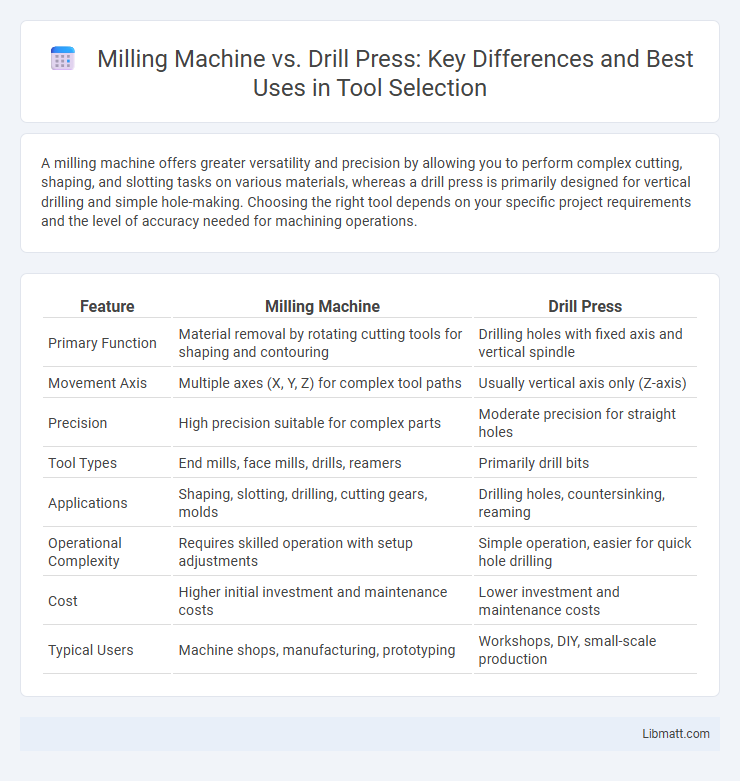

A milling machine offers greater versatility and precision by allowing you to perform complex cutting, shaping, and slotting tasks on various materials, whereas a drill press is primarily designed for vertical drilling and simple hole-making. Choosing the right tool depends on your specific project requirements and the level of accuracy needed for machining operations.

Table of Comparison

| Feature | Milling Machine | Drill Press |

|---|---|---|

| Primary Function | Material removal by rotating cutting tools for shaping and contouring | Drilling holes with fixed axis and vertical spindle |

| Movement Axis | Multiple axes (X, Y, Z) for complex tool paths | Usually vertical axis only (Z-axis) |

| Precision | High precision suitable for complex parts | Moderate precision for straight holes |

| Tool Types | End mills, face mills, drills, reamers | Primarily drill bits |

| Applications | Shaping, slotting, drilling, cutting gears, molds | Drilling holes, countersinking, reaming |

| Operational Complexity | Requires skilled operation with setup adjustments | Simple operation, easier for quick hole drilling |

| Cost | Higher initial investment and maintenance costs | Lower investment and maintenance costs |

| Typical Users | Machine shops, manufacturing, prototyping | Workshops, DIY, small-scale production |

Introduction: Milling Machine vs Drill Press

A milling machine offers versatile cutting capabilities with multiple axes for precise shaping, while a drill press primarily provides vertical drilling functions. Milling machines are ideal for complex tasks such as contouring and slotting, whereas drill presses excel in accurate hole drilling. Your choice depends on the specific machining needs and the complexity of the workpiece.

Key Differences Between Milling Machines and Drill Presses

Milling machines offer versatile capabilities, including precise cutting, shaping, and drilling of various materials through rotary cutters, while drill presses primarily focus on vertical drilling tasks with less complexity. Milling machines provide multi-axis movement for intricate contouring and slotting, contrasting with the fixed vertical motion of drill presses suited for straightforward hole drilling. The rigidity, power, and tooling options of milling machines exceed those of drill presses, making them essential for advanced machining operations in manufacturing and metalworking industries.

Design and Structure Comparison

Milling machines feature a robust, multifunctional design with a movable table that supports complex, three-axis workpiece manipulation, allowing precise shaping and cutting. Drill presses have a simpler structure with a fixed vertical spindle and a stationary table, mainly designed for drilling straight holes with consistent depth. Your choice depends on whether you require versatile milling capabilities or straightforward drilling operations.

Functionality and Capabilities

A milling machine offers advanced functionality with the ability to cut complex shapes, slots, and contours by moving the workpiece or cutting tool across multiple axes, enabling precision machining of metal and other materials. In comparison, a drill press is primarily designed for vertical drilling operations, focusing on creating round holes with limited movement and less versatility. Milling machines provide enhanced capabilities for shaping and finishing workpieces, while drill presses excel in straightforward, repetitive hole-making tasks.

Precision and Accuracy

Milling machines offer higher precision and accuracy compared to drill presses due to their ability to move the workpiece and tool along multiple axes with fine control, enabling complex, intricate cuts. Drill presses primarily provide vertical movement for straightforward drilling tasks, limiting their precision to basic hole-making operations. Your projects requiring detailed machining will benefit significantly from the superior accuracy of milling machines.

Suitable Materials for Each Machine

Milling machines are suitable for machining harder materials like steel, aluminum, and titanium due to their powerful spindles and precise control. Drill presses work best with softer materials such as wood, plastic, and light metals, providing efficient drilling without the need for complex tool paths. Your choice between the two should depend on the material hardness and the complexity of the machining operation required.

Typical Applications and Uses

Milling machines are typically employed for complex cutting, shaping, and contouring tasks on metal or other solid materials, often used in manufacturing parts with precise dimensions and intricate designs. Drill presses specialize in creating accurate holes of various sizes, making them ideal for drilling, reaming, and tapping operations in woodworking, metalworking, and fabrication shops. Both machines serve essential roles in machining processes but differ in capabilities and applications based on the complexity and type of work required.

Cost and Investment Considerations

Milling machines generally require a higher initial investment compared to drill presses due to their complex design and versatility in cutting operations. Maintenance and operational costs for milling machines tend to be greater because of their precision components and need for regular calibration. Drill presses offer a more cost-effective solution for simpler drilling tasks, making them ideal for budget-conscious workshops or projects with limited machining requirements.

Maintenance and Durability

Milling machines require regular lubrication and calibration to maintain precision, while drill presses primarily demand consistent motor checks and clean spindle maintenance for optimal performance. Durability of milling machines is enhanced by their robust construction and complex components, which withstand heavy-duty machining, whereas drill presses, being simpler devices, offer longevity through fewer moving parts and routine upkeep. Both machines benefit significantly from timely replacement of worn parts to ensure sustained operational efficiency and extended service life.

Which One Should You Choose?

A milling machine offers greater versatility and precision, making it suitable for complex shaping and cutting tasks, while a drill press specializes in creating accurate holes quickly and efficiently. Your choice depends on the specific needs of your project; if you require detailed machining with multiple operations, the milling machine is the ideal option, but for straightforward drilling tasks, the drill press provides faster and simpler operation. Consider factors such as the type of materials, desired accuracy, and workflow to determine which tool best aligns with your workshop requirements.

Milling machine vs drill press Infographic

libmatt.com

libmatt.com