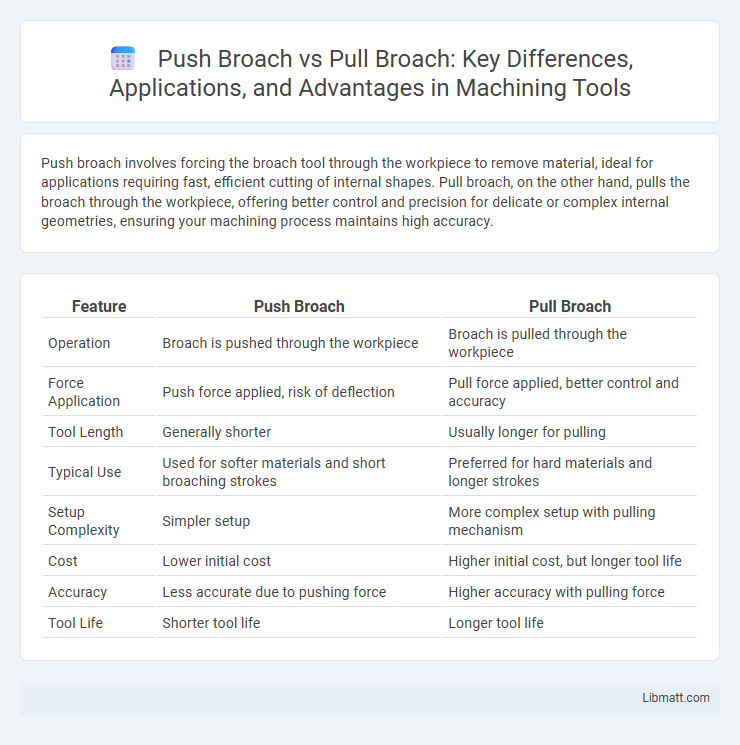

Push broach involves forcing the broach tool through the workpiece to remove material, ideal for applications requiring fast, efficient cutting of internal shapes. Pull broach, on the other hand, pulls the broach through the workpiece, offering better control and precision for delicate or complex internal geometries, ensuring your machining process maintains high accuracy.

Table of Comparison

| Feature | Push Broach | Pull Broach |

|---|---|---|

| Operation | Broach is pushed through the workpiece | Broach is pulled through the workpiece |

| Force Application | Push force applied, risk of deflection | Pull force applied, better control and accuracy |

| Tool Length | Generally shorter | Usually longer for pulling |

| Typical Use | Used for softer materials and short broaching strokes | Preferred for hard materials and longer strokes |

| Setup Complexity | Simpler setup | More complex setup with pulling mechanism |

| Cost | Lower initial cost | Higher initial cost, but longer tool life |

| Accuracy | Less accurate due to pushing force | Higher accuracy with pulling force |

| Tool Life | Shorter tool life | Longer tool life |

Introduction to Broaching Processes

Push broaching and pull broaching are two primary methods in broaching processes used to machine precision holes or complex internal shapes. Push broaching involves the tool being pushed through the workpiece, commonly applied for shorter broaches and limited depth, while pull broaching pulls the tool through the material, allowing for longer broaches and greater control over surface finish. Both processes rely on progressive cutting teeth to shape or size holes, with the choice between push and pull broaching depending on workpiece geometry and production requirements.

What is Push Broaching?

Push broaching is a machining process where the broach tool is pushed through the workpiece to remove material and shape internal surfaces. This method is often used for creating keyways, splines, or other precise internal profiles in metals and alloys. You benefit from push broaching when high accuracy and surface finish are required in confined spaces.

What is Pull Broaching?

Pull broaching is a machining process where a toothed tool, called a broach, is pulled through a workpiece to remove material and create precise internal or external shapes. It offers superior control and accuracy compared to push broaching, minimizing tool deflection and producing smoother finishes. Commonly used in producing keyways, splines, and internal gears, pull broaching enhances machining efficiency in high-precision manufacturing applications.

Key Differences Between Push and Pull Broaches

Push broaches operate by driving the tool forward through the workpiece, applying force from the front to shape or enlarge a hole, while pull broaches are pulled through the material, providing better control and accuracy. Push broaching is generally faster but may cause more tool wear and less precise results, whereas pull broaching offers smoother finishes and allows for longer tool life due to reduced stress. Your choice between push and pull broaching depends on factors like material hardness, desired finish quality, and production speed requirements.

Advantages of Push Broaching

Push broaching offers advantages such as improved control over the cutting process, reducing tool deflection and enhancing accuracy for complex shapes. This method typically requires less force compared to pull broaching, minimizing stress on machine components and extending tool life. Your manufacturing process benefits from push broach's ability to produce consistent, high-precision parts with reduced risk of tool breakage.

Advantages of Pull Broaching

Pull broaching offers greater precision and surface finish quality compared to push broaching due to the controlled and uniform application of force throughout the stroke. This method reduces the risk of tool breakage and workpiece deformation by minimizing compressive stresses. Pull broaching is especially advantageous for producing intricate internal profiles and maintaining tighter tolerances in precision machining operations.

Applications of Push Broaching

Push broaching is widely used in manufacturing for creating precise internal features such as keyways, splines, and hexagonal holes in softer materials like aluminum and brass. It is ideal for applications requiring high production rates and minimal tool wear, such as automotive and aerospace component machining. The push broach method excels in machining blind holes and complex profiles where controlled feed and accuracy are critical.

Applications of Pull Broaching

Pull broaching is widely used in applications requiring precise internal shapes such as keyways, splines, and slots in automotive and aerospace components. This method excels in machining materials with challenging hardness due to its consistent cutting force and reduced tool wear. Industries favor pull broaching for high-volume production runs where accuracy and surface finish are critical.

Selecting the Right Broaching Method

Selecting the right broaching method depends on workpiece material, desired finish, and machine setup. Push broaching suits softer materials and offers higher speeds but requires more robust fixturing and precise alignment. Pull broaching excels with harder metals and deeper cuts, providing better control and less risk of workpiece distortion.

Conclusion: Choosing Push vs Pull Broach

Choosing between push broach and pull broach depends on material type, part shape, and precision requirements. Push broach offers simplicity and is suitable for less complex profiles and softer materials, whereas pull broach provides higher accuracy and better surface finish, ideal for harder materials and intricate geometries. Evaluating production volume and tooling costs also influences the optimal broaching method for specific manufacturing needs.

Push broach vs pull broach Infographic

libmatt.com

libmatt.com