A pipe cutter is designed for cutting thicker, heavier materials like steel or cast iron pipes, providing clean and precise cuts for plumbing or industrial applications. Your choice between a pipe cutter and a tube cutter depends on the material thickness and type, as tube cutters are better suited for thinner metals such as copper or aluminum tubing typically used in HVAC or refrigeration systems.

Table of Comparison

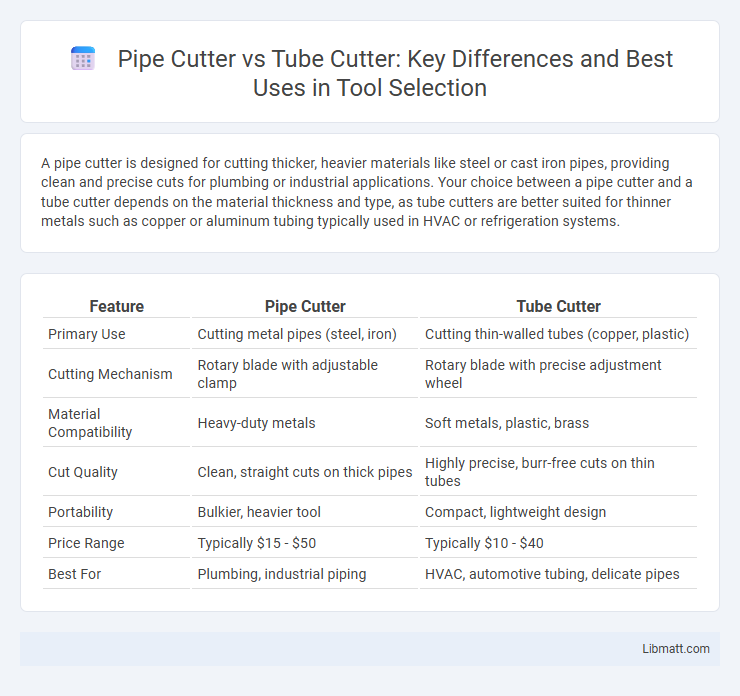

| Feature | Pipe Cutter | Tube Cutter |

|---|---|---|

| Primary Use | Cutting metal pipes (steel, iron) | Cutting thin-walled tubes (copper, plastic) |

| Cutting Mechanism | Rotary blade with adjustable clamp | Rotary blade with precise adjustment wheel |

| Material Compatibility | Heavy-duty metals | Soft metals, plastic, brass |

| Cut Quality | Clean, straight cuts on thick pipes | Highly precise, burr-free cuts on thin tubes |

| Portability | Bulkier, heavier tool | Compact, lightweight design |

| Price Range | Typically $15 - $50 | Typically $10 - $40 |

| Best For | Plumbing, industrial piping | HVAC, automotive tubing, delicate pipes |

Introduction to Pipe Cutters and Tube Cutters

Pipe cutters and tube cutters are precision tools designed to cleanly trim pipes and tubes, essential in plumbing, HVAC, and metalworking. Pipe cutters typically accommodate larger diameters and thicker materials, offering strong cutting wheels and adjustable grips for efficient handling of metallic pipes like steel or copper. Tube cutters, optimized for smaller-diameter tubing such as copper or stainless steel, provide smooth, burr-free cuts crucial for fluid or gas transport systems where a precise fit and seal are necessary.

Key Differences Between Pipe Cutters and Tube Cutters

Pipe cutters are specifically designed to cut through thicker and harder materials like steel and iron pipes, featuring a robust cutting wheel and adjustable jaw to handle larger diameters. Tube cutters excel at precision cutting of softer metals such as copper, aluminum, and brass, often incorporating a rotating cutter wheel and guide rollers to ensure clean, burr-free cuts. The main difference lies in their application and build: pipe cutters offer heavy-duty cutting power for plumbing and construction pipes, while tube cutters provide smoother finishes ideal for HVAC, refrigeration, and automotive tubing.

