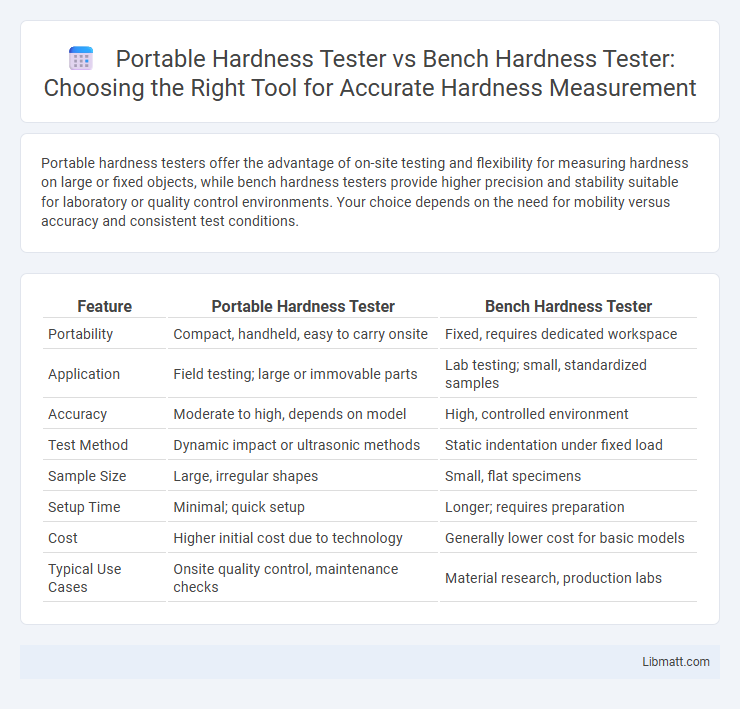

Portable hardness testers offer the advantage of on-site testing and flexibility for measuring hardness on large or fixed objects, while bench hardness testers provide higher precision and stability suitable for laboratory or quality control environments. Your choice depends on the need for mobility versus accuracy and consistent test conditions.

Table of Comparison

| Feature | Portable Hardness Tester | Bench Hardness Tester |

|---|---|---|

| Portability | Compact, handheld, easy to carry onsite | Fixed, requires dedicated workspace |

| Application | Field testing; large or immovable parts | Lab testing; small, standardized samples |

| Accuracy | Moderate to high, depends on model | High, controlled environment |

| Test Method | Dynamic impact or ultrasonic methods | Static indentation under fixed load |

| Sample Size | Large, irregular shapes | Small, flat specimens |

| Setup Time | Minimal; quick setup | Longer; requires preparation |

| Cost | Higher initial cost due to technology | Generally lower cost for basic models |

| Typical Use Cases | Onsite quality control, maintenance checks | Material research, production labs |

Introduction to Hardness Testing

Hardness testing measures a material's resistance to deformation, crucial for quality control in manufacturing and engineering applications. Portable hardness testers offer the advantage of on-site, non-destructive testing, allowing you to quickly assess hardness in field conditions. Bench hardness testers provide higher precision and repeatability in controlled lab environments, making them suitable for detailed material characterization and research purposes.

Overview of Portable Hardness Testers

Portable hardness testers offer on-site material testing with ease, providing instant hardness readings without the need to transport samples to a laboratory. Their compact design and battery-powered operation make them ideal for field inspections and quality control in manufacturing environments. You benefit from fast, non-destructive testing capability and the flexibility to evaluate large or fixed components directly where they are.

Overview of Bench Hardness Testers

Bench hardness testers are precision instruments mounted on a stable platform, designed for consistent and accurate hardness measurements in a controlled environment. They utilize various testing methods such as Rockwell, Brinell, or Vickers to evaluate material hardness with high repeatability and minimal operator variability. Ideal for laboratory settings, these testers handle a wide range of sample sizes and are favored for their durability and precision in quality control processes.

Testing Principles and Technologies Compared

Portable hardness testers utilize dynamic testing principles such as rebound or Leeb methods, allowing quick, non-destructive measurements on-site with minimal surface preparation. Bench hardness testers rely on static indentation techniques like Rockwell, Brinell, or Vickers, applying controlled force through fixed indenters for highly precise and repeatable results in a laboratory setting. Your choice depends on whether you need mobility and speed with portable devices or consistent accuracy and detailed analysis from bench testers.

Accuracy and Reliability Differences

Portable hardness testers offer convenience but may have slightly lower accuracy and reliability compared to bench hardness testers due to their susceptibility to operator handling and environmental conditions. Bench hardness testers typically provide higher precision with consistent force application and controlled testing conditions, resulting in more reliable measurements for critical applications. Your choice depends on whether portability or maximum accuracy and reliability is the priority for your hardness testing needs.

Portability and Flexibility Considerations

Portable hardness testers offer unmatched portability and flexibility, enabling on-site measurements across various locations without the need for specimen transport. Bench hardness testers, while providing higher precision in a controlled environment, lack mobility and are best suited for repetitive testing on fixed samples. Your choice depends on whether convenience in the field or precise, stable testing conditions is the priority.

Application Scenarios and Suitability

Portable hardness testers offer versatility for on-site testing in various industries like manufacturing, construction, and maintenance, allowing you to quickly assess material hardness in locations where moving the workpiece is impractical. Bench hardness testers provide higher accuracy and repeatability in controlled environments such as laboratories and quality control departments, ideal for detailed analysis of small to medium-sized samples. Selecting between the two depends on your need for mobility versus precision, with portable models suited for field inspections and bench testers for rigorous, standardized testing.

Cost and Maintenance Comparison

Portable hardness testers generally have a lower upfront cost than bench hardness testers, making them more accessible for small businesses or fieldwork. Maintenance for portable testers tends to be simpler and less frequent, as they lack complex fixtures and power systems found in bench models. Your choice depends on balancing initial investment and ongoing upkeep with the specific testing environment and frequency.

User Experience and Ease of Operation

Portable hardness testers offer superior user experience through lightweight design and handheld operation, allowing measurements in tight or remote spaces where bench testers are impractical. Bench hardness testers, while providing higher precision and stable setups, require a fixed workspace and more complex calibration, which can limit ease of use for non-specialists. Your choice depends on the need for mobility and quick testing versus the demand for consistent, laboratory-grade hardness data.

Choosing the Right Hardness Tester for Your Needs

Portable hardness testers provide convenience and flexibility for on-site material testing, making them ideal for inspecting large or immovable objects. Bench hardness testers offer higher precision and stability, suitable for laboratory environments requiring consistent and repeatable measurements. Consider your testing environment, sample size, and accuracy requirements to choose the right hardness tester for your needs.

Portable hardness tester vs bench hardness tester Infographic

libmatt.com

libmatt.com