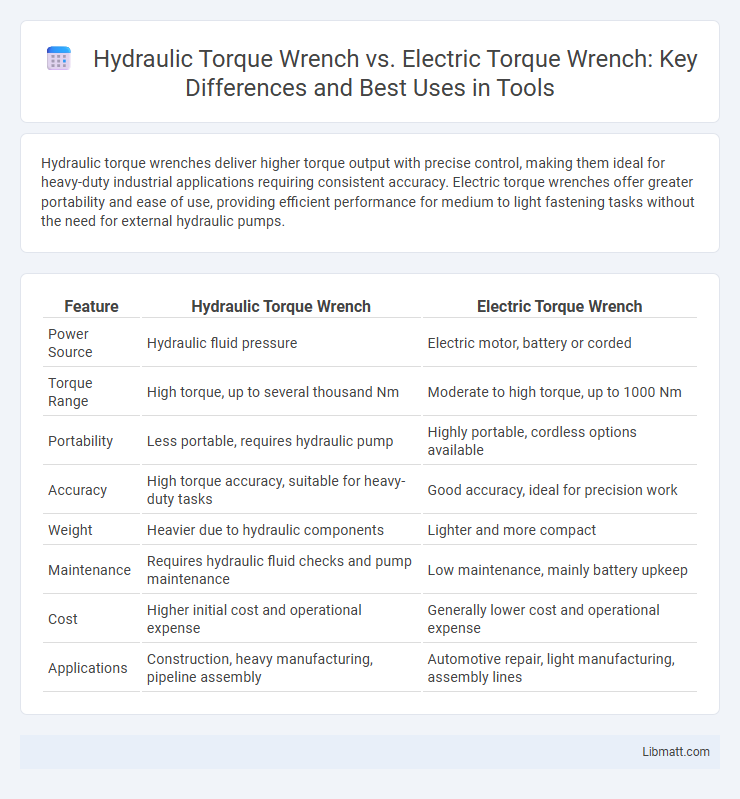

Hydraulic torque wrenches deliver higher torque output with precise control, making them ideal for heavy-duty industrial applications requiring consistent accuracy. Electric torque wrenches offer greater portability and ease of use, providing efficient performance for medium to light fastening tasks without the need for external hydraulic pumps.

Table of Comparison

| Feature | Hydraulic Torque Wrench | Electric Torque Wrench |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Electric motor, battery or corded |

| Torque Range | High torque, up to several thousand Nm | Moderate to high torque, up to 1000 Nm |

| Portability | Less portable, requires hydraulic pump | Highly portable, cordless options available |

| Accuracy | High torque accuracy, suitable for heavy-duty tasks | Good accuracy, ideal for precision work |

| Weight | Heavier due to hydraulic components | Lighter and more compact |

| Maintenance | Requires hydraulic fluid checks and pump maintenance | Low maintenance, mainly battery upkeep |

| Cost | Higher initial cost and operational expense | Generally lower cost and operational expense |

| Applications | Construction, heavy manufacturing, pipeline assembly | Automotive repair, light manufacturing, assembly lines |

Introduction to Hydraulic and Electric Torque Wrenches

Hydraulic torque wrenches use pressurized fluid to generate high torque with precision, making them ideal for heavy-duty industrial applications requiring controlled force and safety. Electric torque wrenches rely on battery-powered motors to deliver consistent torque output, offering portability and ease of use for lighter to medium fastening tasks. Your choice between hydraulic and electric torque wrenches depends on the required torque range, workspace constraints, and maintenance preferences.

How Hydraulic Torque Wrenches Work

Hydraulic torque wrenches use pressurized fluid to generate precise torque, delivering high force through a compact design that ensures consistent and repeatable tightening. The hydraulic system powers a piston that drives the wrench's reaction arm, allowing for controlled application on heavy-duty bolts often found in industrial settings. Your choice of a hydraulic torque wrench ensures accuracy and safety when working with exceptionally tight fasteners in demanding environments.

How Electric Torque Wrenches Operate

Electric torque wrenches operate using a motor that drives the wrench mechanism to apply precise torque to fasteners, ensuring consistent and repeatable tightening. These tools incorporate electronic controls and sensors to monitor torque levels, delivering accurate results ideal for applications requiring stringent torque specifications. The compact design and battery-powered operation provide enhanced portability and ease of use compared to hydraulic systems.

Key Differences Between Hydraulic and Electric Torque Wrenches

Hydraulic torque wrenches deliver high torque output through fluid pressure, making them ideal for heavy-duty industrial applications requiring precise and powerful fastening. Electric torque wrenches use electric motors for torque generation, offering portability, ease of use, and digital control features suited for lighter to medium-duty tasks. Your choice depends on the torque requirements, operational environment, and the need for accuracy or mobility in fastening operations.

Torque Accuracy and Calibration Comparison

Hydraulic torque wrenches offer superior torque accuracy, typically within +-3%, due to their precise hydraulic pressure control and minimal torque loss during operation. Electric torque wrenches generally provide accuracy levels around +-5%, relying on electronic sensors that can be affected by battery conditions and calibration drift. Calibration for hydraulic wrenches involves pressure gauge verification and fluid consistency checks, while electric wrenches require periodic software updates and sensor recalibration to maintain torque precision.

Applications and Industries for Each Type

Hydraulic torque wrenches are widely used in heavy industries such as oil and gas, construction, and manufacturing, where high torque accuracy and power are essential for tightening large bolts in pipelines, heavy machinery, and structural assemblies. Electric torque wrenches are preferred in automotive, aerospace, and maintenance sectors due to their portability, ease of use, and precision for smaller to medium torque applications like engine assembly, aircraft maintenance, and equipment servicing. Both tools serve critical roles in industries requiring reliable torque control but differ in their suitability based on torque range and operational demands.

Portability and Power Source Considerations

Hydraulic torque wrenches offer superior power output and precision, ideal for heavy-duty applications but require an external hydraulic pump, limiting portability. Electric torque wrenches operate on rechargeable batteries, enhancing mobility and ease of use in remote or confined spaces, though they typically provide less torque compared to hydraulic models. Selecting between these tools depends on balancing the need for high torque capacity against the convenience of cordless operation.

Safety Features and Risks

Hydraulic torque wrenches offer superior safety features with built-in pressure relief valves and reduced risk of electrical hazards, making them ideal for environments requiring explosion-proof tools. Electric torque wrenches provide ease of use and faster operation but carry risks related to electrical shock and overheating if not properly maintained. Your choice should consider the specific safety demands of your application to minimize workplace accidents and equipment damage.

Maintenance and Durability

Hydraulic torque wrenches require regular maintenance of hydraulic seals, hoses, and fluid to ensure optimal performance and prevent leaks, significantly influencing their durability in heavy-duty applications. Electric torque wrenches demand less frequent maintenance but rely on battery health and motor condition, which can degrade faster under continuous use. Your choice should consider the maintenance routines you can commit to and the expected lifespan in your specific work environment.

Choosing the Right Torque Wrench for Your Needs

Hydraulic torque wrenches deliver high torque output for heavy-duty industrial applications requiring precise bolt tension, while electric torque wrenches offer portability and ease of use for medium to light tasks with consistent accuracy. Your choice depends on the torque range, operational environment, and frequency of use, with hydraulic models suited for explosive torque demands and electric options favoring convenience and speed. Understanding these key differences ensures you select the most effective tool tailored to your specific tightening requirements.

Hydraulic torque wrench vs electric torque wrench Infographic

libmatt.com

libmatt.com