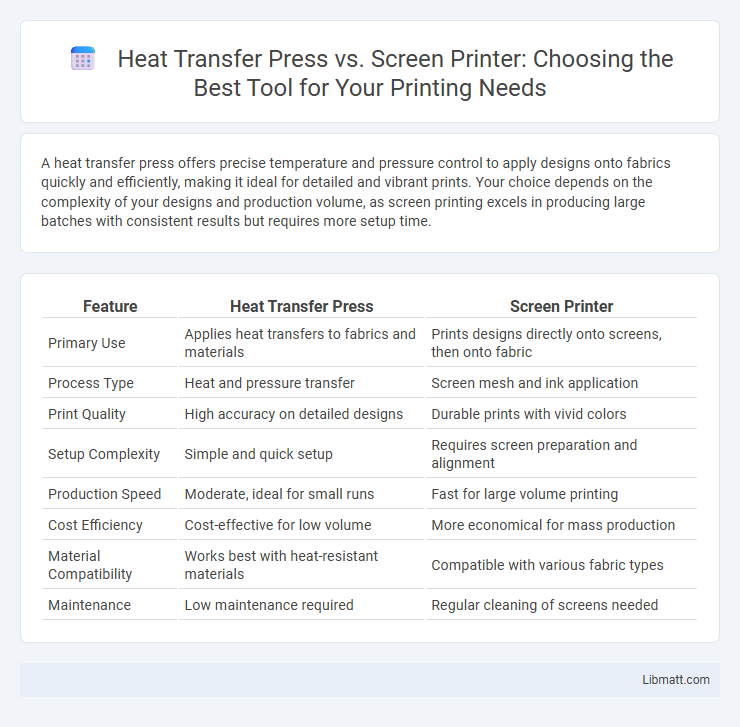

A heat transfer press offers precise temperature and pressure control to apply designs onto fabrics quickly and efficiently, making it ideal for detailed and vibrant prints. Your choice depends on the complexity of your designs and production volume, as screen printing excels in producing large batches with consistent results but requires more setup time.

Table of Comparison

| Feature | Heat Transfer Press | Screen Printer |

|---|---|---|

| Primary Use | Applies heat transfers to fabrics and materials | Prints designs directly onto screens, then onto fabric |

| Process Type | Heat and pressure transfer | Screen mesh and ink application |

| Print Quality | High accuracy on detailed designs | Durable prints with vivid colors |

| Setup Complexity | Simple and quick setup | Requires screen preparation and alignment |

| Production Speed | Moderate, ideal for small runs | Fast for large volume printing |

| Cost Efficiency | Cost-effective for low volume | More economical for mass production |

| Material Compatibility | Works best with heat-resistant materials | Compatible with various fabric types |

| Maintenance | Low maintenance required | Regular cleaning of screens needed |

Introduction: Heat Transfer Press vs Screen Printer

Heat transfer presses use heat and pressure to transfer designs from vinyl or printed materials onto fabrics, ensuring vibrant and durable prints ideal for small runs and detailed images. Screen printers apply ink through stencils on mesh screens directly onto garments, offering cost-effective, high-volume production with excellent color opacity and durability. Choosing between a heat transfer press and screen printer depends on factors like order size, design complexity, fabric type, and desired print longevity.

Overview of Heat Transfer Press Technology

Heat transfer press technology uses high temperature and pressure to transfer designs from a vinyl or sublimation paper onto fabrics, ensuring vibrant, durable prints with precise detailing. Unlike screen printing, which relies on stencils and ink layers, heat transfer presses enable quick customization and work efficiently on various materials, including polyester and cotton blends. Your choice of a heat transfer press provides flexibility for small batch production and intricate multicolor designs without the setup complexity of traditional screen printing.

Overview of Screen Printing Technology

Screen printing technology uses a mesh stencil to transfer ink onto a substrate, creating vibrant and durable designs ideal for textiles and promotional items. It allows for precise color layering and high-volume production, making it a cost-effective choice for bulk orders. You can achieve detailed, long-lasting prints with versatile ink options suited for various materials.

Cost Comparison: Equipment and Materials

Heat transfer presses typically have lower initial equipment costs, ranging from $200 to $2,000, while screen printers require expensive setups often exceeding $1,500 for basic models. Material expenses for heat transfer printing include heat transfer vinyl or transfer paper, which can be more affordable and produce less waste compared to the costly screens, inks, and emulsions needed for screen printing. Overall, heat transfer presses present a more budget-friendly option for small-scale or customized projects, whereas screen printing is cost-effective for large print runs due to economies of scale.

Print Quality and Durability

Heat transfer presses offer superior print quality with vibrant, detailed designs due to precise heat application and controlled pressure settings. Screen printers produce durable prints with excellent color vibrancy, especially on larger quantities, as the ink bonds deeply into fabric fibers. While heat transfer prints may fade faster under heavy washing, screen printed designs generally maintain durability and color integrity over extended wear.

Production Speed and Efficiency

Heat transfer presses offer faster production speeds due to their quick heating and pressing cycles, making them ideal for short runs and custom designs. Screen printers excel in efficiency for large-volume orders, as they can produce consistent prints rapidly once the setup is complete. Your choice depends on whether you prioritize rapid turnaround for smaller batches or high-efficiency output for mass production.

Design Versatility and Color Capabilities

Heat transfer presses offer extensive design versatility, allowing you to transfer complex, full-color images with gradients and photographic detail onto various fabrics. Screen printers excel in producing vibrant, solid colors with excellent color opacity and durability, especially for bulk orders with limited color palettes. Your choice depends on whether you prioritize intricate color blending or bold, long-lasting prints.

Suitability for Different Fabrics and Materials

Heat transfer presses excel at applying designs on synthetic fabrics like polyester and blends due to their ability to bond heat-activated inks effectively. Screen printers offer superior durability and color vibrancy on natural fibers such as cotton and linen, making them ideal for high-volume runs with various ink types. Your choice depends on the fabric composition and desired print quality, ensuring the method aligns with the material's heat sensitivity and texture.

Best Applications for Each Printing Method

Heat transfer presses are ideal for producing vibrant, full-color designs on a variety of fabrics, making them perfect for small runs, custom apparel, and detailed images with gradients or photo-quality prints. Screen printers excel in high-volume orders with simple, bold designs and limited color palettes, delivering durable, cost-effective prints on cotton and polyester textiles. Your choice between these methods depends on whether you prioritize intricate detail and color diversity (heat press) or efficiency and durability for mass production (screen printing).

Choosing the Right Printing Technique for Your Business

Heat transfer presses offer precise, vibrant designs ideal for small to medium runs, while screen printers excel in producing large volumes with lower per-unit costs. Your choice depends on factors like order size, color complexity, and budget constraints, with heat transfer providing flexibility and screen printing delivering durability. Evaluating these aspects ensures you select the most efficient and cost-effective printing technique for your business needs.

Heat transfer press vs screen printer Infographic

libmatt.com

libmatt.com