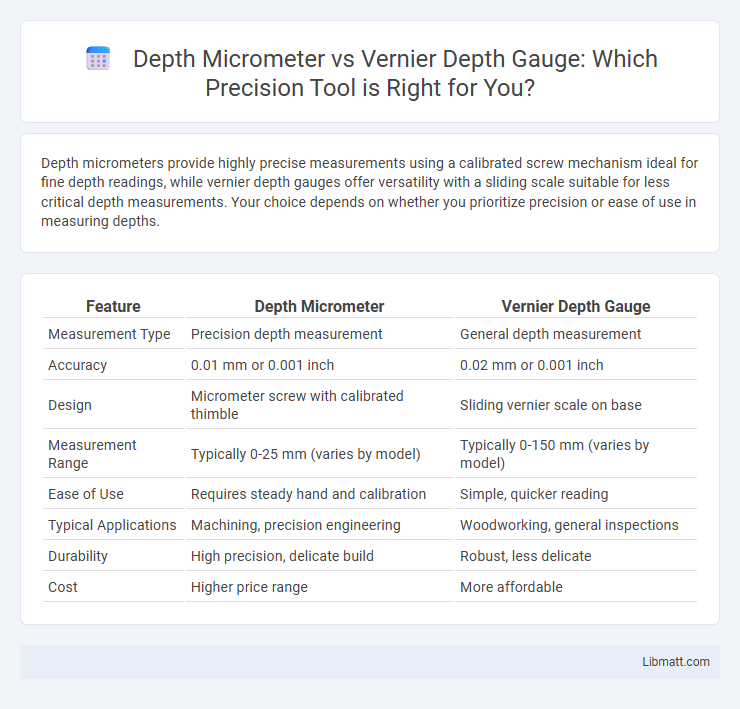

Depth micrometers provide highly precise measurements using a calibrated screw mechanism ideal for fine depth readings, while vernier depth gauges offer versatility with a sliding scale suitable for less critical depth measurements. Your choice depends on whether you prioritize precision or ease of use in measuring depths.

Table of Comparison

| Feature | Depth Micrometer | Vernier Depth Gauge |

|---|---|---|

| Measurement Type | Precision depth measurement | General depth measurement |

| Accuracy | 0.01 mm or 0.001 inch | 0.02 mm or 0.001 inch |

| Design | Micrometer screw with calibrated thimble | Sliding vernier scale on base |

| Measurement Range | Typically 0-25 mm (varies by model) | Typically 0-150 mm (varies by model) |

| Ease of Use | Requires steady hand and calibration | Simple, quicker reading |

| Typical Applications | Machining, precision engineering | Woodworking, general inspections |

| Durability | High precision, delicate build | Robust, less delicate |

| Cost | Higher price range | More affordable |

Introduction to Depth Measurement Tools

Depth micrometers provide precise depth measurements using a calibrated spindle and ratchet mechanism, ideal for applications requiring high accuracy within Micrometer Resolution ranges (0.001 mm to 0.01 mm). Vernier depth gauges offer versatility and ease of use with a graduated scale, suitable for general depth measurements in workshops and field inspections with typical accuracy around 0.02 mm. Both tools measure bore depths, slot depths, and recesses but differ in precision, design, and dial or digital readout options, affecting their application in engineering and manufacturing.

Overview of Depth Micrometers

Depth micrometers provide highly precise measurements of depths, grooves, and recesses with a spindle that moves perpendicularly to the base. They typically feature a screw mechanism and interchangeable rods calibrated in microns, allowing for accurate readings up to 0.001 mm or 0.0001 inches. Compared to vernier depth gauges, depth micrometers deliver enhanced accuracy for fine machining and inspection tasks important for your quality control processes.

Overview of Vernier Depth Gauges

Vernier depth gauges provide precise depth measurements through a sliding scale with a fine vernier, ideal for measuring grooves, holes, and recesses with accuracy typically up to 0.02 mm or 0.001 inches. Unlike depth micrometers, vernier depth gauges offer easier readability and quicker measurements without the need for calibration before each use. Your choice depends on the required accuracy and convenience, with vernier depth gauges being suitable for general workshop applications.

Key Components and Features

Depth micrometers feature a precision spindle and a calibrated thimble for highly accurate depth measurements, often reaching resolutions of 0.01 mm or better. Vernier depth gauges include a main scale and a sliding vernier scale, allowing manual readings with typical accuracy around 0.02 mm. Both tools have a flat base to stabilize measurements, but depth micrometers often offer enhanced precision through micrometer heads and interchangeable rods for varying depths.

Measurement Range and Accuracy

Depth micrometers typically offer higher accuracy, often reaching up to 0.001 mm, making them ideal for precise measurement tasks. Their measurement range is usually limited, commonly spanning from 0 to 25 mm, with extensions available for deeper measurements. Vernier depth gauges provide a broader measurement range, sometimes exceeding 150 mm, but sacrifice some accuracy, generally around 0.02 mm, suitable for less critical depth measurements.

Ease of Use and Readability

Depth micrometers generally offer higher precision with a clear dial or digital readout, making measurement readings easier to interpret accurately. Vernier depth gauges require careful alignment of the vernier scale, which can be more challenging for users unfamiliar with reading fine graduations. Your choice should consider whether ease of use or maximum readability during quick measurements is more critical for your application.

Applications in Various Industries

Depth micrometers provide precise depth measurements critical in manufacturing, automotive, and aerospace industries for inspecting bore depths and step heights. Vernier depth gauges offer versatile, cost-effective solutions suitable for woodworking, metalworking, and general engineering tasks requiring accurate depth readings with moderate precision. Both tools enhance quality control and dimensional accuracy tailored to specific industrial applications.

Calibration and Maintenance Requirements

Depth micrometers require precise calibration using gauge blocks or reference standards to ensure accuracy within micrometer tolerances, typically 0.001 mm, and demand regular maintenance such as cleaning and lubrication of the spindle mechanism to prevent wear. Vernier depth gauges, while less precise with typical resolutions of 0.02 mm or 0.05 mm, need periodic zero-setting and calibration against a flat reference surface to maintain measurement reliability, with simpler maintenance focusing on keeping the scale and sliding parts clean. Both tools benefit from storage in protective cases and routine inspection to avoid mechanical damage and ensure consistent calibration performance.

Cost and Availability Comparison

Depth micrometers generally cost more than vernier depth gauges due to their higher precision and specialized design, making them a larger investment for professional use. Vernier depth gauges are widely available and more affordable, suitable for general measurements where extreme accuracy is not critical. Your choice between them should balance budget constraints with the required measurement precision and availability for your specific application.

Choosing the Right Tool for Your Needs

Depth micrometers offer high precision for measuring small depths, making them ideal for tasks requiring exact measurements, while vernier depth gauges provide versatility with a wider measuring range and ease of use for varied depth measurements. Your choice depends on the required accuracy and the specific application, with depth micrometers suited for fine detail work and vernier depth gauges better for general-purpose depth measurements. Considering accuracy, range, and ease of reading will help you select the right tool for your needs.

Depth micrometer vs vernier depth gauge Infographic

libmatt.com

libmatt.com