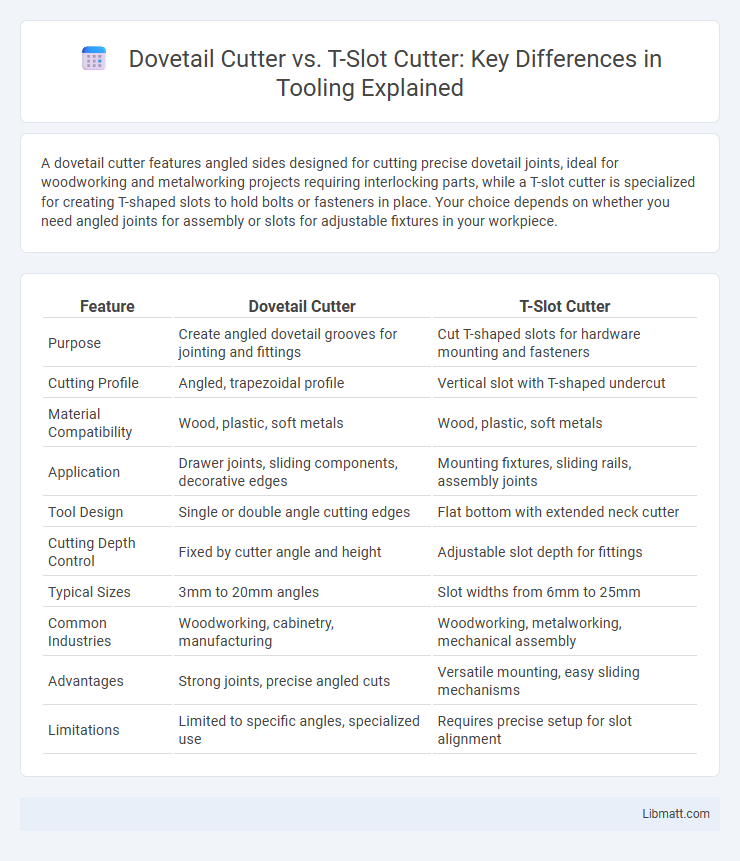

A dovetail cutter features angled sides designed for cutting precise dovetail joints, ideal for woodworking and metalworking projects requiring interlocking parts, while a T-slot cutter is specialized for creating T-shaped slots to hold bolts or fasteners in place. Your choice depends on whether you need angled joints for assembly or slots for adjustable fixtures in your workpiece.

Table of Comparison

| Feature | Dovetail Cutter | T-Slot Cutter |

|---|---|---|

| Purpose | Create angled dovetail grooves for jointing and fittings | Cut T-shaped slots for hardware mounting and fasteners |

| Cutting Profile | Angled, trapezoidal profile | Vertical slot with T-shaped undercut |

| Material Compatibility | Wood, plastic, soft metals | Wood, plastic, soft metals |

| Application | Drawer joints, sliding components, decorative edges | Mounting fixtures, sliding rails, assembly joints |

| Tool Design | Single or double angle cutting edges | Flat bottom with extended neck cutter |

| Cutting Depth Control | Fixed by cutter angle and height | Adjustable slot depth for fittings |

| Typical Sizes | 3mm to 20mm angles | Slot widths from 6mm to 25mm |

| Common Industries | Woodworking, cabinetry, manufacturing | Woodworking, metalworking, mechanical assembly |

| Advantages | Strong joints, precise angled cuts | Versatile mounting, easy sliding mechanisms |

| Limitations | Limited to specific angles, specialized use | Requires precise setup for slot alignment |

Understanding Dovetail Cutters: Key Features

Dovetail cutters feature angled cutting edges designed for creating precision dovetail joints commonly used in woodworking and metalworking. Their tapered profile allows for secure interlocking parts, enhancing joint strength and stability. These cutters typically have a specific included angle, such as 60deg or 90deg, which is crucial for matching the dovetail slot's dimensions accurately.

What is a T-slot Cutter? Overview and Functions

A T-slot cutter is a specialized milling tool designed to cut T-shaped slots in materials, commonly used for creating slots that hold machine components or fixtures securely. Its unique profile allows it to machine undercut slots, which standard end mills cannot achieve, making it ideal for applications such as securing bolts or fasteners in machine tables or workpieces. Understanding the function of a T-slot cutter can enhance your machining precision when fabricating parts that require interlocking features or adjustable components.

