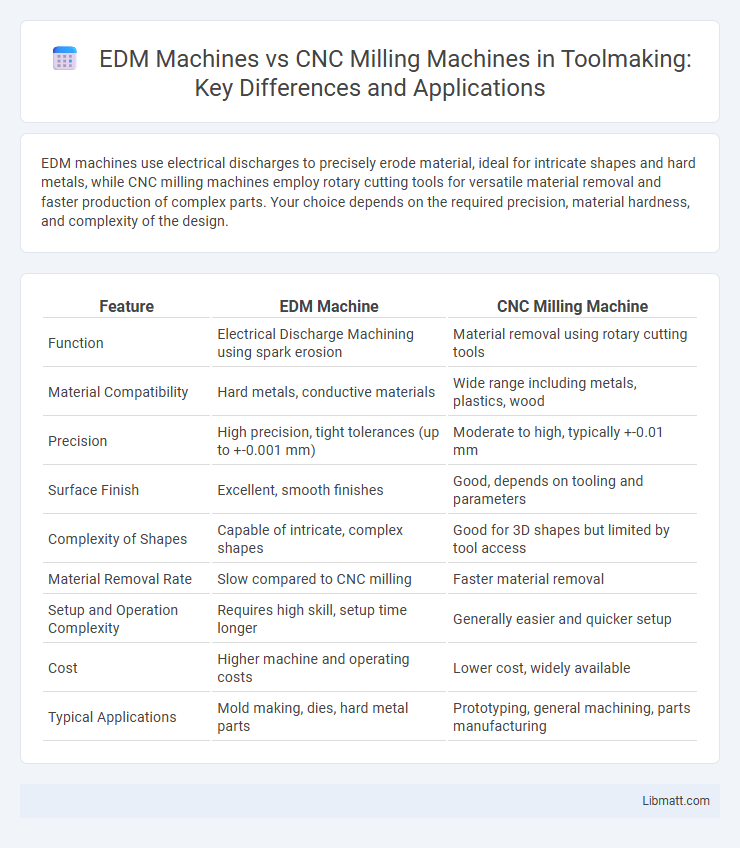

EDM machines use electrical discharges to precisely erode material, ideal for intricate shapes and hard metals, while CNC milling machines employ rotary cutting tools for versatile material removal and faster production of complex parts. Your choice depends on the required precision, material hardness, and complexity of the design.

Table of Comparison

| Feature | EDM Machine | CNC Milling Machine |

|---|---|---|

| Function | Electrical Discharge Machining using spark erosion | Material removal using rotary cutting tools |

| Material Compatibility | Hard metals, conductive materials | Wide range including metals, plastics, wood |

| Precision | High precision, tight tolerances (up to +-0.001 mm) | Moderate to high, typically +-0.01 mm |

| Surface Finish | Excellent, smooth finishes | Good, depends on tooling and parameters |

| Complexity of Shapes | Capable of intricate, complex shapes | Good for 3D shapes but limited by tool access |

| Material Removal Rate | Slow compared to CNC milling | Faster material removal |

| Setup and Operation Complexity | Requires high skill, setup time longer | Generally easier and quicker setup |

| Cost | Higher machine and operating costs | Lower cost, widely available |

| Typical Applications | Mold making, dies, hard metal parts | Prototyping, general machining, parts manufacturing |

Introduction to EDM and CNC Milling Machines

EDM (Electrical Discharge Machining) uses controlled electrical sparks to erode metal, ideal for creating intricate shapes and hard-to-machine materials. CNC milling machines rely on rotary cutting tools controlled by computer programs to remove material, suited for a wide variety of applications including complex 3D parts. Your choice depends on factors like material hardness, precision requirements, and the complexity of the design.

Fundamental Working Principles

EDM machines operate by eroding material through controlled electrical discharges between an electrode and the workpiece, ideal for complex shapes and hard materials. CNC milling machines remove material using rotary cutting tools guided by programmed paths, excelling in precision and surface finish on softer metals. Your choice depends on whether electrical discharge or mechanical cutting better suits your machining requirements.

Key Differences Between EDM and CNC Milling

EDM (Electrical Discharge Machining) uses electrical discharges to precisely erode conductive materials, making it ideal for intricate shapes and hard metals that are difficult to machine with CNC milling. CNC milling employs rotary cutters to remove material from a workpiece, excelling in machining softer metals and plastics with high-speed material removal and smoother surface finishes. Key differences include EDM's ability to machine complex geometries without physical contact and CNC milling's efficiency in producing parts with tight dimensional tolerances and higher material removal rates.

Materials Suitable for Each Technology

EDM machines excel in machining hard, conductive materials such as hardened steel, titanium, and carbide that are difficult to process with traditional cutting tools. CNC milling machines are versatile for a broader range of materials including aluminum, plastics, wood, and softer metals, offering high-speed material removal and precision shaping. The choice between EDM and CNC milling depends on material hardness, conductivity, and the desired surface finish or geometric complexity.

Precision and Surface Finish Comparison

EDM machines offer superior precision by using electrical discharges to erode material, achieving tolerances as tight as +-0.002 mm and producing extremely smooth surface finishes ideal for intricate details and hard materials. CNC milling machines provide good precision with tolerances typically around +-0.01 mm but may require additional finishing processes to achieve a comparable surface quality. Your choice depends on the complexity and surface finish demands of your project, with EDM excelling in fine detail and superior surface smoothness.

Speed and Efficiency: EDM vs CNC Milling

EDM machines excel in precision cutting of hard metals with intricate details, often achieving faster results on complex geometries that CNC milling machines struggle with. CNC milling offers higher speed and efficiency for removing large volumes of material and producing parts with simpler shapes, making it ideal for rapid prototyping and mass production. Your choice depends on whether speed in detailed, hard material work or efficient bulk material removal suits your project requirements.

Tool Wear and Maintenance Requirements

EDM machines experience minimal tool wear since they use electrical discharges to erode material without direct contact, unlike CNC milling machines where cutting tools physically wear down due to friction and heat. Maintenance for EDM machines primarily involves checking the dielectric fluid and electrode conditions, while CNC milling demands frequent tool replacement and spindle upkeep. Your choice between these depends on balancing precision needs against ongoing maintenance costs and tool longevity.

Typical Applications in Modern Manufacturing

EDM machines excel in producing intricate shapes and fine details in hard materials like hardened steel or titanium, making them essential for mold making, aerospace components, and medical device manufacturing. CNC milling machines offer versatility for a wide range of materials, enabling rapid prototyping, complex 3D surface machining, and high-precision parts for automotive, electronics, and consumer goods industries. Both technologies complement each other by addressing different manufacturing demands, combining precision and efficiency in modern production workflows.

Cost Considerations and ROI Analysis

EDM machines generally have higher initial costs due to specialized components and maintenance requirements, but offer greater precision and material versatility, which can enhance long-term value in specialized manufacturing. CNC milling machines typically feature lower upfront expenses and faster cycle times, enabling quicker ROI in high-volume production settings with standard materials. Evaluating ROI depends on production scale, material complexity, and required tolerances, where EDM yields better returns in intricate, low-volume jobs, and CNC milling excels in efficiency-driven environments.

Choosing the Right Machine for Your Project

EDM machines excel in creating complex shapes and fine details in hard metals with high precision, making them ideal for intricate molds and dies. CNC milling machines offer versatility and faster material removal for a wide range of materials and applications, providing efficiency in prototyping and production runs. Assess your project's complexity, material type, and precision requirements to determine whether EDM or CNC milling best suits your manufacturing needs.

EDM machine vs CNC milling machine Infographic

libmatt.com

libmatt.com