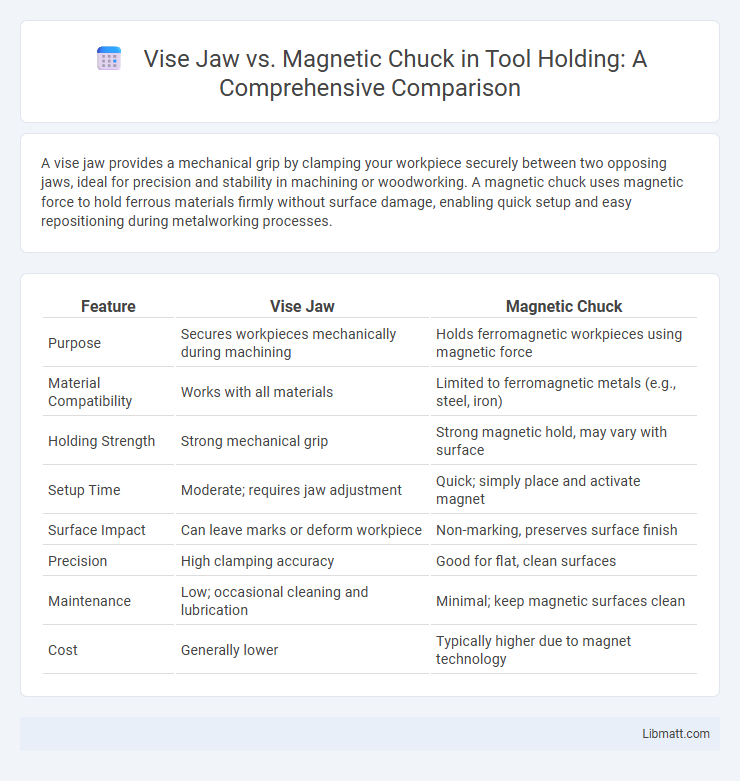

A vise jaw provides a mechanical grip by clamping your workpiece securely between two opposing jaws, ideal for precision and stability in machining or woodworking. A magnetic chuck uses magnetic force to hold ferrous materials firmly without surface damage, enabling quick setup and easy repositioning during metalworking processes.

Table of Comparison

| Feature | Vise Jaw | Magnetic Chuck |

|---|---|---|

| Purpose | Secures workpieces mechanically during machining | Holds ferromagnetic workpieces using magnetic force |

| Material Compatibility | Works with all materials | Limited to ferromagnetic metals (e.g., steel, iron) |

| Holding Strength | Strong mechanical grip | Strong magnetic hold, may vary with surface |

| Setup Time | Moderate; requires jaw adjustment | Quick; simply place and activate magnet |

| Surface Impact | Can leave marks or deform workpiece | Non-marking, preserves surface finish |

| Precision | High clamping accuracy | Good for flat, clean surfaces |

| Maintenance | Low; occasional cleaning and lubrication | Minimal; keep magnetic surfaces clean |

| Cost | Generally lower | Typically higher due to magnet technology |

Introduction to Workholding Solutions

Vise jaws and magnetic chucks serve as essential workholding solutions in machining, providing stability and precision during operations. Vise jaws mechanically clamp your workpiece with adjustable grip strength, ideal for irregular shapes and high-force applications. Magnetic chucks use powerful magnets to secure ferromagnetic materials quickly and without deformation, enhancing efficiency in repetitive tasks.

Overview of Vise Jaws

Vise jaws are precision-engineered clamping components designed to securely hold workpieces in place during machining, grinding, or assembly processes. They come in various materials such as hardened steel, cast iron, or soft jaw materials, tailored to protect delicate surfaces while providing maximum grip. Your choice of vise jaws directly impacts machining accuracy and efficiency, making them essential for stable and reliable workholding solutions.

Overview of Magnetic Chucks

Magnetic chucks provide a powerful and efficient solution for holding ferromagnetic workpieces during machining, utilizing permanent or electromagnets to generate a strong magnetic field that secures the material without mechanical clamps. These chucks offer precise positioning, rapid setup times, and enhanced surface access, minimizing distortion and improving machining accuracy compared to traditional vise jaws. Their versatility suits applications in grinding, milling, and turning, especially for thin, delicate, or irregularly shaped parts that require consistent holding force and reduced handling.

Key Differences Between Vise Jaws and Magnetic Chucks

Vise jaws provide mechanical clamping by physically gripping the workpiece, offering strong, adjustable pressure suitable for irregular shapes and heavier machining tasks. Magnetic chucks use magnetic force to hold ferromagnetic materials securely without physical clamps, enabling quick setup and excellent surface access during precision grinding or light milling. The choice depends on the workpiece material, required holding strength, and machining operation, with vise jaws favored for versatility and magnetic chucks preferred for flat, ferromagnetic parts needing unobstructed machining.

Strengths and Limitations of Vise Jaws

Vise jaws offer strong and secure clamping for irregularly shaped or delicate workpieces, providing excellent grip without causing damage. However, their effectiveness may be limited by jaw size and material compatibility, making them less suitable for extremely heavy or magnetic materials. Your choice of vise jaws should consider the specific workpiece geometry and the required holding force to ensure optimal performance.

Strengths and Limitations of Magnetic Chucks

Magnetic chucks provide strong, uniform holding force ideal for ferrous metal workpieces, enabling quick setup and efficient machining without mechanical clamping. Their primary limitation is ineffectiveness on non-ferrous materials and reduced grip on uneven or non-flat surfaces. Magnetic chucks also require power sources for electromagnets and careful handling to avoid demagnetization or residual magnetism in the workpiece.

Applications Best Suited for Vise Jaws

Vise jaws are best suited for securely holding irregularly shaped or delicate workpieces during milling, drilling, and grinding operations where precise clamping force is required. They provide versatility in machining wood, metal, and plastic components, especially when custom grips are needed to prevent movement or damage. Your ability to adjust and customize vise jaw inserts makes them ideal for non-ferrous materials and precision toolmaking tasks that demand stable, hands-on control.

Applications Best Suited for Magnetic Chucks

Magnetic chucks are ideal for holding ferromagnetic materials during precision grinding, welding, and machining processes, providing a uniform and secure grip without surface damage. They excel in applications requiring quick setup and release, such as repetitive jobs in manufacturing environments, enhancing efficiency and accuracy. Your choice of a magnetic chuck is beneficial when working with flat, smooth metal parts needing consistent holding power without mechanical clamping marks.

Safety Considerations and Maintenance

Vise jaws offer secure clamping with reduced risk of workpiece slippage but require regular inspection to prevent wear and ensure consistent grip, directly impacting operator safety. Magnetic chucks provide hands-free holding with no mechanical clamping force, minimizing crush hazards but necessitate routine cleaning to maintain magnetic strength and avoid debris interference, essential for safe and efficient operation. Proper maintenance protocols for both tools, including timely replacement of worn parts and surface cleaning, significantly enhance workplace safety and equipment longevity.

Choosing the Right Workholding Device for Your Needs

Choosing between a vise jaw and a magnetic chuck depends on the material type and precision required for your project. Vise jaws offer strong mechanical clamping suitable for irregularly shaped or heavy workpieces, while magnetic chucks provide quick, even holding for ferromagnetic materials without surface marring. Your choice should consider factors like workpiece size, machining operations, and the need for quick setup or maximum rigidity.

Vise jaw vs magnetic chuck Infographic

libmatt.com

libmatt.com