Materials Compatible with Pipe Cutters vs Tube Cutters

Pipe cutters are typically designed to handle thicker and harder materials such as steel, copper, and cast iron, making them ideal for heavy-duty plumbing and industrial applications. Tube cutters, on the other hand, are optimized for thinner-walled materials like soft copper, aluminum, brass, and plastic tubing, ensuring cleaner cuts and minimal deformation on delicate materials. Understanding the material compatibility of your cutting tool ensures precision and efficiency in your plumbing or HVAC projects.

How Pipe Cutters Work: Features and Mechanisms

Pipe cutters operate by clamping a sharp cutting wheel around the pipe and rotating it to score and gradually deepen a groove until the pipe is severed, utilizing adjustable jaws to accommodate various pipe diameters. Tube cutters often feature a ratcheting mechanism for precise control and smoother cuts, with a cutting wheel designed to minimize deformation on thinner-walled tubes compared to the usually sturdier pipe cutters. Both tools use a screw or ratchet system to apply consistent pressure, ensuring clean, straight cuts essential for plumbing, HVAC, and metalworking applications.

How Tube Cutters Work: Features and Mechanisms

Tube cutters operate using a rotary cutting wheel that gradually scores the tube's surface as the tool is rotated around it, applying consistent pressure to achieve a clean, precise cut. Key features include an adjustable jaw or clamp to secure tubes of varying diameters and a tightening mechanism, often a knob or screw, which controls the pressure exerted by the cutting wheel. This design minimizes deformation and allows for smooth cuts on materials like copper, aluminum, and plastic tubing, making tube cutters essential for plumbing and HVAC tasks.

Precision and Cutting Quality Comparison

Pipe cutters provide high precision and smooth cutting edges, ideal for larger diameter pipes with thicker walls, ensuring minimal deformation during cuts. Tube cutters excel in delivering clean, burr-free cuts on thinner, smaller-diameter tubes, offering superior accuracy for delicate applications. Both tools optimize cutting quality based on material thickness and application, with pipe cutters better suited for heavy-duty use and tube cutters preferred for finesse and detail.

Speed and Efficiency of Each Tool

Pipe cutters generally offer faster cutting speeds on thicker or larger diameter pipes due to their robust construction and ratcheting mechanism, making them ideal for heavy-duty applications. Tube cutters excel in precision and efficiency on smaller diameter tubes, providing clean, burr-free cuts with minimal effort, which reduces the need for additional finishing. Choosing between the two depends on the material thickness and required cutting accuracy, as pipe cutters maximize speed for large pipes, while tube cutters enhance efficiency in delicate or tight spaces.

Pros and Cons: Pipe Cutters vs Tube Cutters

Pipe cutters offer clean, precise cuts ideal for larger diameter pipes made of materials like steel and copper, but they can be bulky and less effective on smaller tubes or thin-walled materials. Tube cutters excel in handling smaller diameters and delicate materials without deforming the tube, providing smooth edges ideal for plumbing or HVAC work, although they may struggle with very thick pipes. Your choice depends on the project's pipe or tube size and material, balancing tool portability against cutting precision and ease of use.

Choosing the Right Tool for Your Project

Selecting between a pipe cutter and a tube cutter depends on the material type and diameter involved in your project, as pipe cutters are designed for thicker, galvanized, or steel pipes, whereas tube cutters excel with thinner materials like copper or plastic tubes. Your choice impacts the precision and quality of cuts; pipe cutters typically handle larger, tougher pipes but can be less precise, while tube cutters provide clean, burr-free edges essential for plumbing or HVAC applications. Understanding the specific requirements of your tubing system ensures you use the right tool, optimizing efficiency and preventing damage to your materials.

Maintenance Tips for Longevity and Performance

Pipe cutters and tube cutters require regular maintenance to ensure longevity and optimal performance. Clean the cutting wheels and blades after each use to remove debris and prevent rust, while lubricating moving parts with light machine oil to maintain smooth operation. You can extend the life of your tool by inspecting and replacing worn blades promptly, storing it in a dry place, and calibrating the cutting mechanism for consistent, precise cuts.

Pipe cutter vs tube cutter Infographic

libmatt.com

libmatt.com