Material Compatibility: Dovetail vs T-slot Cutters

Dovetail cutters excel at machining hard materials like steel and cast iron due to their robust angled profiles that provide precision in creating dovetail joints. T-slot cutters are optimized for softer materials such as aluminum and plastic, designed to produce the wider grooves found in T-slots with smooth finishes. Choosing the right cutter depends on your material's hardness, ensuring optimal performance and tool life.

Design Differences Between Dovetail and T-slot Cutters

Dovetail cutters feature angled cutting edges designed to create precise, tapered grooves ideal for dovetail joints, while T-slot cutters have a straight cutting profile with a wider bottom to form T-shaped slots for securing components. The distinctive geometry of dovetail cutters allows for tight interlocking parts, contrasting with T-slot cutters' design optimized for adjustable fixtures and sliding nuts. Understanding these design differences helps you select the right cutter for machining applications requiring specific joint types or slot configurations.

Typical Applications: When to Use Each Cutter

Dovetail cutters are ideal for creating angled slots and joints in woodworking and metalworking, commonly used in dovetail joints for drawer construction and mechanical clamp fittings. T-slot cutters excel in machining precise T-shaped slots for securing fixtures, workpieces, or machine components on milling tables and machine beds. Your choice depends on the joint or slot type required, with dovetail cutters suited for angled interlocking connections and T-slot cutters designed for standardized, straight slots to hold fasteners or mounts.

Precision and Finish: Comparing Cutting Results

Dovetail cutters deliver exceptional precision with their angled flutes designed for tight interlocking joints, producing smooth finishes ideal for woodworking and metalworking projects requiring exact fits. T-slot cutters are optimized for cutting slots with uniform width and flat bottoms, offering clean edges and consistent depths crucial for mechanical assemblies and adjustable fixtures. Both cutters provide high-quality finishes but differ in application-specific precision, with dovetail cutters excelling in angled groove accuracy and T-slot cutters ensuring dimensional uniformity.

Cutting Speed and Efficiency Analysis

Dovetail cutters typically operate at moderate cutting speeds optimized for precision in angled groove profiling, while T-slot cutters accommodate higher cutting speeds due to their simpler straight-edge design, enhancing material removal rates. The efficiency of dovetail cutters is tailored towards detailed, angled cuts requiring slower feed rates to maintain accuracy, whereas T-slot cutters achieve faster throughput in slotting operations through more aggressive cutting parameters. Selecting the appropriate cutter involves balancing the need for cutting speed against the geometric complexity of the task, with T-slot cutters offering superior efficiency in high-volume production due to their robust cutting angles and feed capabilities.

Tool Selection Guide: Choosing the Right Cutter

Choosing the right cutter depends on the machining application--Dovetail cutters are ideal for creating angled slots and joints requiring precise undercuts, while T-slot cutters excel in producing straight-sided slots with a perpendicular profile for mounting. Material type, slot dimensions, and machine compatibility are critical factors; Dovetail cutters often require rigid setups for accuracy, whereas T-slot cutters provide versatility in slot widths and depths. Prioritize cutter geometry, flute design, and coating to match workpiece material and desired finish, ensuring optimal tool life and machining efficiency.

Maintenance and Longevity: Which Tool Lasts Longer?

Dovetail cutters, designed for precision and angled cuts, typically require frequent maintenance due to their complex geometry, which can lead to faster wear compared to T-slot cutters. T-slot cutters, with their simpler profile and robust design, generally offer greater longevity when used in machining slots and T-shaped grooves, as they endure less stress during operation. Proper lubrication and regular sharpening extend the lifespan of both tools, but T-slot cutters often maintain cutting efficiency longer under similar operating conditions.

Cost Factors: Dovetail Cutter vs T-slot Cutter

Dovetail cutters typically have higher manufacturing costs due to their complex angled profiles and precise tip geometries compared to standard T-slot cutters, which feature simpler, straight cutting edges. The material composition and durability requirements also influence cost differences, with dovetail cutters often requiring more wear-resistant coatings to maintain tolerances. When selecting between the two, your budget should consider not only the initial tool price but also tool life and maintenance frequency, as dovetail cutters may offer longer service despite their higher upfront cost.

Dovetail cutter vs T-slot cutter Infographic

libmatt.com

libmatt.com