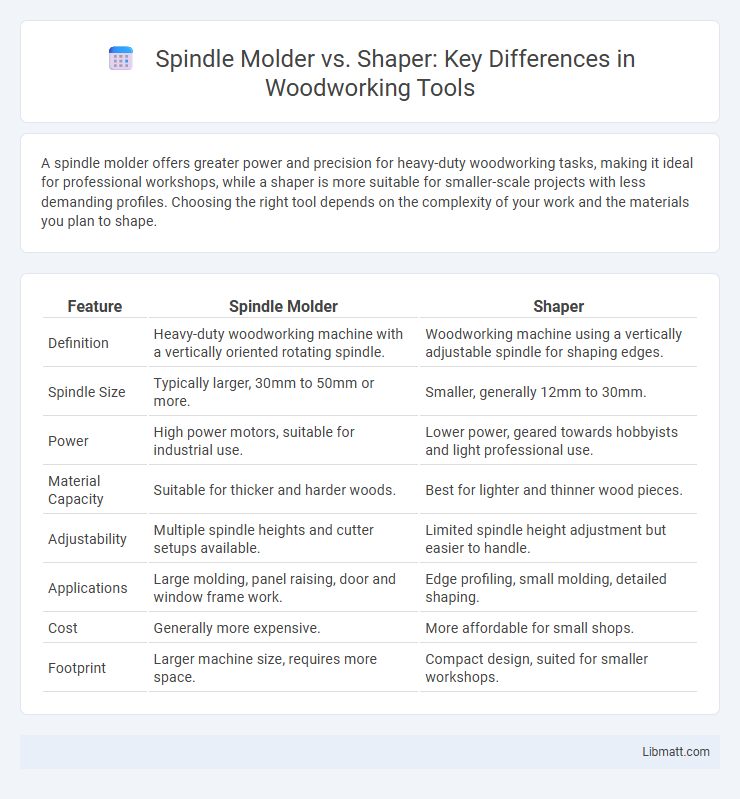

A spindle molder offers greater power and precision for heavy-duty woodworking tasks, making it ideal for professional workshops, while a shaper is more suitable for smaller-scale projects with less demanding profiles. Choosing the right tool depends on the complexity of your work and the materials you plan to shape.

Table of Comparison

| Feature | Spindle Molder | Shaper |

|---|---|---|

| Definition | Heavy-duty woodworking machine with a vertically oriented rotating spindle. | Woodworking machine using a vertically adjustable spindle for shaping edges. |

| Spindle Size | Typically larger, 30mm to 50mm or more. | Smaller, generally 12mm to 30mm. |

| Power | High power motors, suitable for industrial use. | Lower power, geared towards hobbyists and light professional use. |

| Material Capacity | Suitable for thicker and harder woods. | Best for lighter and thinner wood pieces. |

| Adjustability | Multiple spindle heights and cutter setups available. | Limited spindle height adjustment but easier to handle. |

| Applications | Large molding, panel raising, door and window frame work. | Edge profiling, small molding, detailed shaping. |

| Cost | Generally more expensive. | More affordable for small shops. |

| Footprint | Larger machine size, requires more space. | Compact design, suited for smaller workshops. |

Introduction to Spindle Molders and Shapers

Spindle molders and shapers are woodworking machines designed to shape and profile wood edges with precision using various interchangeable cutters. Spindle molders feature a vertically oriented spindle that rotates at high speeds, allowing for detailed molding and shaping on wood surfaces. Shapers, often used interchangeably with spindle molders, are essential for creating complex profiles on wood pieces, enabling versatile cuts for cabinetry, furniture, and decorative trim.

Key Differences Between Spindle Molders and Shapers

Spindle molders and shapers both serve woodworking shaping purposes but differ primarily in their design and application. Spindle molders feature an exposed, adjustable spindle suitable for heavier, more precise cutting operations, while shapers use vertical cutters with less height adjustment but faster setup for repetitive tasks. Your choice depends on the complexity of shaping needed, with spindle molders offering greater versatility and shapers excelling in efficiency for production runs.

Construction and Build Quality

Spindle molders feature a robust cast iron table and heavy-duty motor mounting, ensuring superior stability and reduced vibrations during intensive woodworking tasks. Shapers often incorporate precision-engineered components with adjustable fence systems and interchangeable spindles, allowing for versatile cutters and enhanced build quality. Both tools emphasize solid construction, but spindle molders typically offer greater rigidity suited for professional workshops requiring high accuracy.

Ease of Use and Operation

Spindle molders offer greater ease of use due to their adjustable fences and precise depth controls, allowing for more accurate and repeatable operations. Shapers are generally simpler to operate with straightforward spindle speed adjustments and quick tooling changes, making them ideal for less complex woodworking tasks. Both tools provide user-friendly features, but spindle molders excel in versatility and meticulous control during detailed shaping projects.

Cutters and Tooling Options

Spindle molders and shapers both use interchangeable cutters, but spindle molders typically have a more versatile and comprehensive range of tooling options due to their higher spindle speeds and heavier construction. Your choice of cutter material--carbide, HSS, or diamond-tipped--plays a crucial role in tooling performance, with spindle molders better suited for larger, more complex profiles and shapers ideal for fine, precision cuts. Tooling options also include various cutter diameters and profiles, allowing spindle molders to handle wider stock sizes and more aggressive cuts compared to shapers.

Versatility and Applications

Spindle molders offer greater versatility with interchangeable heads and adjustable cutting accessories, enabling precise woodworking tasks like molding, grooving, and tenoning on various materials. Shapers excel in heavy-duty shaping and profiling, especially for cabinet making and door construction, with more powerful motors for thicker stock. Your choice depends on whether you prioritize flexible customization (spindle molder) or robust capacity for complex shapes (shaper).

Safety Features and Considerations

Spindle molders and shapers both feature essential safety mechanisms such as adjustable guards, emergency stop buttons, and anti-kickback devices to prevent accidents during woodworking tasks. Your choice should consider spindle molder models offering enhanced dust extraction ports and automatic blade braking systems for increased safety. Proper use of push sticks and securing workpieces is critical to minimize risk, regardless of the machine type.

Power, Speed, and Performance

Spindle molders typically offer higher power ratings, ranging from 2 to 5 horsepower, compared to shapers, which usually have motors between 1.5 and 3 horsepower, enabling more heavy-duty cutting tasks. Spindle molders operate at variable speeds, often between 3,000 to 10,000 RPM, providing greater flexibility for a variety of woodworking applications, while shapers generally run at lower, fixed speeds around 1,725 to 3,450 RPM. In terms of performance, spindle molders deliver superior precision and versatility for complex profiles and industrial production, whereas shapers are better suited for lighter woodworking projects and smaller-scale operations.

Maintenance Requirements and Durability

Spindle molders typically demand regular lubrication and precise alignment checks to maintain optimal performance, as their spindle bearings bear significant stress. Shapers require routine blade sharpening and careful inspection of the ram mechanism to prevent wear and ensure durability. Both tools benefit from dust extraction systems to prolong motor life and maintain cutting accuracy.

Choosing the Right Machine for Your Workshop

Selecting between a spindle molder and a shaper depends on your workshop's specific woodworking needs and project scope. Spindle molders offer greater versatility with variable speed control and interchangeable spindles, making them ideal for intricate molding and large-scale production. Shapers provide robust power for heavy-duty shaping tasks, favored in custom cabinetry and furniture making where precision and stability are crucial.

Spindle molder vs shaper Infographic

libmatt.com

libmatt.com