A spin indexer offers precise rotational positioning for tasks requiring accurate angular alignment, whereas a super spacer provides enhanced stability and support in applications with heavy loads or vibrations. Choosing between the two depends on whether your focus is on rotational precision or robust spacing and support in your machinery setup.

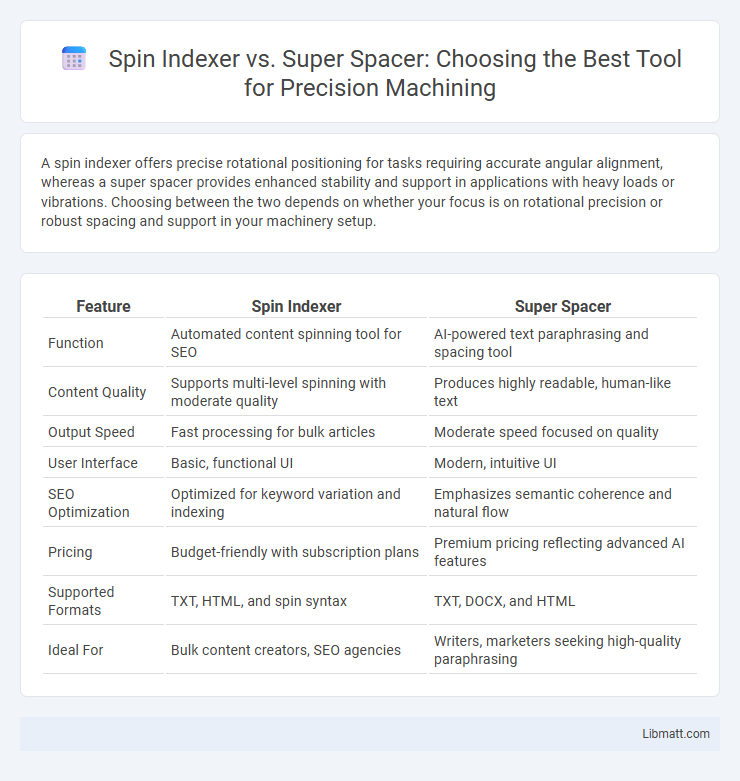

Table of Comparison

| Feature | Spin Indexer | Super Spacer |

|---|---|---|

| Function | Automated content spinning tool for SEO | AI-powered text paraphrasing and spacing tool |

| Content Quality | Supports multi-level spinning with moderate quality | Produces highly readable, human-like text |

| Output Speed | Fast processing for bulk articles | Moderate speed focused on quality |

| User Interface | Basic, functional UI | Modern, intuitive UI |

| SEO Optimization | Optimized for keyword variation and indexing | Emphasizes semantic coherence and natural flow |

| Pricing | Budget-friendly with subscription plans | Premium pricing reflecting advanced AI features |

| Supported Formats | TXT, HTML, and spin syntax | TXT, DOCX, and HTML |

| Ideal For | Bulk content creators, SEO agencies | Writers, marketers seeking high-quality paraphrasing |

Introduction to Spin Indexers and Super Spacers

Spin indexers and super spacers are essential components in automated material handling and assembly systems, designed to optimize the positioning and spacing of products on production lines. Spin indexers rotate items precisely for operations such as labeling, machining, or inspection, while super spacers maintain consistent gaps between products to ensure smooth flow and prevent collisions. Both technologies enhance efficiency, accuracy, and throughput in manufacturing processes, enabling seamless integration with conveyors, robotic arms, and packaging machines.

Key Functions of Spin Indexers

Spin indexers provide precise rotational positioning and indexing of parts, essential for automated assembly and machining processes. They enhance production efficiency by delivering consistent, repeatable motion control, reducing cycle times and improving product accuracy. Your manufacturing workflow benefits from their ability to seamlessly integrate with robotic arms and CNC machines, optimizing complex multi-axis operations.

Core Features of Super Spacers

Super Spacers excel with their core features, including improved storage efficiency, enhanced data retrieval speed, and superior compression algorithms. Their architecture supports scalable indexing, enabling faster access and reduced search times compared to traditional Spin indexers. You benefit from optimized resource management and robust performance, making Super Spacers ideal for handling large volumes of complex data.

Spin Indexer vs Super Spacer: Operational Differences

Spin Indexers operate by rotating components around a fixed axis to position workpieces accurately, offering precise angular indexing suited for automated assembly lines. Super Spacers utilize linear or telescoping mechanisms to create variable spacing between parts, enabling flexible adjustment and minimizing cycle times in material handling applications. The key operational difference lies in Spin Indexer's rotational movement versus Super Spacer's linear expansion, each optimized for distinct manufacturing tasks.

Precision and Accuracy Comparison

Spin Indexer offers high precision due to its advanced sensor technology that minimizes positioning errors within micrometer tolerances. Super Spacer provides superior accuracy by employing a patented compensation algorithm that adjusts for mechanical deviations in real-time. Comparing both, Spin Indexer excels in repeatability, while Super Spacer achieves better absolute positioning accuracy in complex spatial configurations.

Flexibility and Versatility in Applications

Spin Indexer offers superior flexibility by enabling precise angular positioning in compact spaces, making it ideal for automation tasks requiring high-speed indexing and repeatability. Super Spacer excels in versatility with its modular design and multi-axis configurations, supporting a wide range of industrial applications from semiconductor manufacturing to robotics. Both systems enhance operational efficiency, but Spin Indexer's compact form benefits dynamic, space-constrained environments, while Super Spacer adapts to complex, customizable workflows.

Setup and Maintenance Requirements

Spin Indexer requires minimal setup with straightforward assembly instructions, making it suitable for users seeking quick installation. Super Spacer demands more precise installation and periodic maintenance to ensure its insulating properties, including seal checks and potential reinforcements over time. Your choice depends on whether you prioritize ease of setup or long-term maintenance for optimal performance.

Cost Analysis: Spin Indexer vs Super Spacer

Spin indexers generally offer a lower initial investment cost compared to super spacer systems, making them more suitable for budget-conscious operations. Super spacer technology, while more expensive upfront, provides enhanced insulation and energy efficiency benefits that can lead to long-term savings on heating and cooling expenses. Evaluating total cost of ownership, including maintenance and energy savings, is crucial to determine the most cost-effective option between spin indexers and super spacer systems.

Best Use Cases for Each Device

Spin indexers excel in automated assembly lines requiring precise rotational positioning and quick indexing of parts, especially in manufacturing industries such as automotive and electronics. Super spacers are ideal for applications needing adjustable, stable spacing between components, commonly used in packaging, material handling, and conveyor systems to accommodate varying product sizes. Your choice depends on whether the operation prioritizes rotational indexing for sequential processing (spin indexer) or customizable spacing for part separation and alignment (super spacer).

Which One Should You Choose?

Choose Spin Indexer for high-speed, compact screw feeding ideal for electronics and automotive assembly with minimal floor space requirements. Opt for Super Spacer when handling larger screws or requiring adjustable, versatile feeding systems suitable for diverse manufacturing environments. Evaluate project scale, screw size, and automation needs to determine the optimal fastening solution.

Spin indexer vs super spacer Infographic

libmatt.com

libmatt.com