limitations and Drawbacks

The cross slide has limitations in only allowing linear movement along two perpendicular axes, which restricts complex machining operations and precision. The compound slide offers adjustable angular movement, but its drawbacks include increased complexity, higher setup time, and potential for reduced rigidity compared to the cross slide. Both slides may suffer from wear and play over time, impacting accuracy and requiring frequent maintenance.

Choosing the Right Slide for Your Lathe

Choosing the right slide for your lathe depends on the type of machining precision and flexibility you require. A cross slide offers straightforward movement perpendicular to the lathe bed, ideal for simple facing and turning tasks, while a compound slide provides angular adjustment for complex cuts like tapers and chamfers. Understanding your machining needs will help you select the appropriate slide, enhancing your lathe's functionality and machining accuracy.

Maintenance and Durability Factors

Cross slides require frequent lubrication and adjustment due to their perpendicular movement, which can lead to increased wear if neglected. Compound slides, with their angular adjustment capability, often experience stress at the pivot points, necessitating regular inspection for loosening or damage. Both slide types benefit from corrosion-resistant materials and dust-proof seals to enhance durability and reduce maintenance intervals.

Conclusion: Which Slide is Best for Your Needs

Cross slides provide precise lateral movement ideal for machining tasks requiring fine adjustments, while compound slides offer versatile angular positioning suited for taper cutting and detailed shaping. Selecting the best slide depends on your specific application: choose a cross slide for straightforward horizontal travel and a compound slide when multiple axis control enhances accuracy and functionality. Evaluate the complexity of your workpiece and desired motion to determine the most effective slide system for optimal machining performance.

Cross slide vs compound slide Infographic

libmatt.com

libmatt.com