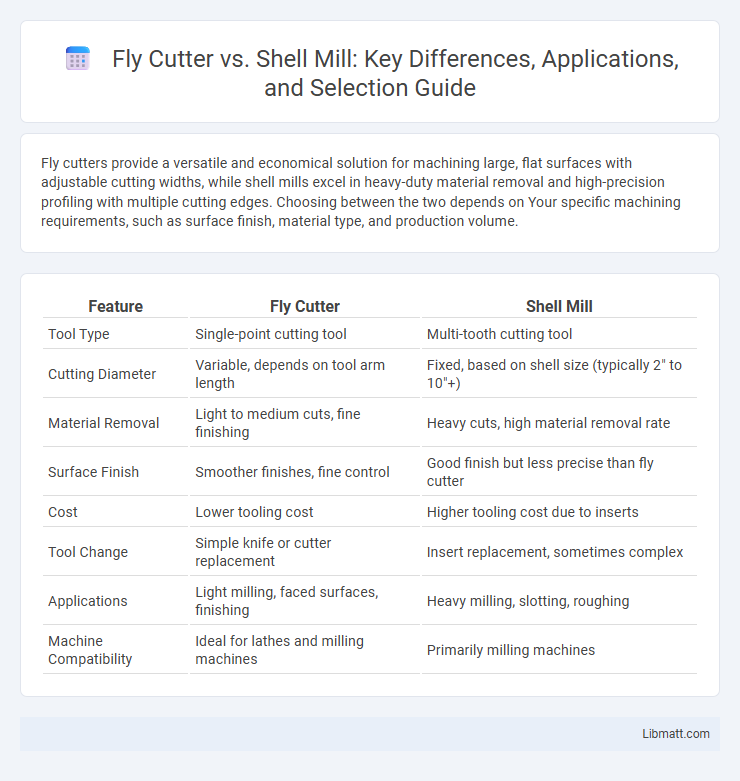

Fly cutters provide a versatile and economical solution for machining large, flat surfaces with adjustable cutting widths, while shell mills excel in heavy-duty material removal and high-precision profiling with multiple cutting edges. Choosing between the two depends on Your specific machining requirements, such as surface finish, material type, and production volume.

Table of Comparison

| Feature | Fly Cutter | Shell Mill |

|---|---|---|

| Tool Type | Single-point cutting tool | Multi-tooth cutting tool |

| Cutting Diameter | Variable, depends on tool arm length | Fixed, based on shell size (typically 2" to 10"+) |

| Material Removal | Light to medium cuts, fine finishing | Heavy cuts, high material removal rate |

| Surface Finish | Smoother finishes, fine control | Good finish but less precise than fly cutter |

| Cost | Lower tooling cost | Higher tooling cost due to inserts |

| Tool Change | Simple knife or cutter replacement | Insert replacement, sometimes complex |

| Applications | Light milling, faced surfaces, finishing | Heavy milling, slotting, roughing |

| Machine Compatibility | Ideal for lathes and milling machines | Primarily milling machines |

Introduction to Fly Cutters and Shell Mills

Fly cutters and shell mills are essential cutting tools used in machining to shape and finish metal surfaces with precision. A fly cutter features a single-point cutting tool mounted on a rotating arm, offering excellent surface finish on large, flat areas, while shell mills have multiple cutting edges, providing higher material removal rates and efficiency for heavy-duty milling tasks. Understanding the distinct capabilities of fly cutters and shell mills helps you select the right tool for achieving optimal machining performance.

Key Differences Between Fly Cutters and Shell Mills

Fly cutters provide a single-point cutting tool ideal for shallow, precise surface finishing on milling machines, while shell mills use multiple cutting edges to achieve higher material removal rates for roughing operations. Fly cutters excel in producing smooth finishes on large, flat surfaces with minimal chatter, whereas shell mills are preferred for heavy-duty cutting and slotting due to their increased stability and efficiency. The key differences lie in their design, cutting capacity, and typical applications, impacting tool selection based on machining requirements.

Design and Construction Comparison

Fly cutters feature a single-point cutting tool mounted on a rotating arm, offering simplicity and ease of maintenance, while shell mills have multiple cutting edges integrated into a cylindrical body for higher material removal rates. The design of fly cutters allows adjustable tool positioning for varied cutting depths, whereas shell mills rely on robust, rigid construction to withstand heavy-duty milling operations. Your choice between the two depends on the required surface finish, cutting efficiency, and the complexity of the workpiece geometry.

Material Removal Rates: Fly Cutter vs Shell Mill

Fly cutters typically offer lower material removal rates compared to shell mills due to their single-point cutting design, making them ideal for finishing operations and achieving fine surface finishes. Shell mills utilize multiple cutting edges, which distribute the cutting load and allow higher feed rates and deeper cuts, resulting in significantly increased material removal rates. For high-volume machining of tougher materials, shell mills provide superior efficiency and productivity compared to the slower, more precise fly cutters.

Surface Finish and Quality Considerations

Fly cutters typically produce a smoother surface finish due to their single-point cutting action, which reduces tool marks and irregularities. Shell mills, with multiple cutting edges, can remove material faster but might leave a rougher surface without precise tool alignment and proper feed rates. For superior surface quality, fly cutters are preferred in fine finishing operations, while shell mills excel in roughing and high material removal scenarios.

Best Applications for Fly Cutters

Fly cutters are best suited for creating smooth, flat surfaces on large workpieces, achieving fine finishes in metalworking and woodworking tasks. They excel in producing precise face milling on lathes or milling machines with relatively low spindle speeds. Ideal applications include surfacing castings, flanges, and large plates where uniform material removal and fine surface quality are critical.

Best Applications for Shell Mills

Shell mills excel in high-performance milling operations requiring large material removal rates, such as face milling, slotting, and shoulder milling on steel, cast iron, and aluminum workpieces. Their modular design, with replaceable inserts, allows efficient handling of heavy-duty tasks and extended tool life, making them ideal for production environments and large surface finishes. Compared to fly cutters, shell mills offer higher rigidity, better balance, and faster feed rates, suitable for machining large, flat, or stepped surfaces with precision.

Tool Life and Maintenance Factors

Fly cutters generally offer longer tool life due to their simple design with fewer moving parts, reducing wear and maintenance frequency. Shell mills, while providing higher material removal rates, require more frequent maintenance because of their multiple indexable inserts that wear unevenly. Optimizing your machining process involves balancing the ease of maintenance of fly cutters with the high productivity and insert replacement costs associated with shell mills.

Cost Efficiency and Budget Considerations

Fly cutters offer a lower initial investment cost compared to shell mills, making them ideal for small workshops with tight budgets. Shell mills provide faster material removal rates and longer tool life, which can reduce overall production costs in high-volume manufacturing. Choosing between the two depends on balancing upfront tooling expenses with long-term operational savings.

Choosing the Right Tool for Your Milling Needs

Fly cutters and shell mills offer unique advantages for milling tasks based on material removal rates and surface finish requirements. Fly cutters excel in producing smooth finishes on large, flat surfaces with a single-point cutting action, ideal for light to moderate cuts and precision work. Shell mills provide higher material removal rates and versatility for roughing and finishing tougher materials, making them suitable for heavy-duty operations and deeper cuts.

Fly cutter vs shell mill Infographic

libmatt.com

libmatt.com