Counterbore holes create a flat-bottomed recess allowing the bolt head to sit flush with or below the surface, while countersink holes feature a conical shape designed for flathead screws to sit flush. Understanding the difference ensures your fasteners fit perfectly, improving both the appearance and functionality of your project.

Table of Comparison

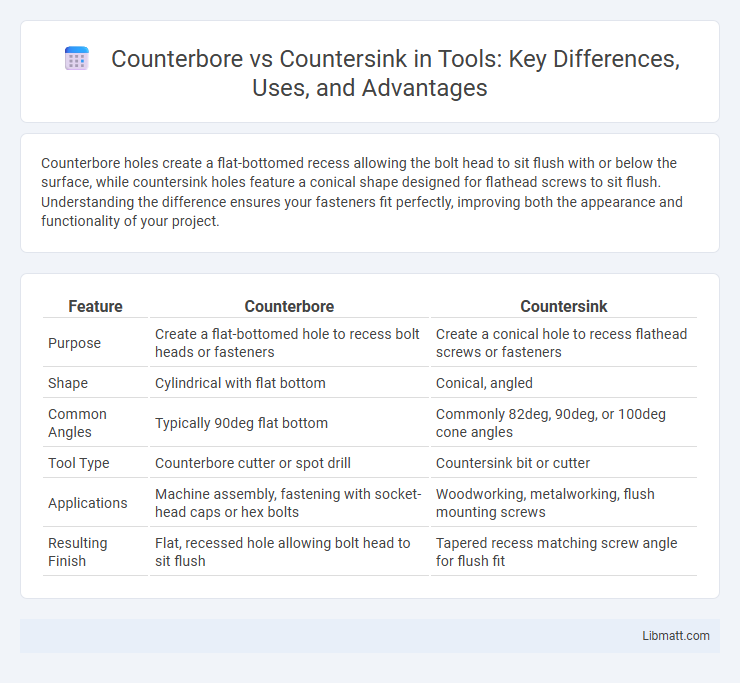

| Feature | Counterbore | Countersink |

|---|---|---|

| Purpose | Create a flat-bottomed hole to recess bolt heads or fasteners | Create a conical hole to recess flathead screws or fasteners |

| Shape | Cylindrical with flat bottom | Conical, angled |

| Common Angles | Typically 90deg flat bottom | Commonly 82deg, 90deg, or 100deg cone angles |

| Tool Type | Counterbore cutter or spot drill | Countersink bit or cutter |

| Applications | Machine assembly, fastening with socket-head caps or hex bolts | Woodworking, metalworking, flush mounting screws |

| Resulting Finish | Flat, recessed hole allowing bolt head to sit flush | Tapered recess matching screw angle for flush fit |

Introduction to Counterbores and Countersinks

Counterbores create a flat-bottomed hole, allowing fastener heads to sit flush or below the surface, typically used with socket head cap screws and bolts. Countersinks form a conical hole that matches the taper of standard flat-head screws, ensuring a smooth, flush finish on the material surface. Both techniques enhance mechanical assembly aesthetics and functionality by providing secure, even seating for different fastener types.

Definition of Counterbore

Counterbore is a machining process that creates a flat-bottomed hole larger in diameter than the original hole to allow the head of a fastener, such as a socket-head cap screw, to sit flush or below the surface. This feature enables a secure and precise fit in assembly applications requiring fasteners to be recessed, improving both aesthetics and function. Unlike countersink, which shapes a conical hole for flat-head screws, counterbore emphasizes a cylindrical recess with a square edge for socket-head or hex bolts.

Definition of Countersink

A countersink is a conical hole cut into a material to allow the head of a screw or bolt to sit flush with or below the surface. Unlike counterbores, countersinks create an angled recess designed for flat-headed or tapered screws. Understanding the definition of countersink helps you choose the right tool for achieving a smooth, professional finish on your project.

Key Differences Between Counterbore and Countersink

Counterbore creates a flat-bottomed hole to accommodate the head of a socket head cap screw, ensuring the fastener sits flush or below the surface, while countersink forms a conical hole designed for flathead screws to sit flush with the material. Counterbore holes have precise diameter and depth specifications matching the screw head dimensions, whereas countersink holes are defined by the included angle, typically 82deg or 90deg, to match the screw head angle. The key difference lies in the shape and purpose: counterbores provide a recessed area for cylindrical screw heads, and countersinks create angled recesses for tapered screw heads.

Applications of Counterbores

Counterbores are primarily used in applications where a fastener, such as a bolt or socket head cap screw, needs to be recessed flush with or below the surface of the workpiece, providing a clean and professional finish. These are essential in assembly tasks requiring precision and strength, such as machinery assembly and automotive manufacturing, where maintaining surface integrity prevents interference with moving parts. Your projects benefit from counterbores when securing components without compromising structural alignment or aesthetics.

Applications of Countersinks

Countersinks are commonly used in woodworking, metalworking, and manufacturing to create a conical hole allowing flathead screws to sit flush with or below the surface of the material. Your project benefits from countersinks when aesthetics and smooth surface finishes are essential, such as in cabinetry, furniture assembly, and aerospace components. These applications improve screw alignment, reduce material stress, and enhance the overall appearance of the final product.

Tools Required for Counterboring and Countersinking

Counterboring requires a counterbore tool or a pilot drill combined with a counterbore cutter to create a flat-bottomed hole for bolt heads or fasteners, often used with a drill press or milling machine for precision. Countersinking uses a countersink bit, typically a conical-shaped cutter, to create a tapered hole that allows flathead screws to sit flush with or below the surface, compatible with handheld drills or drill presses. Both processes demand specific tooling to achieve the proper hole shape and ensure fasteners fit correctly in mechanical assemblies.

Material Compatibility for Each Process

Counterbore processes work well with harder materials like steel, stainless steel, and aluminum, providing precise, square-bottomed holes for socket head cap screws. Countersink techniques suit softer materials such as wood, plastic, and thin metal sheets, allowing fastener heads to sit flush or below the surface for a smooth finish. You should choose the process based on your material's hardness and the required hole profile to ensure optimal fastening and structural integrity.

Advantages and Disadvantages Comparison

Counterbores provide precise seating for fasteners with square edges, ensuring strong, flush connections ideal for heavy-duty applications, but they require more material removal and larger hole size, increasing complexity and cost. Countersinks create a tapered surface for flat-head screws, offering aesthetic flush finishes and easier alignment, though they may weaken surrounding material and provide less surface contact, reducing joint strength. Choosing between counterbore and countersink depends on balancing the need for structural integrity versus ease of installation and appearance.

Choosing Between Counterbore and Countersink

Choosing between a counterbore and countersink depends on the fastener head type and the required seating surface. Counterbores create a flat-bottomed hole, ideal for socket head cap screws, while countersinks produce a conical hole suited for flat-head screws. Assess the screw design and application surface to determine the appropriate hole geometry for secure and flush fastening.

Counterbore vs countersink Infographic

libmatt.com

libmatt.com