Airless sprayers deliver paint by pumping it at high pressure through a small nozzle, creating a fine, consistent spray without the need for compressed air, making them ideal for large surface areas and faster coverage. Your choice between an airless and air sprayer depends on the project's size, desired finish quality, and equipment portability.

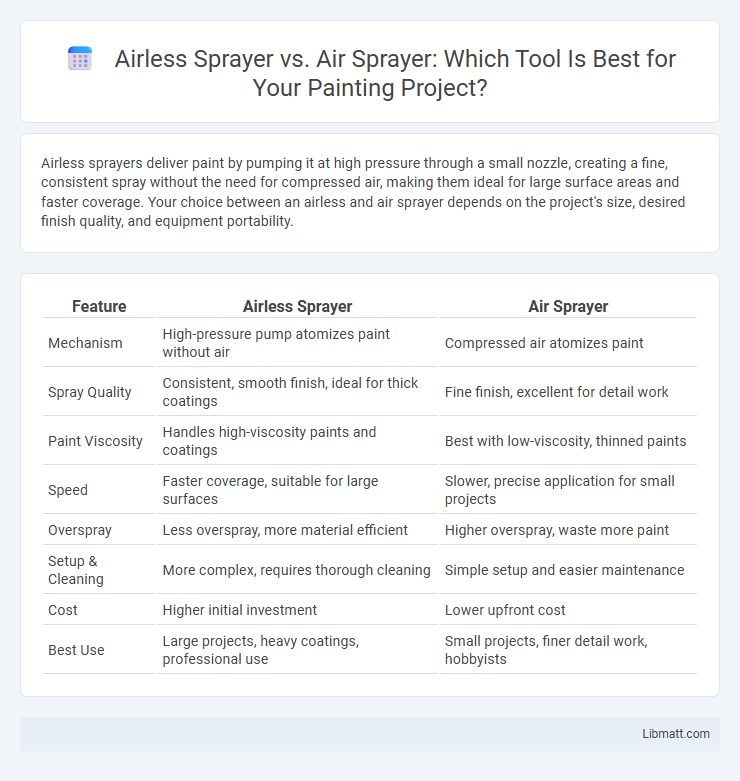

Table of Comparison

| Feature | Airless Sprayer | Air Sprayer |

|---|---|---|

| Mechanism | High-pressure pump atomizes paint without air | Compressed air atomizes paint |

| Spray Quality | Consistent, smooth finish, ideal for thick coatings | Fine finish, excellent for detail work |

| Paint Viscosity | Handles high-viscosity paints and coatings | Best with low-viscosity, thinned paints |

| Speed | Faster coverage, suitable for large surfaces | Slower, precise application for small projects |

| Overspray | Less overspray, more material efficient | Higher overspray, waste more paint |

| Setup & Cleaning | More complex, requires thorough cleaning | Simple setup and easier maintenance |

| Cost | Higher initial investment | Lower upfront cost |

| Best Use | Large projects, heavy coatings, professional use | Small projects, finer detail work, hobbyists |

Introduction to Airless and Air Sprayers

Airless sprayers use high pressure to atomize paint, delivering a smooth, even coat without the need for compressed air, making them ideal for large surface areas and thick coatings. Air sprayers rely on compressed air to break the paint into smaller droplets, allowing for detailed, finer finishes often preferred in automotive or furniture painting. Your choice between an airless sprayer and an air sprayer depends on the project scale, paint type, and finish quality desired.

How Airless Sprayers Work

Airless sprayers operate by pumping paint at extremely high pressure through a small nozzle, atomizing the paint into a fine spray without using compressed air. This process allows for a consistent, high-volume output ideal for covering large surfaces quickly and evenly. The high pressure ensures better adhesion and a smoother finish, making airless sprayers a preferred choice for exterior and interior painting projects.

How Air Sprayers Operate

Air sprayers operate by using compressed air to atomize paint into fine droplets, creating a controlled spray pattern ideal for detailed work and smooth finishes. This method allows for precise application on surfaces, especially in automotive or furniture painting, where uniform coverage is crucial. Understanding how air sprayers function helps you select the right tool for projects needing finesse and minimal material waste.

Key Differences Between Airless and Air Sprayers

Airless sprayers operate by pumping paint at very high pressure through a tiny nozzle, creating a fine mist ideal for thick coatings and large surfaces without requiring compressed air. Air sprayers use compressed air to atomize the paint, providing greater control and a smoother finish suitable for detailed work and lighter coatings. The primary differences lie in pressure mechanism, spray quality, and application speed, making airless sprayers better for high-volume projects and air sprayers preferable for precision and finish quality.

Surface Finish Quality Comparison

Airless sprayers deliver a thicker, more uniform coat by spraying paint at high pressure without air, resulting in a smooth, durable finish ideal for large surfaces and textured materials. Air sprayers use compressed air to atomize paint, producing a finer mist that excels in achieving detailed, precise finishes on intricate or delicate projects. The choice between airless and air sprayers significantly affects surface finish quality, with airless sprayers preferred for speed and coverage, and air sprayers favored for crisp edges and minimal overspray.

Application Speed and Efficiency

Airless sprayers deliver paint at high pressure without the use of compressed air, resulting in faster application speeds and higher material transfer efficiency compared to air sprayers. Air sprayers rely on compressed air to atomize paint, which can produce more overspray and slower coverage rates. Consequently, airless sprayers are preferred for large-scale projects demanding quick, uniform application with minimal waste.

Suitability for Different Paint Types

Airless sprayers excel with thick, high-viscosity paints like latex and heavy coatings, providing a smooth, even finish by atomizing paint at high pressure without thinning. Air sprayers suit thinner, low-viscosity paints such as lacquers and enamels, offering precise control and fine atomization ideal for detailed work and delicate surfaces. Choosing between airless and air sprayers depends on paint viscosity and surface requirements, impacting application efficiency and final appearance.

Maintenance and Cleaning Requirements

Airless sprayers require thorough cleaning after each use to prevent nozzle clogs and maintain optimal pressure but typically involve fewer parts to disassemble than air sprayers. Air sprayers demand more frequent cleaning of the air cap, fluid tip, and needle to avoid paint buildup, which can affect spray quality and consistency. Your choice should consider the time and effort you are willing to invest in maintenance, as airless sprayers generally offer quicker cleanup but require careful attention to fluid filters.

Cost Comparison and Budget Considerations

Airless sprayers generally have a higher initial purchase cost, ranging from $200 to $1,500 depending on power and capacity, compared to air sprayers, which typically cost between $100 and $400. Maintenance expenses for airless sprayers can be greater due to complex parts, while air sprayers often require more frequent paint thinning, impacting material costs. Budget considerations should include long-term efficiency benefits of airless systems for large projects versus the affordability and simplicity of air sprayers for smaller, occasional tasks.

Choosing the Right Sprayer for Your Project

Choosing the right sprayer depends on your project's size and surface type; airless sprayers deliver high pressure for fast, even coverage on large areas, while air sprayers offer finer atomization ideal for detailed, smooth finishes on smaller or intricate surfaces. Airless sprayers minimize overspray and are suited for painting fences, walls, or decks efficiently, whereas air sprayers excel in delivering precise control for cabinets, furniture, or automotive painting. Your choice should balance efficiency, finish quality, and the specific requirements of your painting project.

Airless sprayer vs air sprayer Infographic

libmatt.com

libmatt.com