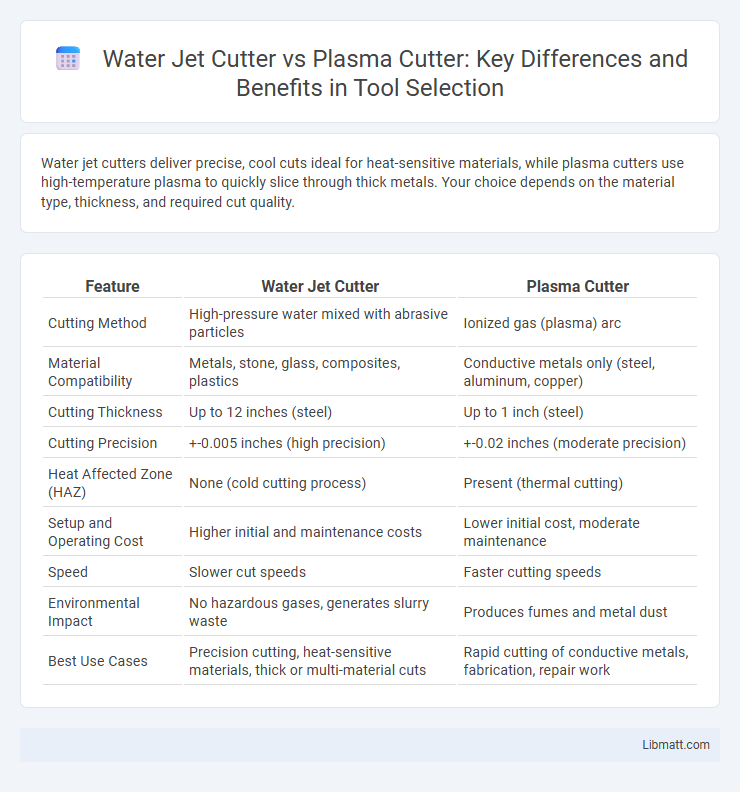

Water jet cutters deliver precise, cool cuts ideal for heat-sensitive materials, while plasma cutters use high-temperature plasma to quickly slice through thick metals. Your choice depends on the material type, thickness, and required cut quality.

Table of Comparison

| Feature | Water Jet Cutter | Plasma Cutter |

|---|---|---|

| Cutting Method | High-pressure water mixed with abrasive particles | Ionized gas (plasma) arc |

| Material Compatibility | Metals, stone, glass, composites, plastics | Conductive metals only (steel, aluminum, copper) |

| Cutting Thickness | Up to 12 inches (steel) | Up to 1 inch (steel) |

| Cutting Precision | +-0.005 inches (high precision) | +-0.02 inches (moderate precision) |

| Heat Affected Zone (HAZ) | None (cold cutting process) | Present (thermal cutting) |

| Setup and Operating Cost | Higher initial and maintenance costs | Lower initial cost, moderate maintenance |

| Speed | Slower cut speeds | Faster cutting speeds |

| Environmental Impact | No hazardous gases, generates slurry waste | Produces fumes and metal dust |

| Best Use Cases | Precision cutting, heat-sensitive materials, thick or multi-material cuts | Rapid cutting of conductive metals, fabrication, repair work |

Introduction to Water Jet and Plasma Cutters

Water jet cutters utilize high-pressure water mixed with abrasive materials to precisely cut through metals, stone, and composites without generating heat, preserving material integrity. Plasma cutters employ ionized gas at extremely high temperatures to melt and blow away metal, offering fast and efficient cutting, especially for electrically conductive materials. Your choice between these tools depends on the required precision, material type, and thickness.

How Water Jet Cutters Work

Water jet cutters operate by propelling a high-pressure stream of water, sometimes mixed with abrasive materials, to precisely erode and cut through various materials such as metal, stone, and glass. The water pressure can reach up to 60,000 psi, allowing for clean cuts without generating heat, which prevents material distortion and preserves structural integrity. This cold cutting process is especially beneficial for materials sensitive to high temperatures, offering superior precision and minimal kerf compared to thermal cutting methods like plasma cutters.

