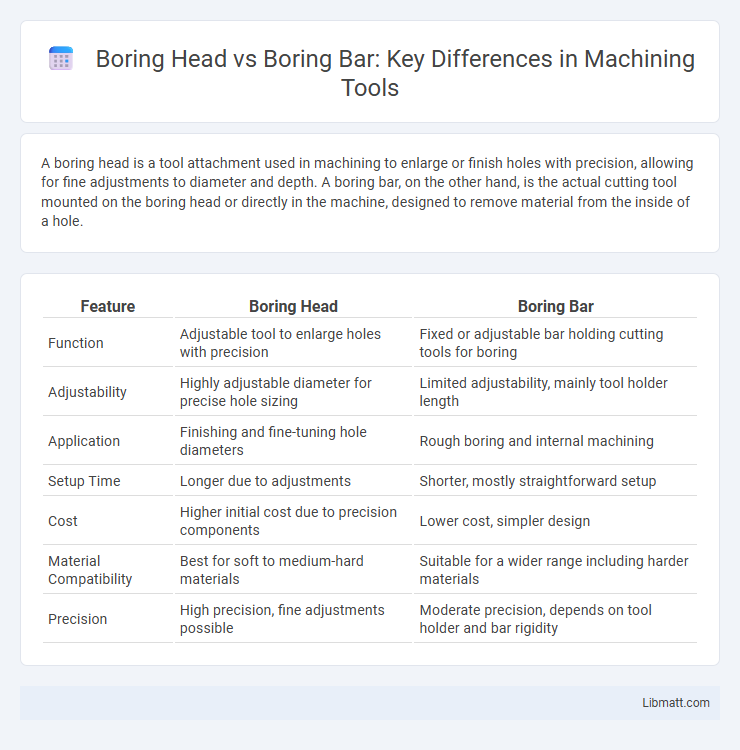

A boring head is a tool attachment used in machining to enlarge or finish holes with precision, allowing for fine adjustments to diameter and depth. A boring bar, on the other hand, is the actual cutting tool mounted on the boring head or directly in the machine, designed to remove material from the inside of a hole.

Table of Comparison

| Feature | Boring Head | Boring Bar |

|---|---|---|

| Function | Adjustable tool to enlarge holes with precision | Fixed or adjustable bar holding cutting tools for boring |

| Adjustability | Highly adjustable diameter for precise hole sizing | Limited adjustability, mainly tool holder length |

| Application | Finishing and fine-tuning hole diameters | Rough boring and internal machining |

| Setup Time | Longer due to adjustments | Shorter, mostly straightforward setup |

| Cost | Higher initial cost due to precision components | Lower cost, simpler design |

| Material Compatibility | Best for soft to medium-hard materials | Suitable for a wider range including harder materials |

| Precision | High precision, fine adjustments possible | Moderate precision, depends on tool holder and bar rigidity |

Introduction: Boring Head vs Boring Bar

A boring head is a precision tool attachment used on milling machines or boring mills for enlarging holes with high accuracy and fine surface finishes. A boring bar, contrastingly, is the cutting tool itself, often mounted on a boring head or directly in a tool holder, designed to machine the internal diameter of a hole. Understanding the difference between your boring head and boring bar is essential for selecting the right setup to achieve optimal hole sizing and finish quality in machining operations.

What is a Boring Head?

A boring head is a precision tool attachment used in machining to enlarge existing holes with high accuracy and smooth finish. It mounts on a boring bar or machine spindle and allows adjustable cutting diameter through an adjustable arm or dial, enabling precise hole size control. Commonly used in milling machines and boring mills, boring heads ensure reaming or finishing holes to exact specifications.

What is a Boring Bar?

A boring bar is a precision cutting tool used in machining to enlarge or finish the inside diameter of a hole with high accuracy. It typically consists of a solid shank with a cutting insert mounted on one end, designed to remove material for smooth and precise internal surfaces. Your choice of a boring bar impacts the quality and tolerance of the machined bore, making it essential for applications requiring tight dimensional control.

Key Differences Between Boring Head and Boring Bar

Boring heads allow precise diameter adjustment and can be mounted on milling machines or lathes, offering high versatility for internal machining. Boring bars are rigid, long tools designed primarily for deep hole boring on lathes, focusing on stability and minimal vibration. The key differences lie in adjustability and application: boring heads provide fine tuning for diameter control, while boring bars excel in reaching deep or hard-to-access areas with consistent cutting performance.

Applications of Boring Heads

Boring heads are primarily used for precision enlarging and finishing of existing holes in metalworking, offering high accuracy and surface finish quality for applications such as engine cylinder bores, valve seats, and bearing housings. Their adjustable cutting diameter allows for versatile machining in heavy-duty and fine-tuning tasks, making them ideal in industries such as aerospace, automotive, and manufacturing. Compared to boring bars, boring heads provide superior stability and control when performing internal boring operations requiring tight tolerances.

Applications of Boring Bars

Boring bars are primarily used for precision internal machining tasks such as enlarging holes or creating tapered bores in metalworking and manufacturing industries. Unlike boring heads, which are adjustable toolholders for precision diameter control, boring bars provide stability and rigidity for deeper or heavy-duty boring applications. Your choice of boring bar can significantly affect machining accuracy and surface finish, especially in automotive and aerospace component production.

Advantages of Using a Boring Head

Using a boring head provides superior precision and flexibility in enlarging holes to exact diameters, ensuring high-quality finishes in machining operations. It allows for fine adjustments and can accommodate different boring bar sizes, enabling versatile use on various machines. The adaptability and accuracy of a boring head reduce setup time and improve overall efficiency in metalworking processes.

Advantages of Using a Boring Bar

A boring bar offers precise control and stability, allowing you to achieve tighter tolerances and smoother surface finishes in your machining projects. Unlike a boring head, a boring bar provides greater versatility for internal and external turning operations, making it ideal for complex and customized cuts. Your machining efficiency and accuracy significantly improve by using a boring bar due to its rigid design and ease of tool adjustment.

Choosing the Right Tool: Boring Head or Boring Bar

Choosing the right tool between a boring head and a boring bar depends on the machining precision and setup flexibility required. Boring heads offer adjustable diameter control, ideal for achieving tight tolerances and fine surface finishes in cylindrical holes. Boring bars provide stability and rigidity for deep hole boring but may have less diameter adjustment capability compared to boring heads.

Conclusion: Which is Better for Your Machining Needs?

A boring head offers greater versatility and precision for internal diameter adjustments, making it ideal for detailed and fine-tuned machining tasks. A boring bar excels in stability and rigidity, suited for heavy-duty material removal and deep hole boring. Your choice depends on whether precision or robustness is the priority for your specific machining requirements.

Boring head vs boring bar Infographic

libmatt.com

libmatt.com