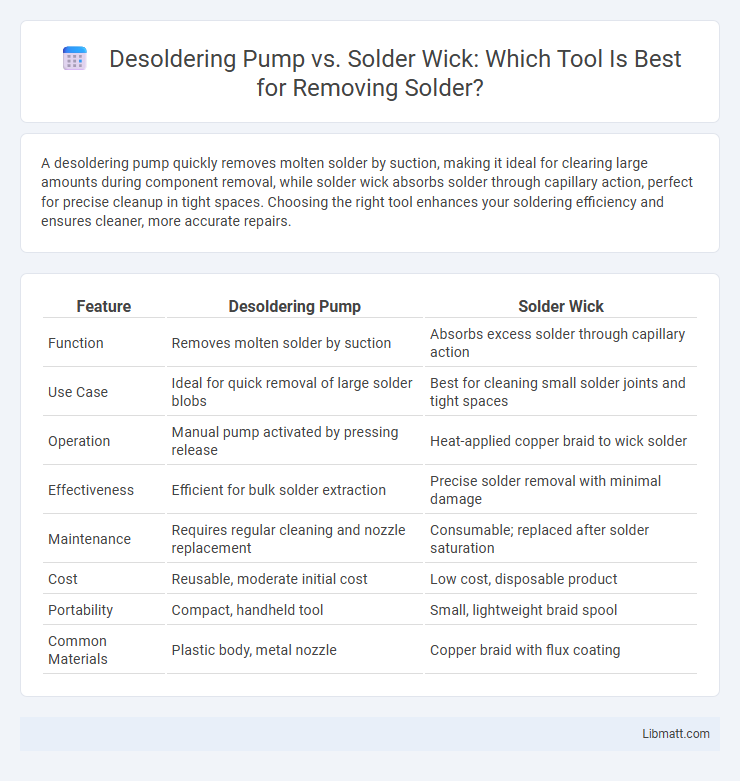

A desoldering pump quickly removes molten solder by suction, making it ideal for clearing large amounts during component removal, while solder wick absorbs solder through capillary action, perfect for precise cleanup in tight spaces. Choosing the right tool enhances your soldering efficiency and ensures cleaner, more accurate repairs.

Table of Comparison

| Feature | Desoldering Pump | Solder Wick |

|---|---|---|

| Function | Removes molten solder by suction | Absorbs excess solder through capillary action |

| Use Case | Ideal for quick removal of large solder blobs | Best for cleaning small solder joints and tight spaces |

| Operation | Manual pump activated by pressing release | Heat-applied copper braid to wick solder |

| Effectiveness | Efficient for bulk solder extraction | Precise solder removal with minimal damage |

| Maintenance | Requires regular cleaning and nozzle replacement | Consumable; replaced after solder saturation |

| Cost | Reusable, moderate initial cost | Low cost, disposable product |

| Portability | Compact, handheld tool | Small, lightweight braid spool |

| Common Materials | Plastic body, metal nozzle | Copper braid with flux coating |

Introduction to Desoldering Techniques

Desoldering techniques like using a desoldering pump or solder wick are essential for removing excess solder from electronic components. A desoldering pump offers quick, suction-based removal ideal for larger soldered joints, while solder wick provides precise absorption for tight spaces and delicate parts. Choosing the right tool enhances your efficiency and accuracy when reworking or repairing circuits.

What is a Desoldering Pump?

A desoldering pump is a handheld tool designed to quickly remove molten solder from electronic components and circuit boards, making repair or replacement easier. It works by creating a vacuum that sucks up the melted solder when you activate its plunger after heating the solder joint. Using a desoldering pump ensures precise solder removal without damaging delicate parts, improving the efficiency of your desoldering tasks.

What is Solder Wick?

Solder wick, also known as desoldering braid, is a finely woven copper mesh used to remove excess solder from electronic components during circuit repair or rework. It functions by capillary action, drawing molten solder away when heated with a soldering iron, ensuring clean and precise desoldering. If you need to clear solder from tight spots or delicate connections, solder wick offers a controlled and effective solution compared to a desoldering pump.

Key Differences Between Desoldering Pump and Solder Wick

Desoldering pumps are mechanical tools designed to quickly suction molten solder from electronic joints, offering speed and reusability for repeated solder removal tasks. Solder wicks, made of braided copper wire, absorb excess solder through capillary action, providing precision for delicate components but requiring replacement after each use. Your choice depends on the volume of solder, precision needed, and convenience, with pumps suited for larger solder amounts and wicks ideal for fine, controlled cleanup.

Pros and Cons of Using a Desoldering Pump

A desoldering pump offers rapid and efficient removal of molten solder, making it ideal for larger joints and through-hole components. Its main advantages include easy operation and quick cleanup of excess solder, but it can struggle with precision in tight spaces and small SMD components. The pump requires regular maintenance to avoid clogging and may sometimes suck up unwanted flux or board material, potentially causing damage.

Pros and Cons of Using Solder Wick

Solder wick offers precise control for removing small amounts of solder, making it ideal for delicate electronic components and minimizing damage to circuit boards. Its main drawbacks include slower removal speed and the need for frequent replacement as the copper braid becomes saturated with solder. You benefit from less risk of heat damage compared to a desoldering pump, but the process requires more patience and technique.

Best Use Cases for Desoldering Pump

Desoldering pumps excel in quickly removing large amounts of molten solder from through-hole components and circuit boards, making them ideal for repair or rework tasks involving thick leads or multiple solder joints. Their suction power efficiently clears solder without leaving residue, which is crucial for preparing pads for new component placement. Your workflow benefits from desoldering pumps when speed and thorough solder removal are priorities, especially in professional or high-volume electronics repair.

Best Use Cases for Solder Wick

Solder wick is best used for precision desoldering tasks, especially when removing excess solder from small components or tight spaces on a circuit board. It efficiently cleans solder joints without damaging pads or traces, making it ideal for delicate electronics repair. Your ability to manage solder removal with solder wick ensures cleaner rework and less risk of component damage compared to pumping methods.

Factors to Consider When Choosing a Desoldering Tool

Choosing between a desoldering pump and solder wick depends on factors such as the type of solder joints, precision required, and ease of use. Desoldering pumps excel in quickly removing large amounts of molten solder from through-hole components, while solder wick provides better control for cleaning tight spaces and delicate surface-mount devices. Consider your project's complexity, component size, and available tool handling skill to select the most efficient solution for your desoldering tasks.

Conclusion: Which Desoldering Method is Right for You?

Desoldering pumps provide quick, efficient solder removal ideal for large joints and rapid work, while solder wick offers precision and control suited for small components and delicate circuit boards. Selecting the right desoldering method depends on the project scale, component sensitivity, and level of detail required, with pumps favoring speed and wicks favoring accuracy. Evaluating these factors ensures optimal solder removal without damaging the PCB or components.

Desoldering pump vs solder wick Infographic

libmatt.com

libmatt.com