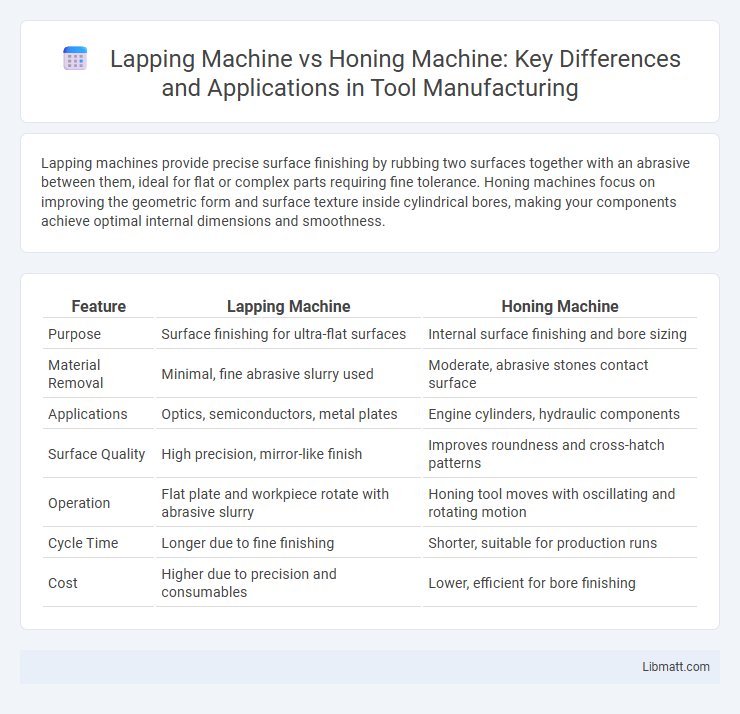

Lapping machines provide precise surface finishing by rubbing two surfaces together with an abrasive between them, ideal for flat or complex parts requiring fine tolerance. Honing machines focus on improving the geometric form and surface texture inside cylindrical bores, making your components achieve optimal internal dimensions and smoothness.

Table of Comparison

| Feature | Lapping Machine | Honing Machine |

|---|---|---|

| Purpose | Surface finishing for ultra-flat surfaces | Internal surface finishing and bore sizing |

| Material Removal | Minimal, fine abrasive slurry used | Moderate, abrasive stones contact surface |

| Applications | Optics, semiconductors, metal plates | Engine cylinders, hydraulic components |

| Surface Quality | High precision, mirror-like finish | Improves roundness and cross-hatch patterns |

| Operation | Flat plate and workpiece rotate with abrasive slurry | Honing tool moves with oscillating and rotating motion |

| Cycle Time | Longer due to fine finishing | Shorter, suitable for production runs |

| Cost | Higher due to precision and consumables | Lower, efficient for bore finishing |

Introduction to Lapping and Honing Machines

Lapping machines use abrasive particles suspended in a liquid to achieve a highly flat, smooth surface finish through a controlled rubbing action between workpieces and lapping plates. Honing machines employ abrasive stones mounted on a rotating tool to improve dimensional accuracy, surface texture, and geometric form inside cylindrical bores. Both machines are essential in precision manufacturing for enhancing surface quality but differ in their applications and operational techniques.

Defining Lapping Machines

Lapping machines are precision machining tools designed to produce ultra-smooth surface finishes by using a fine abrasive slurry between two surfaces in relative motion. They differ from honing machines, which primarily improve geometric accuracy and crosshatch patterns inside cylindrical bores. Your choice depends on the required surface finish, tolerance levels, and specific application needs.

Defining Honing Machines

Honing machines are precision tools designed to improve the geometric form and surface finish of cylindrical parts by removing small amounts of material through abrasive stones. These machines excel at correcting roundness, straightness, and surface texture, making them ideal for fine-tuning components such as engine cylinders and hydraulic parts. Your choice of honing machine ensures enhanced dimensional accuracy and improved performance in critical mechanical assemblies.

Key Differences Between Lapping and Honing

Lapping machines use abrasive slurry between two surfaces to achieve extremely flat, smooth finishes with high precision, often for optical components and semiconductor wafers. Honing machines employ an abrasive stone that rotates and reciprocates inside a bore, improving geometric accuracy and surface texture primarily for engine cylinders and hydraulic components. The key differences lie in application focus: lapping emphasizes flatness and fine surface finishes, while honing enhances internal surface geometry and crosshatch patterns for improved lubrication retention.

How Lapping Machines Work

Lapping machines function by using abrasive particles suspended in a liquid slurry to wear down and smooth the surface of a workpiece through a controlled grinding process. The machine employs a rotating plate or lap, which, combined with specific pressure and motion, ensures uniform material removal and achieves extremely flat, polished finishes. This precise mechanism is essential for applications requiring high surface accuracy and refined tolerances in materials such as metals, ceramics, and optical components.

How Honing Machines Work

Honing machines operate by using abrasive stones mounted on a rotating spindle to achieve precise surface finishes inside cylindrical bores. This process removes minimal material to correct geometry and improve surface texture, enhancing the performance and longevity of engine cylinders and hydraulic components. Your parts gain improved roundness and crosshatch patterns essential for optimal lubrication and sealing.

Applications of Lapping Machines

Lapping machines are primarily used in precision machining to achieve ultra-flat surfaces and tight tolerance finishes on components such as engine parts, optical lenses, and semiconductor wafers. These machines excel in removing microscopic amounts of material to improve dimensional accuracy and surface texture in industries like automotive, aerospace, and electronics. Their ability to produce consistent, high-quality finishes makes them indispensable for applications requiring exceptional flatness and smoothness.

Applications of Honing Machines

Honing machines excel in improving the geometric form and surface finish of metal components, especially in automotive engine cylinders, hydraulic cylinders, and gear parts. Your precision-engineered parts benefit from honing's ability to correct bore size, improve roundness, and enhance surface texture for better sealing and wear resistance. This process is critical in industries demanding high accuracy and surface integrity, such as aerospace, manufacturing, and heavy machinery.

Advantages and Disadvantages: Lapping vs Honing

Lapping machines offer exceptional surface finish and precision flatness, making them ideal for polishing and fine-tuning hard materials, but they are slower and less efficient for removing large amounts of material compared to honing machines. Honing machines excel in improving bore geometry and surface texture by efficiently removing material and reducing cylinder distortion, yet they produce a less mirror-like finish and can cause more tool wear. While lapping provides superior finishing for flat surfaces, honing is more suitable for cylindrical parts requiring high dimensional accuracy and alignment.

Choosing the Right Machine for Your Needs

Selecting between a lapping machine and a honing machine depends on the required surface finish and precision tolerance. Lapping machines excel in achieving ultra-smooth finishes and exact flatness on hard materials, making them ideal for optical lenses and precision gauges. Honing machines offer efficient material removal combined with improved surface texture, suited for cylinder bores and automotive engine components requiring controlled geometry and fine surface quality.

Lapping machine vs honing machine Infographic

libmatt.com

libmatt.com