How Plasma Cutters Work

Plasma cutters operate by generating an electrical arc through a gas, such as compressed air, which turns into plasma at extremely high temperatures, capable of melting metal quickly. The plasma jet is directed through a small nozzle, allowing for precise and rapid cutting of electrically conductive materials like steel, aluminum, and copper. This method is particularly effective for cutting thick metals, offering fast processing speeds and minimal heat distortion compared to traditional cutting techniques.

Material Compatibility: Water Jet vs Plasma Cutter

Water jet cutters excel in cutting a wide range of materials, including metals, glass, stone, ceramics, and composites, without causing thermal distortion due to their cold cutting process. Plasma cutters are primarily effective for conductive metals such as steel, stainless steel, aluminum, and copper, leveraging high-temperature plasma to slice through thick metal sheets quickly. While water jet cutting provides greater versatility and precision on diverse materials, plasma cutting offers faster, cost-effective solutions for metal fabrication tasks.

Cut Quality and Precision Comparison

Water jet cutters deliver superior cut quality and precision by using high-pressure water mixed with abrasive materials, enabling smooth edges and minimal heat-affected zones ideal for intricate designs. Plasma cutters operate at high temperatures that can cause slight distortion and rougher edges, making them less precise for detailed work but faster for thicker metals. Your choice depends on the importance of precision versus speed, with water jet cutters excelling in accuracy and plasma cutters offering efficiency on tougher materials.

Speed and Efficiency Analysis

Water jet cutters deliver precise cuts on a wide range of materials without heat distortion, but generally operate slower than plasma cutters, which excel in speed for cutting thick, conductive metals. Plasma cutters offer higher cutting speeds and lower operating costs for metal fabrication, making them efficient for high-volume industrial applications. Your choice depends on whether precision and material versatility or rapid cutting and cost efficiency are more critical for your project.

Operating Costs and Maintenance

Water jet cutters typically have higher operating costs due to the expense of abrasive materials and water filtration systems, but they require less frequent maintenance compared to plasma cutters. Plasma cutters consume more electricity and replaceable consumables like electrodes and nozzles regularly, increasing maintenance needs and operating expenditures. Your choice depends on balancing upfront costs with long-term maintenance efficiency in the intended cutting environment.

Safety Considerations for Both Technologies

Water jet cutters operate at high pressures and require proper protective gear to prevent injuries from water and abrasive materials, while plasma cutters generate intense heat and UV light, necessitating flame-resistant clothing and eye protection. Both technologies demand adequate ventilation to avoid inhalation of harmful fumes or particles. Ensuring your workspace follows safety protocols can significantly reduce risks associated with these powerful cutting tools.

Environmental Impact and Waste Management

Water jet cutters produce minimal heat and toxic fumes, resulting in lower environmental pollution compared to plasma cutters, which emit smoke and gases requiring filtration. The abrasive materials used in water jets can often be recycled or disposed of safely, whereas plasma cutting generates slag and metal dust that need specialized handling to prevent environmental contamination. Your choice between these technologies influences waste management practices and overall ecological footprint in manufacturing processes.

Choosing the Right Cutter for Your Application

Water jet cutters provide precise, cold cutting ideal for heat-sensitive materials such as aluminum, titanium, and composites, making them perfect for detailed fabrication and automotive parts. Plasma cutters excel in cutting thick metals rapidly, offering cost-effective performance for industrial steel and stainless steel applications. Selecting between the two depends on material type, thickness, desired edge quality, and budget constraints, with water jets suited for intricate designs and plasma cutters preferred for heavy-duty metal cutting.

Water jet cutter vs plasma cutter Infographic

libmatt.com

libmatt.com