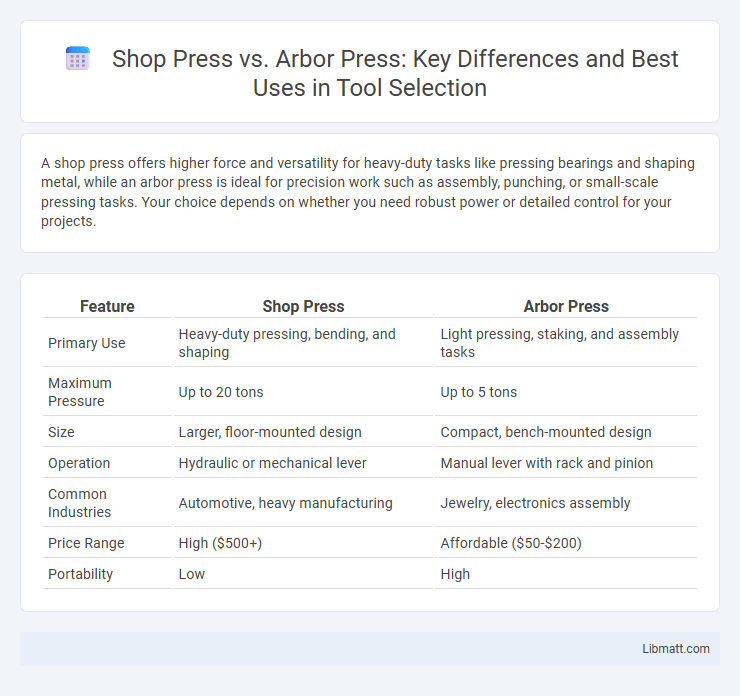

A shop press offers higher force and versatility for heavy-duty tasks like pressing bearings and shaping metal, while an arbor press is ideal for precision work such as assembly, punching, or small-scale pressing tasks. Your choice depends on whether you need robust power or detailed control for your projects.

Table of Comparison

| Feature | Shop Press | Arbor Press |

|---|---|---|

| Primary Use | Heavy-duty pressing, bending, and shaping | Light pressing, staking, and assembly tasks |

| Maximum Pressure | Up to 20 tons | Up to 5 tons |

| Size | Larger, floor-mounted design | Compact, bench-mounted design |

| Operation | Hydraulic or mechanical lever | Manual lever with rack and pinion |

| Common Industries | Automotive, heavy manufacturing | Jewelry, electronics assembly |

| Price Range | High ($500+) | Affordable ($50-$200) |

| Portability | Low | High |

Introduction to Shop Press vs Arbor Press

Shop presses and arbor presses serve distinct purposes in metalworking and mechanical shops, with shop presses designed for higher force applications such as bending, forming, and assembly of heavy-duty parts, while arbor presses are intended for precision tasks like staking, punching, and light press fitting. The shop press typically features a hydraulic system capable of exerting several tons of force, making it ideal for larger-scale industrial use, whereas the arbor press is manually operated and suited for smaller, detailed work requiring controlled pressure. Understanding the capabilities of each press ensures you select the right tool for your specific workshop tasks, optimizing both efficiency and accuracy.

Key Differences Between Shop Press and Arbor Press

Shop presses utilize hydraulic power to exert high force, making them ideal for heavy-duty pressing, bending, and straightening tasks, while arbor presses operate manually or with mechanical leverage for lighter, precise assembly and pressing jobs. Shop presses are commonly larger, equipped with adjustable tables and greater stroke lengths, whereas arbor presses feature smaller frames suited for detailed work like staking, riveting, and broaching. The key differences lie in their power source, force capacity, size, and typical applications within manufacturing and repair environments.

Common Applications of Shop Presses

Shop presses are commonly used for tasks such as bending, straightening, and pressing bearings or bushings in automotive repair and metal fabrication shops. They excel in applying controlled force for assembly and disassembly operations, including installing or removing gears and shafts. These presses are versatile tools essential for maintenance and manufacturing processes requiring precise pressure application.

Typical Uses for Arbor Presses

Arbor presses are typically used for precise assembly tasks such as staking, riveting, and pressing bearings or bushings in place. They excel in metalworking and manufacturing applications where controlled force and accuracy are required. Your workshop benefits from an arbor press when performing light to moderate force operations that demand meticulous handling.

Force and Capacity Comparison

Shop presses typically generate forces ranging from 12 to 50 tons, making them suitable for heavy-duty tasks such as bending, straightening, and assembling large components. Arbor presses generally produce lower force, usually between 1 and 5 tons, and are designed for precision tasks like staking, riveting, and small assembly operations. The capacity difference reflects their intended use, with shop presses accommodating larger workpieces and higher force requirements, whereas arbor presses prioritize accuracy and control over smaller parts.

Space and Footprint Considerations

Shop presses typically require more workspace due to their larger frames and higher tonnage capacity, making them suitable for extensive heavy-duty tasks but less ideal for compact work areas. Arbor presses feature a smaller footprint, allowing for easier integration into limited spaces and benchtop setups, providing precision control for lighter pressing jobs. Choosing between them depends on your available space and the scale of pressing operations.

Precision and Control: Which Offers More?

Arbor presses typically provide greater precision and control due to their compact design and direct mechanical leverage, making them ideal for delicate tasks requiring fine adjustments. Shop presses, while powerful and capable of handling larger workpieces, often sacrifice some precision because of their hydraulic systems and larger frames. For applications demanding meticulous alignment and controlled force, an arbor press offers superior accuracy compared to the broader capacity of a shop press.

Cost and Maintenance Factors

Shop presses generally cost less upfront compared to arbor presses, making them a budget-friendly option for lighter tasks. Maintenance for shop presses is typically simpler and less frequent due to their straightforward hydraulic design, reducing long-term expenses. Arbor presses, while more expensive initially, require regular lubrication and occasional replacement of mechanical parts, impacting maintenance costs over time.

Safety Features and Best Practices

Shop presses and arbor presses both prioritize safety through built-in features such as overload protection and secure work-holding mechanisms to prevent accidents. Best practices for using these presses include wearing appropriate personal protective equipment (PPE), ensuring proper alignment of the workpiece, and regularly inspecting the equipment for wear or damage. Your careful adherence to these safety protocols significantly reduces the risk of injury and ensures efficient, reliable operation.

Choosing the Right Press for Your Workshop

Selecting the right press for your workshop depends on the type of tasks you frequently perform, with a shop press excelling in heavy-duty pressing, bending, and straightening due to its robust hydraulic system. An arbor press is ideal for precision work such as staking, riveting, and small assembly tasks, offering greater control for detailed operations. Your choice should align with the intensity and delicacy of jobs you handle to maximize efficiency and maintain tool longevity.

Shop press vs arbor press Infographic

libmatt.com

libmatt.com